Zinc offers excellent corrosion resistance, making it ideal for protective coatings in various applications, especially in harsh environments. While its conductivity is lower than metals like copper or aluminum, zinc's balance of moderate electrical conductivity and superior corrosion resistance makes it suitable for specific electrical components exposed to moisture or corrosive elements. This combination extends the lifespan of equipment by preventing rust without significantly compromising electrical performance.

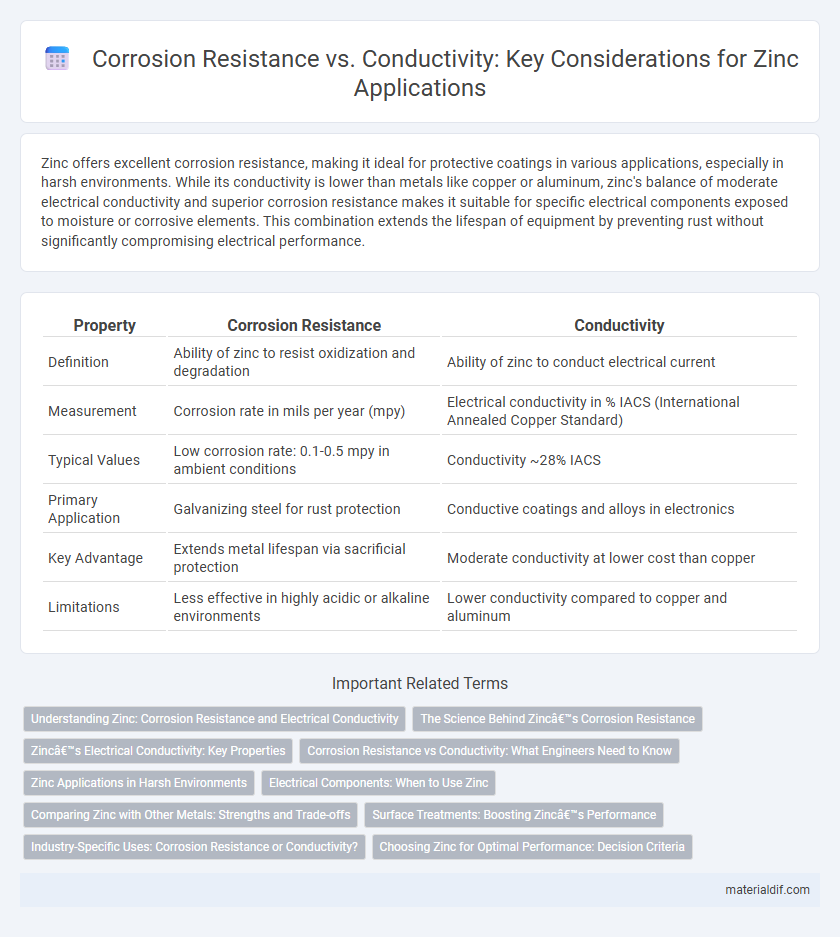

Table of Comparison

| Property | Corrosion Resistance | Conductivity |

|---|---|---|

| Definition | Ability of zinc to resist oxidization and degradation | Ability of zinc to conduct electrical current |

| Measurement | Corrosion rate in mils per year (mpy) | Electrical conductivity in % IACS (International Annealed Copper Standard) |

| Typical Values | Low corrosion rate: 0.1-0.5 mpy in ambient conditions | Conductivity ~28% IACS |

| Primary Application | Galvanizing steel for rust protection | Conductive coatings and alloys in electronics |

| Key Advantage | Extends metal lifespan via sacrificial protection | Moderate conductivity at lower cost than copper |

| Limitations | Less effective in highly acidic or alkaline environments | Lower conductivity compared to copper and aluminum |

Understanding Zinc: Corrosion Resistance and Electrical Conductivity

Zinc offers exceptional corrosion resistance by forming a protective oxide layer, making it ideal for galvanizing steel in automotive and construction industries. Its moderate electrical conductivity, approximately 16.6 million Siemens per meter, supports applications in batteries and electronic components without compromising durability. Balancing corrosion resistance and conductivity allows zinc to serve effectively in protective coatings and conductive parts where both properties are critical.

The Science Behind Zinc’s Corrosion Resistance

Zinc's exceptional corrosion resistance stems from its ability to form a stable, adherent layer of zinc carbonate when exposed to air, which acts as a protective barrier against further oxidation. This passive film slows down the electrochemical reactions responsible for metal degradation, extending the lifespan of galvanized steel and other zinc-coated materials. Despite its moderate electrical conductivity, zinc's protective properties make it an ideal choice for applications requiring durability in harsh environments, such as construction and automotive industries.

Zinc’s Electrical Conductivity: Key Properties

Zinc exhibits moderate electrical conductivity, approximately 16.6% that of copper, making it suitable for specific electrical applications where corrosion resistance is also crucial. Its ability to form a protective oxide layer enhances durability in harsh environments, preventing degradation without significantly compromising conductivity. These key properties position zinc as an ideal material for components such as connectors, terminals, and protective coatings in electrical systems exposed to corrosive conditions.

Corrosion Resistance vs Conductivity: What Engineers Need to Know

Zinc offers exceptional corrosion resistance which makes it ideal for protective coatings in construction and automotive industries, yet its electrical conductivity is relatively low compared to copper or aluminum. Engineers must balance zinc's durability benefits with its limited conductivity when designing electrical components or grounding systems. Selecting zinc alloys can optimize corrosion protection while moderately enhancing conductivity for specific application requirements.

Zinc Applications in Harsh Environments

Zinc's exceptional corrosion resistance makes it ideal for protective coatings in harsh environments such as marine and industrial settings, preventing rust on steel structures. Its moderate electrical conductivity supports applications like grounding systems and battery anodes where corrosion resistance and conductivity are critical. Zinc alloys combine durability and conductivity, enhancing performance in offshore platforms and chemical processing equipment exposed to aggressive conditions.

Electrical Components: When to Use Zinc

Zinc offers moderate electrical conductivity, making it suitable for electrical components where corrosion resistance is essential but high conductivity is not critical. Its excellent corrosion resistance protects connectors, terminals, and housings in harsh environments, extending component lifespan and reliability. Zinc alloys balance durability and conductive properties, often preferred in automotive and industrial electrical applications requiring robust protection against oxidation.

Comparing Zinc with Other Metals: Strengths and Trade-offs

Zinc offers exceptional corrosion resistance due to its ability to form a protective oxide layer, outperforming metals like steel and aluminum in harsh environments. While zinc's electrical conductivity is lower than copper and aluminum, its durability and resistance to oxidation make it ideal for coating applications such as galvanization. The trade-off between zinc's moderate conductivity and superior corrosion protection suits it for structural components requiring longevity rather than high electrical performance.

Surface Treatments: Boosting Zinc’s Performance

Surface treatments such as galvanization, electroplating, and chemical conversion coatings significantly enhance zinc's corrosion resistance by forming protective barriers against environmental factors. These treatments maintain zinc's excellent electrical conductivity, crucial in applications like grounding systems and battery components. Optimizing the balance between corrosion protection and conductivity through advanced surface engineering ensures extended lifespan and consistent performance in zinc-based applications.

Industry-Specific Uses: Corrosion Resistance or Conductivity?

Zinc's exceptional corrosion resistance makes it a preferred choice for protective coatings in automotive, construction, and marine industries, where durability against rust and environmental damage is crucial. In contrast, its moderate electrical conductivity limits its direct use in electrical components but serves well in alloying processes to enhance corrosion resistance without significantly compromising conductivity. Industries prioritize zinc's corrosion resistance for structural applications, while conductivity is optimized through zinc alloys in specialized electrical and electronic uses.

Choosing Zinc for Optimal Performance: Decision Criteria

Zinc offers an exceptional balance between corrosion resistance and conductivity, making it ideal for applications requiring durability and efficient electrical performance. Selecting zinc for optimal performance involves evaluating environmental exposure, electrical demands, and mechanical stress to ensure long-term reliability. Prioritize zinc alloys with tailored purity levels and surface treatments to enhance corrosion protection while maintaining adequate conductivity for specific industrial uses.

Corrosion Resistance vs Conductivity (Zinc Applications) Infographic

materialdif.com

materialdif.com