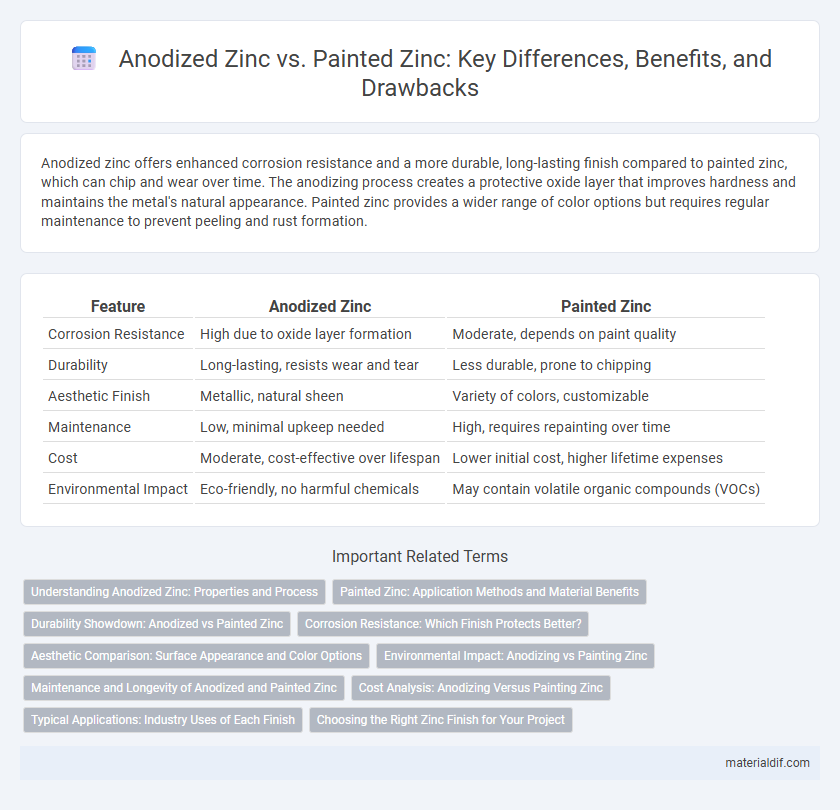

Anodized zinc offers enhanced corrosion resistance and a more durable, long-lasting finish compared to painted zinc, which can chip and wear over time. The anodizing process creates a protective oxide layer that improves hardness and maintains the metal's natural appearance. Painted zinc provides a wider range of color options but requires regular maintenance to prevent peeling and rust formation.

Table of Comparison

| Feature | Anodized Zinc | Painted Zinc |

|---|---|---|

| Corrosion Resistance | High due to oxide layer formation | Moderate, depends on paint quality |

| Durability | Long-lasting, resists wear and tear | Less durable, prone to chipping |

| Aesthetic Finish | Metallic, natural sheen | Variety of colors, customizable |

| Maintenance | Low, minimal upkeep needed | High, requires repainting over time |

| Cost | Moderate, cost-effective over lifespan | Lower initial cost, higher lifetime expenses |

| Environmental Impact | Eco-friendly, no harmful chemicals | May contain volatile organic compounds (VOCs) |

Understanding Anodized Zinc: Properties and Process

Anodized zinc undergoes an electrochemical process that enhances corrosion resistance by forming a dense oxide layer, improving durability and surface hardness. This treatment provides better adhesion for subsequent coatings, unlike painted zinc, which only offers a protective barrier that may degrade over time. Understanding anodized zinc's properties is crucial for applications requiring long-lasting protection and improved aesthetic finish in industrial and architectural uses.

Painted Zinc: Application Methods and Material Benefits

Painted zinc offers versatile application methods such as spray, dip, and brush coating, enabling uniform coverage and enhanced corrosion resistance. The material benefits include improved aesthetic appeal, UV stability, and added protection against harsh environmental factors compared to bare or anodized zinc. This makes painted zinc ideal for architectural components, outdoor fixtures, and automotive parts requiring long-lasting durability and color retention.

Durability Showdown: Anodized vs Painted Zinc

Anodized zinc offers superior durability by forming a protective oxide layer that resists corrosion and wear, extending the lifespan of the metal significantly compared to painted zinc. Painted zinc provides an initial barrier against environmental factors but is prone to chipping and peeling, leading to compromised protection over time. In high-exposure environments, anodized zinc consistently outperforms painted zinc in maintaining structural integrity and aesthetic quality.

Corrosion Resistance: Which Finish Protects Better?

Anodized zinc offers superior corrosion resistance by forming a dense, protective oxide layer that inhibits rust and environmental damage, extending the lifespan of metal surfaces. Painted zinc provides a barrier coating but can chip or wear away over time, exposing the base metal to corrosion risks. Therefore, anodized zinc generally protects better in harsh or outdoor conditions due to its durable, integral finish.

Aesthetic Comparison: Surface Appearance and Color Options

Anodized zinc offers a smooth, metallic finish with a subtle sheen that enhances its natural silver-gray color, providing a modern and durable aesthetic. Painted zinc allows for a broader range of vibrant color options and finishes, including matte, gloss, and textured surfaces, enabling greater customization to match design preferences. While anodized zinc maintains a consistent, corrosion-resistant appearance over time, painted zinc may require periodic maintenance to preserve its color and finish integrity.

Environmental Impact: Anodizing vs Painting Zinc

Anodized zinc offers a more environmentally friendly alternative to painted zinc by eliminating the need for harmful solvents and volatile organic compounds (VOCs) commonly released during painting processes. The anodizing process enhances corrosion resistance through a controlled oxide layer without generating hazardous waste, reducing its ecological footprint. Painted zinc often requires frequent recoating, increasing resource consumption and environmental impact over the product lifespan.

Maintenance and Longevity of Anodized and Painted Zinc

Anodized zinc offers superior corrosion resistance and durability due to its protective oxide layer, resulting in lower maintenance requirements and extended lifespan compared to painted zinc. Painted zinc requires periodic repainting and touch-ups to prevent paint degradation and underlying metal corrosion from moisture exposure. The enhanced longevity of anodized zinc makes it a cost-effective option for applications demanding long-term structural integrity with minimal upkeep.

Cost Analysis: Anodizing Versus Painting Zinc

Anodized zinc offers increased surface durability and corrosion resistance at a higher upfront cost compared to painted zinc, which requires frequent maintenance and repainting expenses over time. The anodizing process involves electrochemical treatment that produces a protective oxide layer, reducing long-term replacement costs despite initial investment. Painted zinc, while initially less expensive, incurs additional costs through recurrent recoating and potential corrosion damage, making anodized zinc a more cost-effective solution for long-term applications.

Typical Applications: Industry Uses of Each Finish

Anodized zinc is commonly used in aerospace, automotive, and electronic industries due to its enhanced corrosion resistance and durable, wear-resistant surface ideal for harsh environments. Painted zinc finds typical applications in construction and architectural projects where aesthetic appeal and additional protective coating are required for structural components and metal fixtures. Both finishes are essential in industrial settings, with anodized zinc prioritizing functional longevity and painted zinc offering versatile color options and surface protection.

Choosing the Right Zinc Finish for Your Project

Anodized zinc offers enhanced corrosion resistance and a durable, non-porous surface suitable for outdoor and industrial applications, while painted zinc provides versatile color options and aesthetic customization but may require more maintenance over time. Selecting the right zinc finish depends on exposure conditions, desired appearance, and longevity requirements, with anodizing preferred for high-durability needs and painting ideal for decorative purposes. Understanding the environmental factors and project specifications ensures optimal performance and protection from rust and wear.

Anodized Zinc vs Painted Zinc Infographic

materialdif.com

materialdif.com