Zinc flake coating offers superior corrosion resistance and is applied as a thin, even layer without the need for electrolysis, making it ideal for complex geometries in automotive and industrial parts. Zinc electroplating involves depositing a thicker zinc layer through an electrical process, providing effective protection but often requiring post-treatment for enhanced durability. Choosing between zinc flake coating and zinc electroplating depends on factors such as environmental exposure, mechanical requirements, and cost efficiency.

Table of Comparison

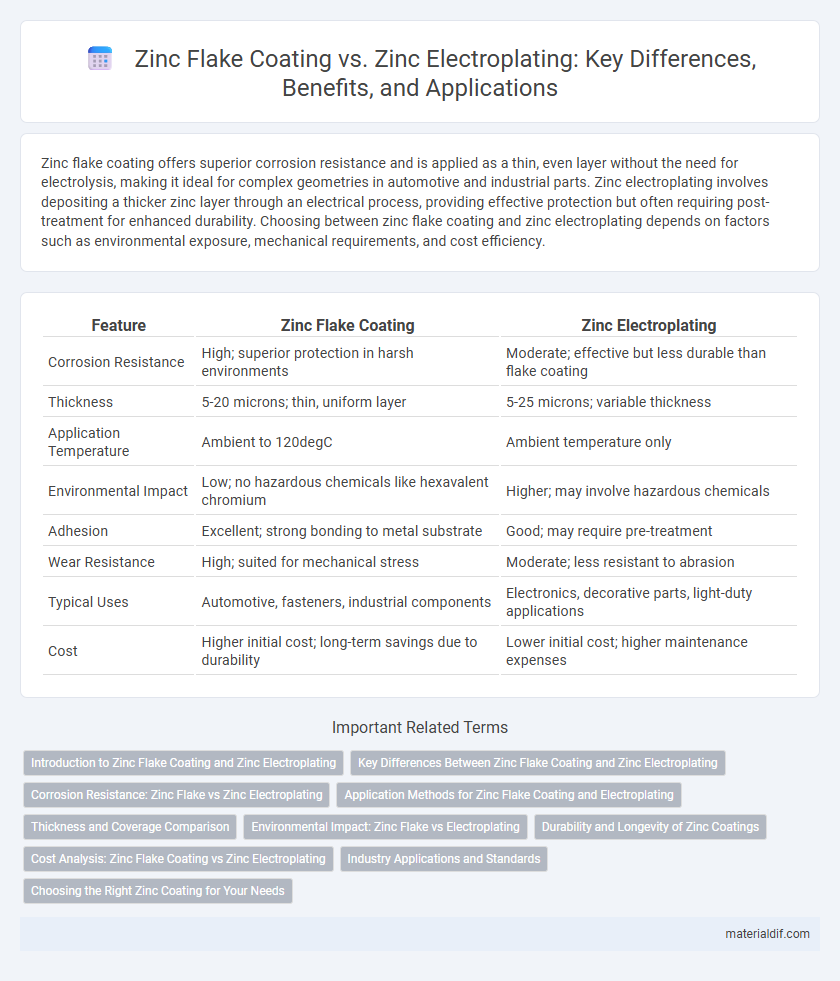

| Feature | Zinc Flake Coating | Zinc Electroplating |

|---|---|---|

| Corrosion Resistance | High; superior protection in harsh environments | Moderate; effective but less durable than flake coating |

| Thickness | 5-20 microns; thin, uniform layer | 5-25 microns; variable thickness |

| Application Temperature | Ambient to 120degC | Ambient temperature only |

| Environmental Impact | Low; no hazardous chemicals like hexavalent chromium | Higher; may involve hazardous chemicals |

| Adhesion | Excellent; strong bonding to metal substrate | Good; may require pre-treatment |

| Wear Resistance | High; suited for mechanical stress | Moderate; less resistant to abrasion |

| Typical Uses | Automotive, fasteners, industrial components | Electronics, decorative parts, light-duty applications |

| Cost | Higher initial cost; long-term savings due to durability | Lower initial cost; higher maintenance expenses |

Introduction to Zinc Flake Coating and Zinc Electroplating

Zinc flake coating offers a thin, uniform layer of zinc alloy that delivers excellent corrosion resistance without the need for electrical current, using a combination of zinc and aluminum flakes bonded with resin. Zinc electroplating involves depositing a layer of pure zinc onto a metal substrate through an electrolytic process, providing effective protection against rust while enhancing electrical conductivity. Both methods are widely used in automotive, construction, and industrial applications for protecting steel components from corrosion.

Key Differences Between Zinc Flake Coating and Zinc Electroplating

Zinc flake coating offers superior corrosion resistance and environmental benefits compared to zinc electroplating, which relies on electrochemical deposition and often involves hazardous chemicals. Unlike zinc electroplating, zinc flake coating creates a non-electrolytic barrier, providing consistent uniform coverage on complex geometries without hydrogen embrittlement risk. The key difference lies in application methods and performance, with zinc flake coatings preferred for heavy-duty industrial use due to their durability and eco-friendliness.

Corrosion Resistance: Zinc Flake vs Zinc Electroplating

Zinc flake coating offers superior corrosion resistance compared to zinc electroplating due to its multi-layered structure and the absence of hydrogen embrittlement risks, making it ideal for high-performance industrial applications. Zinc electroplating provides a thinner protective layer, which can deteriorate more quickly under harsh environmental conditions, reducing long-term durability. The enhanced barrier protection and sacrificial corrosion mechanism of zinc flake coatings extend the lifespan of metal components significantly in aggressive environments.

Application Methods for Zinc Flake Coating and Electroplating

Zinc flake coating is applied through a cold, non-electrolytic process involving spray or dip methods followed by curing at moderate temperatures, which provides uniform coverage and excellent corrosion resistance without hydrogen embrittlement. Zinc electroplating relies on an electrolytic process where components serve as cathodes in an electrolyte bath, depositing a zinc layer through controlled electrical current, suitable for precise thickness control but prone to hydrogen uptake. Both methods are widely used in automotive and industrial applications, with zinc flake coating favored for complex geometries and high-performance requirements, while electroplating suits simpler shapes needing economical zinc protection.

Thickness and Coverage Comparison

Zinc flake coating typically offers a uniform thickness ranging from 5 to 15 microns, providing comprehensive surface coverage including thread roots and inner holes, while zinc electroplating usually deposits a thinner layer of 3 to 10 microns with limited coverage on complex geometries. The enhanced thickness and consistent coverage of zinc flake coatings result in superior corrosion resistance compared to traditional zinc electroplating. This difference makes zinc flake coatings more suitable for applications requiring durable, complete protection of intricate metal parts.

Environmental Impact: Zinc Flake vs Electroplating

Zinc flake coating offers a more environmentally friendly alternative to zinc electroplating by eliminating the use of hazardous hexavalent chromium and reducing toxic waste generation. This method also consumes less energy and produces fewer harmful emissions compared to traditional electroplating processes. As a result, zinc flake coating aligns better with modern sustainability standards and strict environmental regulations.

Durability and Longevity of Zinc Coatings

Zinc flake coating offers superior durability and corrosion resistance compared to traditional zinc electroplating, making it ideal for harsh environments and long-term applications. The multilayer structure of zinc flake coatings ensures extended longevity by providing enhanced protection against rust, even after mechanical damage. Zinc electroplating, while effective for moderate protection, typically has a thinner coating that wears faster under abrasive conditions, reducing its lifespan.

Cost Analysis: Zinc Flake Coating vs Zinc Electroplating

Zinc flake coating typically incurs higher initial application costs compared to zinc electroplating, but offers long-term savings due to superior corrosion resistance and reduced maintenance requirements. Zinc electroplating provides a cost-effective solution for projects with lower exposure to harsh environments, benefiting from faster application processes and less expensive chemicals. Selecting between the two methods depends on the balance between upfront investment and lifecycle cost efficiency in preventing metal corrosion.

Industry Applications and Standards

Zinc flake coating is preferred in automotive and aerospace industries for its superior corrosion resistance, meeting strict standards such as ISO 10683 and VDA 233-102, while zinc electroplating remains common in general manufacturing and electronics due to ISO 2081 compliance and cost-effectiveness. The flake coating process provides a non-electrolytic method that avoids hydrogen embrittlement, making it essential for high-strength steel components in construction and heavy machinery. Zinc electroplating often serves applications requiring moderate corrosion protection and electrical conductivity, adhering to ASTM B633 standards in industrial hardware and fasteners.

Choosing the Right Zinc Coating for Your Needs

Zinc flake coating offers superior corrosion resistance and is ideal for applications requiring non-electrolytic deposition, making it suitable for complex geometries and lightweight components. Zinc electroplating provides good conductivity and is cost-effective for large-scale production but may require additional passivation for enhanced durability. Selecting the right zinc coating depends on factors such as environmental exposure, mechanical stress, and regulatory standards specific to your industry.

Zinc Flake Coating vs Zinc Electroplating Infographic

materialdif.com

materialdif.com