Yellow zinc plating offers enhanced corrosion resistance and a distinctive golden hue that improves visual distinction and aesthetic appeal in pet hardware. Clear zinc plating provides a shiny, silver finish that maintains the natural metallic look while also preventing rust and oxidation. Both options create durable, long-lasting protective coatings for zinc pet products, balancing appearance and functionality.

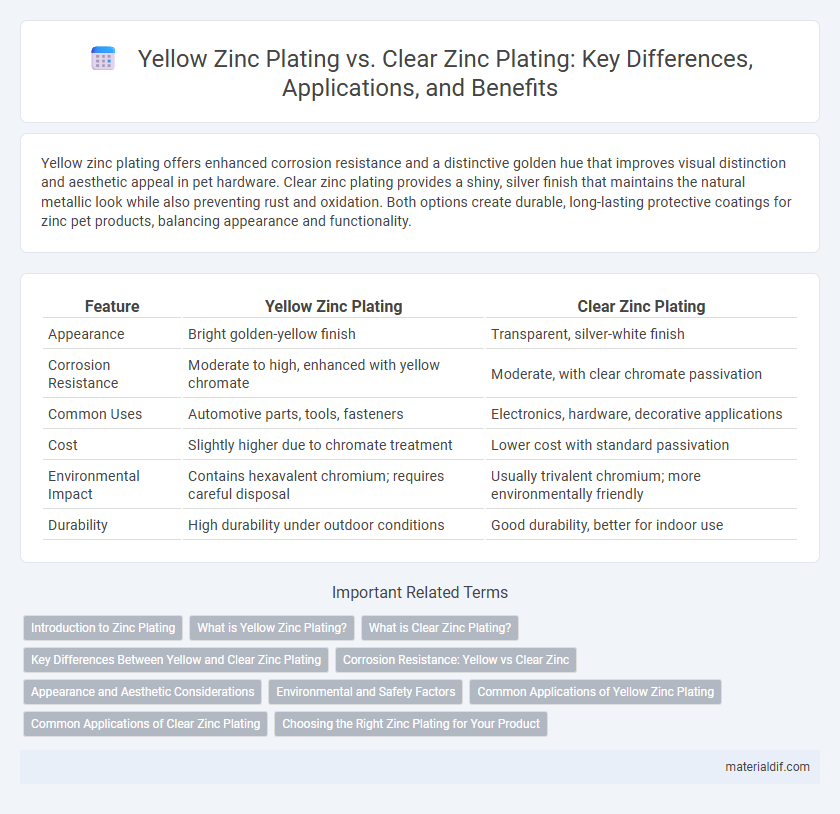

Table of Comparison

| Feature | Yellow Zinc Plating | Clear Zinc Plating |

|---|---|---|

| Appearance | Bright golden-yellow finish | Transparent, silver-white finish |

| Corrosion Resistance | Moderate to high, enhanced with yellow chromate | Moderate, with clear chromate passivation |

| Common Uses | Automotive parts, tools, fasteners | Electronics, hardware, decorative applications |

| Cost | Slightly higher due to chromate treatment | Lower cost with standard passivation |

| Environmental Impact | Contains hexavalent chromium; requires careful disposal | Usually trivalent chromium; more environmentally friendly |

| Durability | High durability under outdoor conditions | Good durability, better for indoor use |

Introduction to Zinc Plating

Yellow zinc plating offers enhanced corrosion resistance through a chromate conversion coating that provides a distinctive yellow-gold finish, making it suitable for automotive and industrial applications. Clear zinc plating delivers a natural, bright metallic appearance while protecting steel substrates from rust and oxidation, commonly used in electronics and hardware manufacturing. Both plating types utilize electrogalvanization to deposit a zinc layer that extends the lifespan of metal components by preventing environmental damage.

What is Yellow Zinc Plating?

Yellow zinc plating is a type of corrosion-resistant coating that applies a yellow chromate conversion layer over a zinc-plated metal surface, providing enhanced durability and a distinctive golden hue. This plating offers superior protection against rust and abrasion compared to clear zinc plating, making it ideal for automotive, hardware, and industrial applications. The yellow chromate finish also improves the visual aesthetics and lubrication properties of the metal parts.

What is Clear Zinc Plating?

Clear zinc plating is a type of corrosion-resistant coating applied to steel and iron to provide a bright, silver-like finish that enhances durability and protection against rust. Unlike yellow zinc plating, which has a yellow or gold tint due to chromate conversion coatings, clear zinc plating maintains a neutral, metallic appearance without altering the base metal's color. This plating method is commonly used in automotive, construction, and hardware industries where aesthetic appeal and corrosion resistance are essential.

Key Differences Between Yellow and Clear Zinc Plating

Yellow zinc plating features a chromate conversion coating that provides enhanced corrosion resistance and a distinctive yellow-gold appearance, while clear zinc plating offers a transparent finish emphasizing the base metal's natural color. Yellow zinc plating typically includes a higher level of chromate treatment, boosting durability in harsh environments compared to the more decorative, corrosion-resistant but less robust clear zinc plating. The choice between yellow and clear zinc plating depends on specific application needs, such as the required corrosion protection level and aesthetic preferences.

Corrosion Resistance: Yellow vs Clear Zinc

Yellow zinc plating offers enhanced corrosion resistance due to the inclusion of yellow chromate conversion coatings, which provide a thicker and more durable protective layer compared to clear zinc plating's transparent chromate finish. Clear zinc plating primarily relies on zinc's natural corrosion resistance but typically provides a thinner barrier, making it less effective in harsh, outdoor environments. Industry data shows yellow zinc plated components resist corrosion up to 720 hours in salt spray tests, whereas clear zinc plating generally withstands around 240 to 480 hours.

Appearance and Aesthetic Considerations

Yellow zinc plating offers a warm, golden hue that enhances the visual appeal of metal parts, making them popular for decorative applications where a vibrant finish is desired. Clear zinc plating provides a bright, silvery appearance that maintains the natural color of the base metal, ideal for achieving a clean and neutral aesthetic. Both finishes improve corrosion resistance while allowing designers to choose between a striking yellow tint or a subtle, clear look based on aesthetic requirements.

Environmental and Safety Factors

Yellow zinc plating contains chromate conversion coatings that can release hexavalent chromium, a toxic substance harmful to both the environment and human health, making disposal and handling more regulated and hazardous. Clear zinc plating uses trivalent chromium or non-chromate coatings, which are less toxic and environmentally safer, reducing risks of soil and water contamination. Both types provide corrosion resistance, but clear zinc plating is preferred for applications prioritizing environmental compliance and worker safety.

Common Applications of Yellow Zinc Plating

Yellow zinc plating is commonly applied in automotive components, hardware, and fasteners to provide enhanced corrosion resistance and a distinctive gold appearance. It is preferred in construction and electrical industries where improved durability and visibility are essential. The chromate conversion coating in yellow zinc plating offers superior protection against rust compared to clear zinc plating.

Common Applications of Clear Zinc Plating

Clear zinc plating is widely used in automotive parts, fasteners, and electrical components due to its corrosion resistance and ability to maintain the substrate's original color. Common applications include screws, bolts, and brackets where aesthetic consistency and moderate protection from rust are essential. This plating type is preferred in industries requiring a clean, bright finish without the yellow tint associated with yellow zinc plating.

Choosing the Right Zinc Plating for Your Product

Yellow zinc plating offers enhanced corrosion resistance due to its chromate conversion coating, making it ideal for outdoor or high-humidity environments. Clear zinc plating provides a bright, natural finish suited for aesthetic applications where moderate protection is sufficient. Selecting the right zinc plating depends on balancing durability requirements with desired appearance and environmental exposure.

Yellow zinc plating vs Clear zinc plating Infographic

materialdif.com

materialdif.com