Zinc sheet offers a larger surface area and is ideal for extensive roofing and cladding projects, while zinc strip provides thinner, more flexible options suitable for intricate detailing and flashing. Both materials share corrosion resistance and durability but differ in thickness and application scale. Choosing between zinc sheet and zinc strip depends on project requirements, with sheets best for broad coverage and strips for precision work.

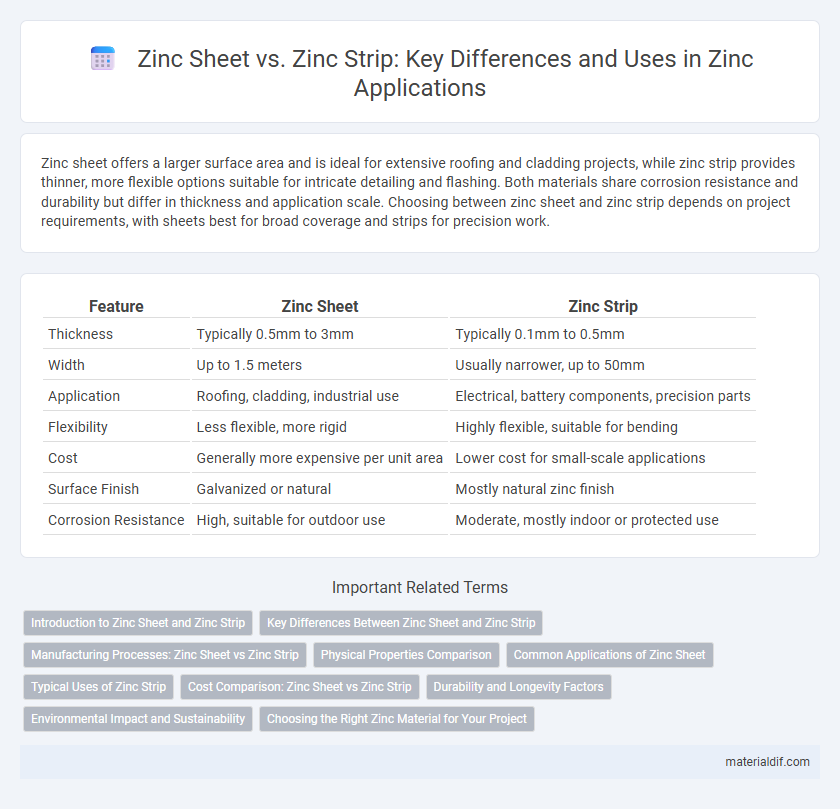

Table of Comparison

| Feature | Zinc Sheet | Zinc Strip |

|---|---|---|

| Thickness | Typically 0.5mm to 3mm | Typically 0.1mm to 0.5mm |

| Width | Up to 1.5 meters | Usually narrower, up to 50mm |

| Application | Roofing, cladding, industrial use | Electrical, battery components, precision parts |

| Flexibility | Less flexible, more rigid | Highly flexible, suitable for bending |

| Cost | Generally more expensive per unit area | Lower cost for small-scale applications |

| Surface Finish | Galvanized or natural | Mostly natural zinc finish |

| Corrosion Resistance | High, suitable for outdoor use | Moderate, mostly indoor or protected use |

Introduction to Zinc Sheet and Zinc Strip

Zinc sheets and zinc strips are versatile materials widely used in construction, manufacturing, and metalworking due to their corrosion resistance and durability. Zinc sheets are flat, thin metal plates typically ranging from 0.2 mm to 6 mm in thickness, offering excellent flexibility and ease of shaping for roofing, cladding, and decorative applications. Zinc strips are narrower and thinner than sheets, often used for precise tasks like electrical grounding, soldering, and small-scale fabrication where detailed metalwork is required.

Key Differences Between Zinc Sheet and Zinc Strip

Zinc sheets are typically thicker and larger, making them ideal for structural applications like roofing, cladding, and flashing, while zinc strips are thinner and narrower, often used for detailed or smaller-scale metalwork such as sealing and decorative trims. The sheet form offers enhanced durability and strength, whereas strips provide greater flexibility and precision in bending or cutting tasks. Understanding these differences helps in selecting the appropriate zinc product based on the project's scale, strength requirements, and application complexity.

Manufacturing Processes: Zinc Sheet vs Zinc Strip

Zinc sheets are typically produced through hot rolling or cold rolling processes that involve compressing zinc slabs into flat, broad panels, ensuring uniform thickness and surface smoothness for applications like roofing and cladding. Zinc strips, on the other hand, are manufactured by further processing zinc sheets through slitting and precision rolling, resulting in narrower, thinner widths suitable for intricate uses such as electronics and metal joining. The manufacturing of zinc strips demands tighter dimensional tolerances and enhanced surface finishes compared to zinc sheets, reflecting their specialized functional requirements.

Physical Properties Comparison

Zinc sheets exhibit greater thickness, typically ranging from 0.2 to 6 mm, providing enhanced rigidity and structural support compared to zinc strips, which are thinner and commonly measure between 0.1 to 0.5 mm. Both materials possess similar density around 7.14 g/cm3 and melting point near 419.5degC, but zinc sheets offer superior tensile strength due to their larger cross-sectional area. Flexibility is higher in zinc strips, making them more suitable for applications requiring bending or shaping without compromising corrosion resistance.

Common Applications of Zinc Sheet

Zinc sheets are widely used in roofing, cladding, and gutter systems due to their durability and corrosion resistance, making them ideal for architectural applications. They are also favored in the production of flashings, ventilation ducts, and protective coverings in construction and industrial settings. Zinc strips are more commonly used in small-scale applications like battery manufacturing and metal joining processes.

Typical Uses of Zinc Strip

Zinc strips are commonly used in electrochemical applications such as galvanic cells, zinc-air batteries, and corrosion testing due to their high purity and flexible form. They serve effectively in laboratory experiments and metal plating processes where precise control over zinc surface area is critical. Unlike zinc sheets, strips provide easier handling and better adaptability for small-scale industrial uses and specialized scientific setups.

Cost Comparison: Zinc Sheet vs Zinc Strip

Zinc sheets generally offer a lower cost per square foot compared to zinc strips due to their larger size and reduced manufacturing complexity. Zinc strips, being narrower and often produced in smaller quantities, typically incur higher production and handling costs, leading to a higher price point. For applications requiring extensive coverage, zinc sheets provide a more cost-effective solution than zinc strips.

Durability and Longevity Factors

Zinc sheets generally offer superior durability and longevity due to their thicker gauge, which provides enhanced resistance to corrosion and mechanical wear compared to zinc strips. Zinc strips, being thinner, are more prone to deformation and may require more frequent replacement in high-stress or outdoor environments. The longevity of zinc sheets is further extended by their ability to develop a protective patina over time, significantly reducing maintenance costs.

Environmental Impact and Sustainability

Zinc sheets and zinc strips differ in environmental impact due to their manufacturing processes and application efficiency, with sheets typically requiring more material and energy input compared to thinner, flexible strips. Zinc strips offer improved sustainability through reduced raw material consumption and lower transportation emissions, contributing to less environmental footprint in construction and industrial uses. Both forms benefit from zinc's natural corrosion resistance and recyclability, but strips enable more precise usage, minimizing waste and promoting eco-friendly practices.

Choosing the Right Zinc Material for Your Project

Zinc sheets offer larger surface coverage ideal for roofing, cladding, and complex architectural applications, while zinc strips provide precise, narrow widths suited for detailed metalwork, flashing, and edging tasks. Selecting the right zinc material depends on project scale, required durability, and specific design needs, with sheets excelling in broad, flat coverage and strips favored for flexibility and intricate installations. Both materials deliver excellent corrosion resistance and malleability, ensuring long-lasting performance in diverse construction and manufacturing applications.

Zinc Sheet vs Zinc Strip Infographic

materialdif.com

materialdif.com