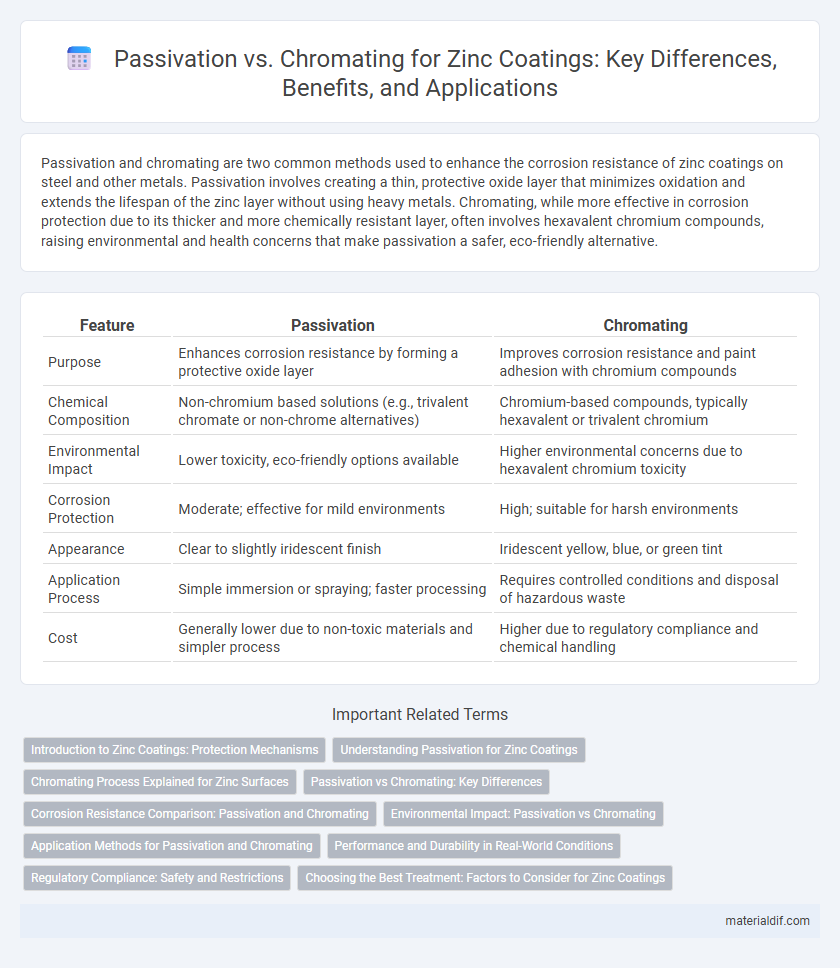

Passivation and chromating are two common methods used to enhance the corrosion resistance of zinc coatings on steel and other metals. Passivation involves creating a thin, protective oxide layer that minimizes oxidation and extends the lifespan of the zinc layer without using heavy metals. Chromating, while more effective in corrosion protection due to its thicker and more chemically resistant layer, often involves hexavalent chromium compounds, raising environmental and health concerns that make passivation a safer, eco-friendly alternative.

Table of Comparison

| Feature | Passivation | Chromating |

|---|---|---|

| Purpose | Enhances corrosion resistance by forming a protective oxide layer | Improves corrosion resistance and paint adhesion with chromium compounds |

| Chemical Composition | Non-chromium based solutions (e.g., trivalent chromate or non-chrome alternatives) | Chromium-based compounds, typically hexavalent or trivalent chromium |

| Environmental Impact | Lower toxicity, eco-friendly options available | Higher environmental concerns due to hexavalent chromium toxicity |

| Corrosion Protection | Moderate; effective for mild environments | High; suitable for harsh environments |

| Appearance | Clear to slightly iridescent finish | Iridescent yellow, blue, or green tint |

| Application Process | Simple immersion or spraying; faster processing | Requires controlled conditions and disposal of hazardous waste |

| Cost | Generally lower due to non-toxic materials and simpler process | Higher due to regulatory compliance and chemical handling |

Introduction to Zinc Coatings: Protection Mechanisms

Zinc coatings protect steel primarily through galvanic action and barrier effects, with passivation and chromating serving as crucial post-treatment methods to enhance corrosion resistance. Passivation creates a thin, transparent oxide layer that inhibits surface reactivity, while chromating forms a complex, corrosion-resistant film rich in chromium compounds that significantly improves durability. The choice between passivation and chromating depends on environmental exposure, regulatory constraints, and desired longevity of the zinc-coated substrate.

Understanding Passivation for Zinc Coatings

Passivation for zinc coatings involves creating a protective oxide layer that enhances corrosion resistance by preventing further metal oxidation. This chemical treatment typically uses solutions containing chromium-free compounds, promoting environmental safety compared to traditional chromating processes. Understanding passivation helps optimize zinc coating durability by improving adhesion and reducing surface defects while minimizing toxic chromium usage.

Chromating Process Explained for Zinc Surfaces

Chromating process for zinc surfaces involves applying a thin layer of chromium-based chemical conversion coating that enhances corrosion resistance and paint adhesion. This method creates a protective oxide film that passivates the zinc, preventing oxidation and extending the lifespan of zinc-coated materials. Compared to simple passivation, chromating offers superior durability and environmental resistance for zinc coatings.

Passivation vs Chromating: Key Differences

Passivation and chromating are two primary methods used to enhance the corrosion resistance of zinc coatings, with passivation involving the formation of a thin, protective oxide layer that inhibits oxidation, while chromating applies a chromium-based conversion coating that provides greater durability and long-term protection. Passivation typically yields environmentally friendly results with less toxic byproducts, whereas chromating offers superior resistance to chemical attack and improved adhesion for subsequent paints and coatings. The choice between passivation and chromating depends on factors such as environmental regulations, desired corrosion resistance, and application requirements for zinc-coated surfaces.

Corrosion Resistance Comparison: Passivation and Chromating

Passivation and chromating are essential methods for enhancing corrosion resistance in zinc coatings, with chromating generally providing superior long-term protection due to its formation of a denser, more stable conversion layer. Passivation, typically involving treatments with nitric or other acids, creates a thin, protective oxide film that improves corrosion resistance but is less durable in harsh environments compared to chromate coatings. Chromate treatments also offer better resistance against humidity and salt spray, making them preferred for applications requiring prolonged exposure to corrosive conditions.

Environmental Impact: Passivation vs Chromating

Passivation of zinc coatings significantly reduces environmental hazards by avoiding hexavalent chromium compounds, which are highly toxic and carcinogenic. Chromating processes release hazardous chromium(VI) electrolytes, posing severe risks to aquatic life and complicating waste treatment protocols. Zinc passivation offers a safer, more eco-friendly alternative with lower regulatory restrictions and improved worker safety.

Application Methods for Passivation and Chromating

Passivation of zinc coatings commonly involves immersion or spraying techniques using chromate-free solutions containing sodium molybdate or zirconium compounds to form a protective oxide layer. Chromating typically employs immersion in hexavalent or trivalent chromium-based baths, enabling a conversion coating that enhances corrosion resistance and paint adhesion. Industrial standards such as ASTM B633 guide the application parameters, including bath concentration, temperature, and exposure time, ensuring consistent and durable zinc surface treatments.

Performance and Durability in Real-World Conditions

Passivation of zinc coatings enhances corrosion resistance by forming a thin, stable oxide layer that improves durability in mild environments, while chromating creates a conversion coating that offers superior protection against aggressive weathering and chemical exposure. Chromated zinc surfaces exhibit better adhesion for subsequent painting and higher resistance to salt spray, extending service life in marine and industrial conditions significantly compared to passivated coatings. Performance differences are notable under real-world conditions where chromating reduces white rust formation and maintains structural integrity longer than typical passivation treatments.

Regulatory Compliance: Safety and Restrictions

Passivation of zinc coatings uses non-toxic, chromium-free solutions that align with strict environmental regulations, reducing hazardous waste and limiting worker exposure to harmful chemicals. Chromating processes, often involving hexavalent chromium, face increasing legal restrictions due to its carcinogenic properties and high toxicity, prompting regulatory bodies like REACH and RoHS to mandate safer alternatives. Companies must ensure compliance by selecting passivation methods to meet safety standards and avoid penalties linked to restricted chromate usage.

Choosing the Best Treatment: Factors to Consider for Zinc Coatings

Selecting the best treatment for zinc coatings involves comparing passivation and chromating based on corrosion resistance, environmental impact, and application compatibility. Passivation enhances zinc's corrosion protection by forming a stable oxide layer, suitable for indoor environments and less toxic applications. Chromating offers superior corrosion resistance and paint adhesion for outdoor or harsh conditions but involves hexavalent chromium compounds, raising environmental and safety concerns that influence regulatory compliance.

Passivation vs Chromating (for zinc coatings) Infographic

materialdif.com

materialdif.com