Zinc rods offer a uniform shape and are ideal for precise casting and electroplating applications in the pet industry, while zinc ingots provide bulk material suitable for large-scale melting and alloy production. Zinc rods typically have higher purity and better surface finish, enhancing corrosion resistance and electrical conductivity compared to ingots. Choosing between zinc rods and zinc ingots depends on the specific manufacturing process requirements and the desired mechanical properties in pet-related components.

Table of Comparison

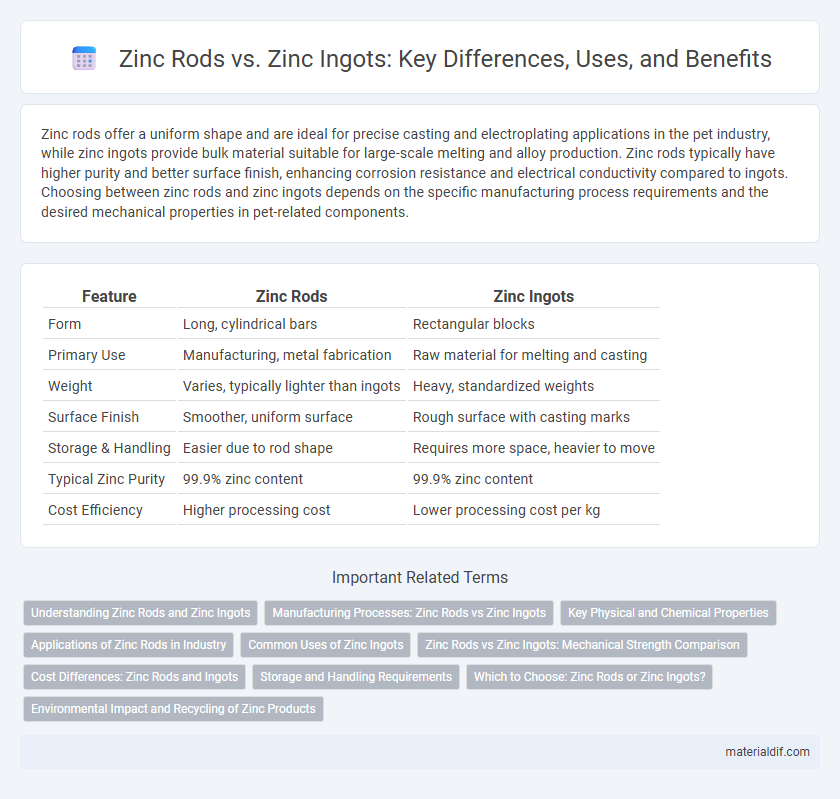

| Feature | Zinc Rods | Zinc Ingots |

|---|---|---|

| Form | Long, cylindrical bars | Rectangular blocks |

| Primary Use | Manufacturing, metal fabrication | Raw material for melting and casting |

| Weight | Varies, typically lighter than ingots | Heavy, standardized weights |

| Surface Finish | Smoother, uniform surface | Rough surface with casting marks |

| Storage & Handling | Easier due to rod shape | Requires more space, heavier to move |

| Typical Zinc Purity | 99.9% zinc content | 99.9% zinc content |

| Cost Efficiency | Higher processing cost | Lower processing cost per kg |

Understanding Zinc Rods and Zinc Ingots

Zinc rods and zinc ingots serve distinct purposes in industrial applications, with rods typically used in galvanization and manufacturing processes due to their elongated, solid form, offering ease in handling and machining. Zinc ingots, characterized by their block or bar shape, are primarily utilized for storage and transportation, enabling efficient melting and alloy production in foundries. Both forms maintain high purity levels, crucial for ensuring corrosion resistance and material performance in construction and automotive industries.

Manufacturing Processes: Zinc Rods vs Zinc Ingots

Zinc rods are typically produced through continuous casting or hot rolling, where molten zinc is solidified into cylindrical shapes with precise dimensions, ensuring uniform mechanical properties and surface finish. Zinc ingots, on the other hand, are manufactured by casting molten zinc into rectangular molds and are primarily used as raw material for further processing or alloy production. The manufacturing process for zinc rods demands tighter control over cooling rates and finishing to meet industrial standards, whereas zinc ingots focus on bulk production efficiency.

Key Physical and Chemical Properties

Zinc rods exhibit high tensile strength and uniform composition, making them ideal for manufacturing and galvanizing applications, while zinc ingots provide a bulk supply with variable shapes suitable for alloy production and casting. Both forms possess a melting point of approximately 419.5degC and demonstrate excellent corrosion resistance, but rods offer superior mechanical stability compared to the more malleable ingots. Chemically, zinc in both rods and ingots maintains strong resistance to oxidation and reactiveness with acids, ensuring durability in industrial processes.

Applications of Zinc Rods in Industry

Zinc rods are extensively used in industrial applications such as galvanizing steel to prevent corrosion, manufacturing batteries, and producing brass alloys due to their high purity and uniformity. Their structural form allows for efficient melting and alloying processes in automotive, construction, and electrical industries. Unlike zinc ingots, rods provide convenient handling and precise dosing in continuous casting and electroplating operations.

Common Uses of Zinc Ingots

Zinc ingots are primarily used in industrial processes such as galvanization, where they protect steel from corrosion by forming a durable zinc coating. They serve as a raw material in die-casting for automotive and machinery components due to zinc's excellent castability and strength. Zinc ingots are also essential in the production of alloys like brass and bronze, enhancing durability and resistance in construction and manufacturing applications.

Zinc Rods vs Zinc Ingots: Mechanical Strength Comparison

Zinc rods exhibit higher mechanical strength compared to zinc ingots due to their refined grain structure achieved through extrusion processes. The denser and more uniform microstructure in zinc rods enhances tensile strength and resistance to deformation under stress. In contrast, zinc ingots, with their coarse grain size and cast nature, have lower mechanical strength and are primarily used as raw material for further processing.

Cost Differences: Zinc Rods and Ingots

Zinc rods generally have higher manufacturing costs compared to zinc ingots due to the additional processing required to form the rod shape and maintain precise dimensions. Zinc ingots are produced via straightforward smelting and casting processes, making them more cost-effective for bulk procurement. Price variations also depend on purity levels and market demand, with rods often commanding premiums in applications needing specific mechanical properties.

Storage and Handling Requirements

Zinc rods require careful storage in dry, well-ventilated areas to prevent oxidation and corrosion, while zinc ingots benefit from similar conditions but offer easier stacking and transport due to their uniform shape. Both forms should be kept away from moisture and acids to maintain integrity during handling. Proper use of protective gloves and equipment is essential to avoid contamination and ensure safe material handling.

Which to Choose: Zinc Rods or Zinc Ingots?

Zinc rods offer precise alloying control and are ideal for applications requiring uniform melting and consistent composition, making them suitable for manufacturing and industrial processes. Zinc ingots provide bulk material for large-scale melting and casting, favored in foundries and smelting operations due to their ease of storage and transport. Choosing between zinc rods and ingots depends on production needs, with rods preferred for controlled alloying and ingots for volume efficiency.

Environmental Impact and Recycling of Zinc Products

Zinc rods and zinc ingots differ notably in environmental impact and recyclability, with zinc ingots generally offering higher efficiency in recycling processes due to their standardized form and purity, which simplifies melting and reprocessing. Zinc rods, often utilized in galvanization and construction, may contain coatings or impurities that complicate recycling and can lead to higher emissions during processing. Sustainable management of zinc products focuses on maximizing recycling rates of ingots while improving sorting techniques for rods to reduce resource consumption and environmental footprint.

Zinc Rods vs Zinc Ingots Infographic

materialdif.com

materialdif.com