Zinc plating involves electrochemically applying a thin layer of zinc onto metal surfaces, offering superior corrosion resistance and a smooth, uniform finish ideal for precision components. Zinc spraying, also known as metallizing, projects molten zinc onto substrates, creating a thicker, more rugged coating suitable for large structures and repair work. Both methods protect against rust, but zinc plating provides enhanced aesthetic appeal while zinc spraying excels in durability and coverage on irregular surfaces.

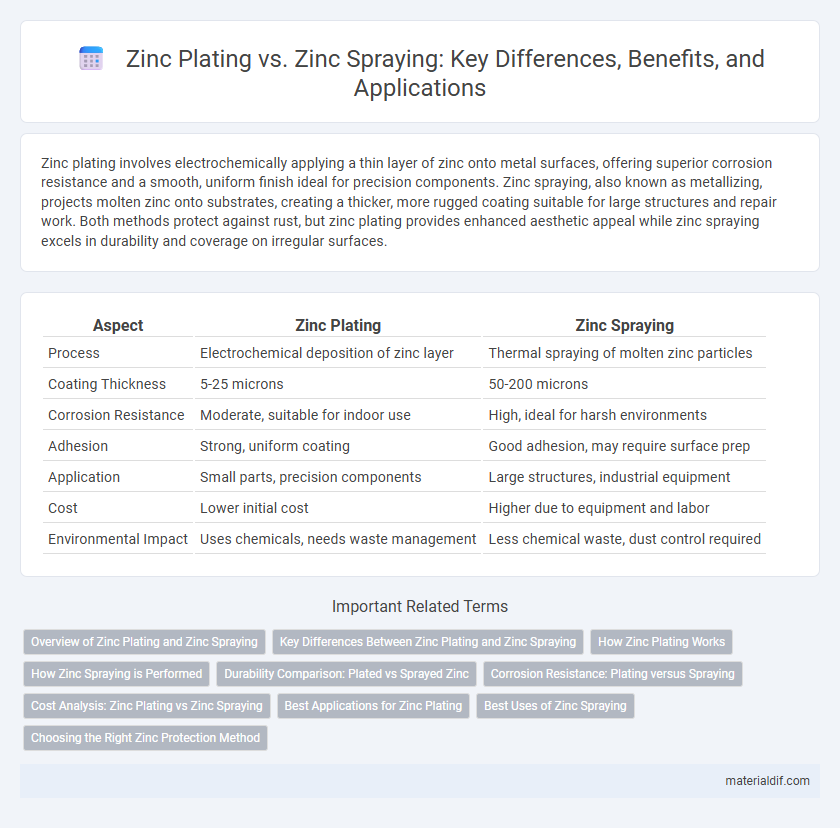

Table of Comparison

| Aspect | Zinc Plating | Zinc Spraying |

|---|---|---|

| Process | Electrochemical deposition of zinc layer | Thermal spraying of molten zinc particles |

| Coating Thickness | 5-25 microns | 50-200 microns |

| Corrosion Resistance | Moderate, suitable for indoor use | High, ideal for harsh environments |

| Adhesion | Strong, uniform coating | Good adhesion, may require surface prep |

| Application | Small parts, precision components | Large structures, industrial equipment |

| Cost | Lower initial cost | Higher due to equipment and labor |

| Environmental Impact | Uses chemicals, needs waste management | Less chemical waste, dust control required |

Overview of Zinc Plating and Zinc Spraying

Zinc plating involves electrochemically depositing a thin layer of zinc onto a metal surface to enhance corrosion resistance and improve appearance. Zinc spraying, also known as metallizing, applies molten or electrically charged zinc particles onto a substrate, creating a thicker, more durable coating ideal for heavy-duty protection. Both methods provide effective zinc coatings but differ in application techniques and coating thickness suitable for various industrial needs.

Key Differences Between Zinc Plating and Zinc Spraying

Zinc plating involves electroplating a thin layer of zinc onto a metal surface for corrosion protection and improved appearance, whereas zinc spraying applies molten zinc particles through thermal spraying to create a thicker, more durable coating. Zinc plating delivers a smooth, uniform finish ideal for precision parts but offers less corrosion resistance under harsh conditions compared to zinc spraying. Zinc spraying provides better adhesion on large or irregular surfaces and superior protection in marine or industrial environments due to its thicker zinc layer and enhanced sacrificial anode effect.

How Zinc Plating Works

Zinc plating works by electrochemically depositing a thin layer of zinc onto the surface of a metal object, creating a protective barrier against corrosion. This process involves immersing the metal in a zinc salt solution and applying an electric current, which causes zinc ions to bind uniformly to the substrate. The resulting zinc coating enhances rust resistance and prolongs the lifespan of steel and iron components in industrial applications.

How Zinc Spraying is Performed

Zinc spraying is performed by melting pure zinc wire or zinc powder using a flame or electric arc spray system and then projecting the molten zinc particles onto the prepared metal surface. This process forms a dense, corrosion-resistant coating that adheres well to complex shapes and hard-to-reach areas. The application temperature and spray parameters are controlled to ensure optimal coating thickness and durability.

Durability Comparison: Plated vs Sprayed Zinc

Zinc plating involves depositing a smooth, uniform layer of zinc through electrochemical processes, providing high corrosion resistance but generally thinner coatings typically between 5 to 25 microns. Zinc spraying, or metallizing, applies molten zinc particles mechanically, creating a thicker, rougher coating ranging from 50 to 200 microns, which offers superior abrasion resistance and longer lifespan in harsh environments. Durability comparisons show zinc spraying excels in heavy-duty applications requiring robust protection against wear and corrosion, while zinc plating suits precision components needing consistent surface finish and moderate durability.

Corrosion Resistance: Plating versus Spraying

Zinc plating offers superior corrosion resistance through a uniform and tightly bonded metallic layer that effectively protects steel from oxidation. Zinc spraying creates a thicker, more porous coating that provides sacrificial protection but may require additional sealing for prolonged durability in harsh environments. Both methods enhance corrosion resistance, but zinc plating generally delivers a more consistent and long-lasting barrier against rust.

Cost Analysis: Zinc Plating vs Zinc Spraying

Zinc plating typically involves higher upfront costs due to specialized equipment and waste disposal requirements but offers a uniform, thin protective coating ideal for precision components. Zinc spraying, while generally more cost-effective for large surfaces and repairs, results in thicker, less consistent coatings that may require additional finishing. Analyzing total cost of ownership, zinc plating suits mass production with stringent specifications, whereas zinc spraying lowers expenses in maintenance and large-scale corrosion protection applications.

Best Applications for Zinc Plating

Zinc plating offers superior corrosion resistance and a smoother, more uniform finish, making it ideal for automotive parts, fasteners, and electronic components that require precise dimensional tolerances. Its electrochemical properties provide enhanced protection against rust in high-humidity environments, suitable for both indoor and outdoor applications. Unlike zinc spraying, zinc plating ensures better adhesion and consistent thickness, critical for components exposed to mechanical stress or requiring aesthetic appeal.

Best Uses of Zinc Spraying

Zinc spraying is best used for repairing and protecting large steel structures where uniform coating and corrosion resistance are critical, such as bridges, pipelines, and industrial machinery. It provides a thicker, more flexible layer of zinc compared to zinc plating, making it ideal for surfaces exposed to harsh weather and mechanical wear. This method is preferred in maintenance and retrofit applications where existing coatings are damaged or require reinforcement.

Choosing the Right Zinc Protection Method

Zinc plating offers a uniform, corrosion-resistant coating ideal for small, precision parts requiring aesthetic appeal and durability, while zinc spraying provides a thicker, more flexible layer suitable for large structures and irregular surfaces exposed to harsher environments. Selecting the right zinc protection method depends on factors such as substrate size, environmental exposure, and desired longevity, with zinc plating favored for automotive and electronics components and zinc spraying typically used in industrial and marine applications. Evaluating budget constraints, application complexity, and maintenance requirements ensures optimal corrosion protection and cost-efficiency.

Zinc Plating vs Zinc Spraying Infographic

materialdif.com

materialdif.com