Zamak and Kirksite are popular alloys used in zinc die casting, each offering distinct advantages for pet-related product manufacturing. Zamak, composed mainly of zinc with aluminum, magnesium, and copper, provides excellent corrosion resistance, high strength, and good finish, making it ideal for durable pet accessories and fittings. Kirksite, an alloy primarily of zinc, aluminum, and copper, excels in precise, detailed casting with a smoother surface finish, suitable for intricate pet product components requiring sharp detail and minimal post-processing.

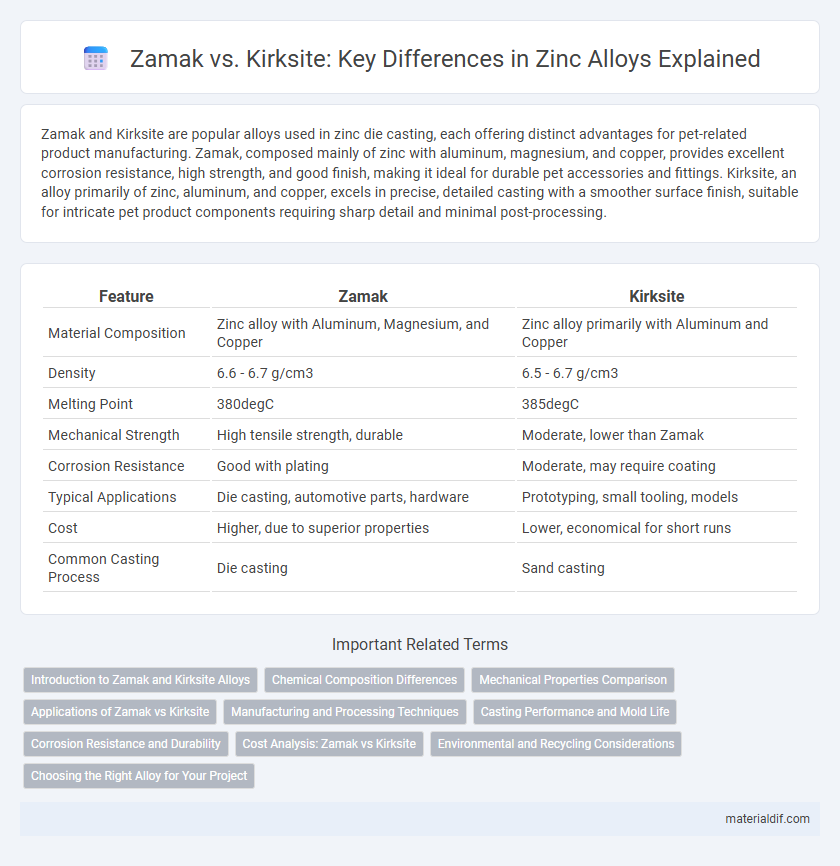

Table of Comparison

| Feature | Zamak | Kirksite |

|---|---|---|

| Material Composition | Zinc alloy with Aluminum, Magnesium, and Copper | Zinc alloy primarily with Aluminum and Copper |

| Density | 6.6 - 6.7 g/cm3 | 6.5 - 6.7 g/cm3 |

| Melting Point | 380degC | 385degC |

| Mechanical Strength | High tensile strength, durable | Moderate, lower than Zamak |

| Corrosion Resistance | Good with plating | Moderate, may require coating |

| Typical Applications | Die casting, automotive parts, hardware | Prototyping, small tooling, models |

| Cost | Higher, due to superior properties | Lower, economical for short runs |

| Common Casting Process | Die casting | Sand casting |

Introduction to Zamak and Kirksite Alloys

Zamak alloys, primarily composed of zinc with aluminum, magnesium, and copper, are known for their excellent strength, ductility, and corrosion resistance, making them ideal for die casting applications. Kirksite, a zinc-aluminum alloy with high thermal conductivity and toughness, is commonly used for gravity casting in precision mold making and prototype development. Both Zamak and Kirksite offer distinct advantages in manufacturing, with Zamak excelling in mass production and Kirksite preferred for intricate, high-quality castings.

Chemical Composition Differences

Zamak alloys mainly consist of zinc with approximately 4% aluminum, 1% copper, and 0.03% magnesium, providing enhanced strength and corrosion resistance. Kirksite, a zinc-aluminum alloy used primarily for diecasting, contains about 90% zinc and 10% aluminum with trace amounts of copper and magnesium, optimizing it for detailed casting with good dimensional stability. These chemical composition differences affect their mechanical properties, corrosion resistance, and suitability for specific manufacturing processes.

Mechanical Properties Comparison

Zamak alloys exhibit higher tensile strength and better corrosion resistance compared to Kirksite, making them suitable for applications requiring durability and wear resistance. Kirksite, an aluminum-zinc alloy, offers superior hardness and dimensional stability, ideal for precision tooling and die casting. The mechanical properties of Zamak include tensile strengths typically around 280 MPa, whereas Kirksite hardness measures 100-150 BHN, favoring hardness over ductility.

Applications of Zamak vs Kirksite

Zamak alloys are extensively used in die-casting for automotive parts, household appliances, and hardware due to their excellent strength, corrosion resistance, and dimensional stability. Kirksite, a zinc-aluminum alloy, is primarily applied in prototype and low-volume production tooling because of its superb machinability and fine detail replication capabilities. While Zamak suits mass production and structural components, Kirksite excels in precision molds and master patterns within injection molding and metal casting industries.

Manufacturing and Processing Techniques

Zamak alloys primarily involve die casting, utilizing high-pressure injection molding to achieve precise, complex shapes with excellent dimensional stability and surface finish. Kirksite, a zinc-aluminum alloy, is typically produced using gravity casting, which offers easier machinability but less accuracy and surface detail compared to Zamak die casting. The choice between Zamak and Kirksite depends on manufacturing requirements, with Zamak favored for high-volume, intricate parts and Kirksite suited for prototypes or components needing extensive machining.

Casting Performance and Mold Life

Zamak alloys exhibit superior casting performance with excellent fluidity and dimensional stability, enabling intricate and thin-walled components, while Kirksite, a zinc alloy primarily used for tooling dies, offers exceptional mold durability due to its high strength and wear resistance but lower fluidity limits intricate designs. Zamak's enhanced mold life is attributed to its reduced erosion and better thermal conductivity during casting cycles, whereas Kirksite molds require more maintenance despite longer lifespan in low-volume casting scenarios. The choice between Zamak and Kirksite depends on balancing the need for detail precision and mold longevity within production parameters.

Corrosion Resistance and Durability

Zamak alloys offer superior corrosion resistance compared to Kirksite due to their higher zinc purity and the addition of aluminum and magnesium, which form a stable oxide layer that protects the metal surface. Kirksite, primarily used for die casting molds, is softer and more prone to corrosion under harsh environmental conditions, making it less durable for long-term applications. Consequently, Zamak is preferred in manufacturing components requiring enhanced durability and resistance to oxidation.

Cost Analysis: Zamak vs Kirksite

Zamak alloys typically offer lower material costs due to widespread availability and efficient, large-scale production methods compared to Kirksite, which incurs higher expenses owing to its specialized zinc-aluminum-copper-magnesium composition and limited manufacturing processes. Kirksite's premium cost reflects superior mechanical properties and precision casting for complex molds in die casting, justifying its use in high-performance applications despite elevated prices. Cost analysis favors Zamak for mass production and economy but favors Kirksite for specialized tooling where durability and fine detail reduce long-term operational costs.

Environmental and Recycling Considerations

Zamak alloys are more environmentally favorable due to their higher recyclability and lower energy consumption during remelting compared to Kirksite, which contains higher lead content making it less eco-friendly. Zamak's composition allows for efficient recycling within the zinc industry, reducing waste and minimizing environmental impact. Conversely, Kirksite's lead complicates disposal and recycling processes, posing greater environmental hazards and regulatory challenges.

Choosing the Right Alloy for Your Project

Zamak alloys offer superior corrosion resistance and excellent dimensional stability, making them ideal for precision die casting in automotive and hardware applications. Kirksite, a zinc-aluminum alloy, excels in low-volume production and prototyping due to its ease of machining and shorter casting cycles. Selecting the right alloy depends on balancing production volume, mechanical strength, and finish quality required for your specific project needs.

Zamak vs Kirksite Infographic

materialdif.com

materialdif.com