Electroplated zinc coatings provide a smooth, aesthetically appealing finish ideal for small, precision-engineered pet components, offering moderate corrosion resistance primarily through sacrificial protection. Hot-dip galvanized zinc delivers a thicker, more durable layer with superior corrosion resistance, making it suitable for larger pet products exposed to harsh outdoor environments. Choosing between the two depends on the required durability, environmental exposure, and surface finish preferences in zinc-plated pet applications.

Table of Comparison

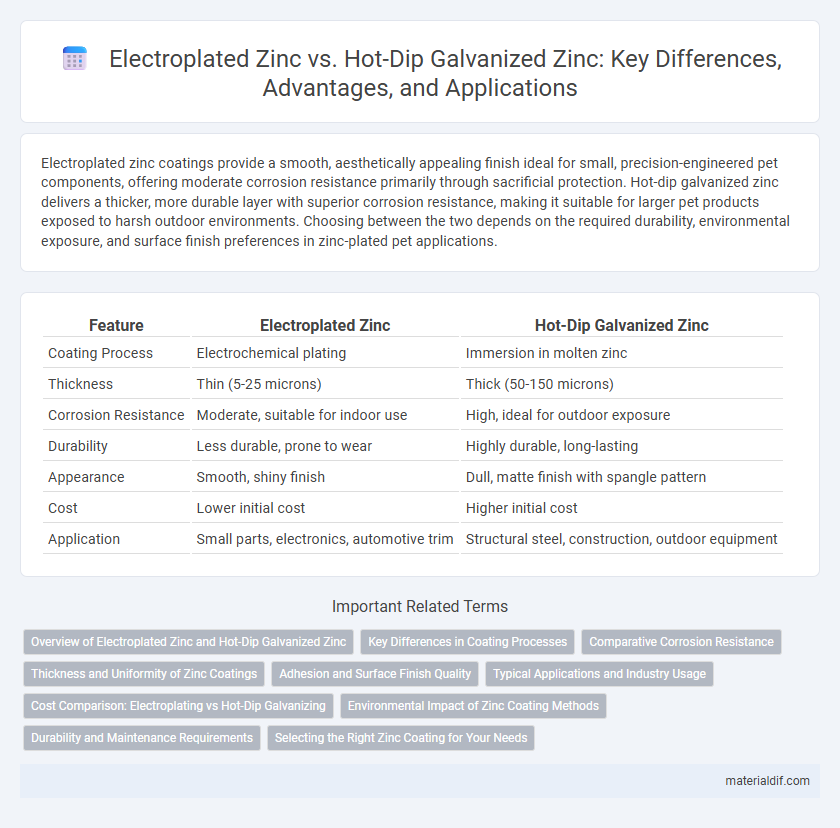

| Feature | Electroplated Zinc | Hot-Dip Galvanized Zinc |

|---|---|---|

| Coating Process | Electrochemical plating | Immersion in molten zinc |

| Thickness | Thin (5-25 microns) | Thick (50-150 microns) |

| Corrosion Resistance | Moderate, suitable for indoor use | High, ideal for outdoor exposure |

| Durability | Less durable, prone to wear | Highly durable, long-lasting |

| Appearance | Smooth, shiny finish | Dull, matte finish with spangle pattern |

| Cost | Lower initial cost | Higher initial cost |

| Application | Small parts, electronics, automotive trim | Structural steel, construction, outdoor equipment |

Overview of Electroplated Zinc and Hot-Dip Galvanized Zinc

Electroplated zinc involves applying a thin layer of zinc onto a metal surface using an electrical current, offering precise control over coating thickness and a smooth finish ideal for decorative and light-duty corrosion protection. Hot-dip galvanized zinc entails immersing steel or iron into molten zinc, creating a thicker, more robust coating that provides superior durability and corrosion resistance, especially in harsh outdoor environments. The choice between electroplated and hot-dip galvanized zinc depends on the specific application requirements such as coating thickness, environmental exposure, and aesthetic preferences.

Key Differences in Coating Processes

Electroplated zinc involves an electrical current to deposit a thin, uniform zinc layer onto a metal surface, offering precise control and a smooth finish ideal for small, intricate components. Hot-dip galvanized zinc, by contrast, submerges the metal in molten zinc, creating a thicker, more durable coating with superior corrosion resistance suited for structural steel exposed to harsh environments. The key differences lie in the coating thickness, adhesion strength, and durability, with hot-dip galvanizing providing a robust protective barrier compared to the more decorative and less wear-resistant electroplated zinc.

Comparative Corrosion Resistance

Electroplated zinc coatings provide a smooth, uniform finish with moderate corrosion resistance, typically protecting steel surfaces for months under normal atmospheric conditions. Hot-dip galvanized zinc offers superior corrosion resistance due to its thicker, metallurgically bonded layer, which endures harsh environments and aggressive weathering for several years without significant degradation. Studies indicate hot-dip galvanizing can extend the lifespan of steel structures by up to 20 times compared to electroplated zinc, making it the preferred choice for industrial and outdoor applications.

Thickness and Uniformity of Zinc Coatings

Electroplated zinc coatings typically range from 5 to 25 microns in thickness, providing a smooth and uniform layer ideal for decorative and light corrosion protection applications. Hot-dip galvanized zinc coatings are significantly thicker, often between 45 to 85 microns, forming a robust, multi-layered coating that ensures superior corrosion resistance and durability. The uniformity of electroplated zinc is controlled by precise electrical parameters, whereas hot-dip galvanizing results in a more variable but thicker and more protective zinc layer due to metallurgical bonding with the steel substrate.

Adhesion and Surface Finish Quality

Electroplated zinc coatings offer superior adhesion due to the precise control during the plating process, resulting in a smooth, uniform surface finish ideal for intricate components. Hot-dip galvanized zinc provides thicker, more durable protection with robust corrosion resistance, but typically features a rougher, uneven surface finish due to the molten zinc immersion. For applications where surface finish quality and adhesion are critical, electroplated zinc is preferred, whereas hot-dip galvanizing excels in heavy-duty environments requiring enhanced durability.

Typical Applications and Industry Usage

Electroplated zinc coatings are commonly used in automotive and electronics industries where precise, thin, and decorative finishes provide moderate corrosion protection and improved surface conductivity. Hot-dip galvanized zinc offers superior durability and corrosion resistance, making it ideal for heavy-duty applications such as construction, infrastructure, and outdoor steel structures exposed to harsh environmental conditions. Both processes serve critical roles, with electroplating favored for aesthetic and light-duty purposes, while hot-dip galvanizing is essential for long-term protection in industrial and structural applications.

Cost Comparison: Electroplating vs Hot-Dip Galvanizing

Electroplated zinc typically incurs higher costs due to its labor-intensive process and use of specialized chemicals, making it suitable for smaller, precision parts. Hot-dip galvanized zinc offers a more cost-effective solution for large-scale applications by providing thicker, more durable coatings through immersion in molten zinc. The choice between these methods largely depends on budget constraints and the specific performance requirements of the zinc coating.

Environmental Impact of Zinc Coating Methods

Electroplated zinc coatings typically involve the use of hazardous chemicals and generate toxic wastewater, posing greater environmental risks compared to hot-dip galvanizing. Hot-dip galvanized zinc provides durable corrosion resistance with fewer harmful emissions and higher recyclability, reducing its ecological footprint. Selecting hot-dip galvanizing supports sustainable practices by minimizing environmental contamination and resource consumption in zinc coating applications.

Durability and Maintenance Requirements

Electroplated zinc coatings provide a smooth, thin layer that offers moderate corrosion resistance but generally require more frequent maintenance due to their susceptibility to wear and environmental exposure. Hot-dip galvanized zinc involves immersing steel in molten zinc, creating a thicker, more durable coating with superior corrosion protection and reduced maintenance needs over time. The enhanced longevity of hot-dip galvanizing is attributed to its robust metallurgical bonding and zinc-iron alloy layers, making it ideal for harsh or outdoor environments.

Selecting the Right Zinc Coating for Your Needs

Electroplated zinc coatings provide a thin, uniform layer ideal for decorative and light corrosion protection on small components, while hot-dip galvanized zinc coatings offer a thicker, more durable barrier suited for heavy-duty outdoor applications and structural steel. Selecting the right zinc coating depends on factors such as exposure to environmental elements, desired longevity, and mechanical wear resistance requirements. For marine or industrial environments, hot-dip galvanizing ensures superior corrosion resistance, whereas electroplating is preferable for precision parts needing a fine finish.

Electroplated Zinc vs Hot-Dip Galvanized Zinc Infographic

materialdif.com

materialdif.com