ZAM coating offers excellent corrosion resistance with a smooth, bright finish, making it ideal for lightweight automotive and appliance applications. Zinc-nickel coating provides superior protection against harsh environments, especially in aerospace and marine industries, due to its enhanced durability and resistance to white rust. Both coatings serve distinct purposes based on environmental exposure and performance requirements, with zinc-nickel favored for long-term corrosion prevention and ZAM valued for cost-effective efficiency.

Table of Comparison

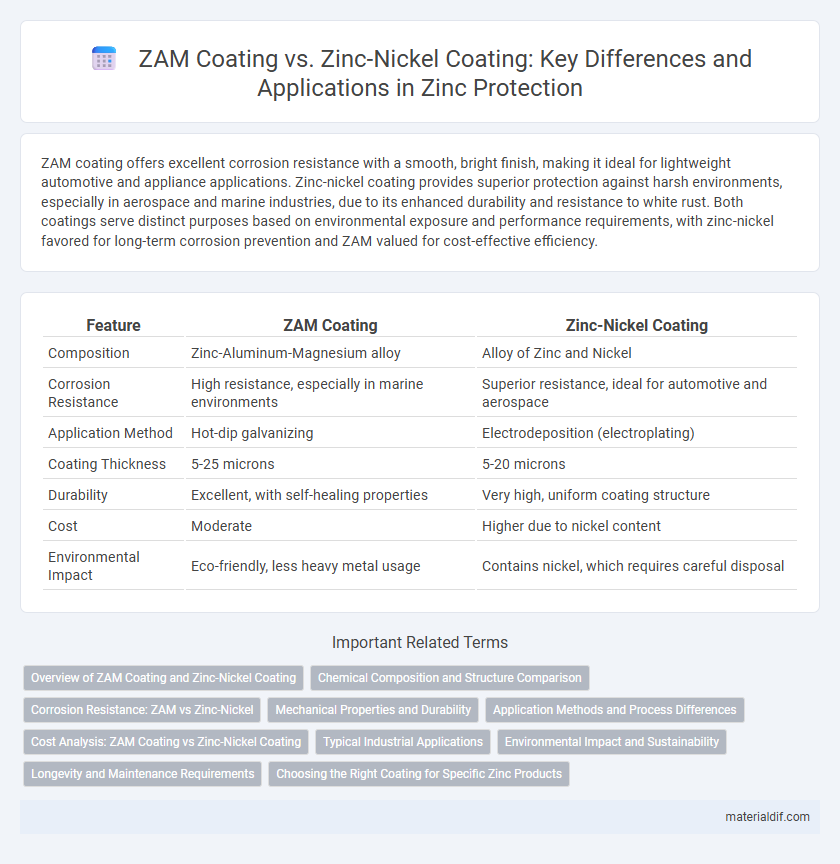

| Feature | ZAM Coating | Zinc-Nickel Coating |

|---|---|---|

| Composition | Zinc-Aluminum-Magnesium alloy | Alloy of Zinc and Nickel |

| Corrosion Resistance | High resistance, especially in marine environments | Superior resistance, ideal for automotive and aerospace |

| Application Method | Hot-dip galvanizing | Electrodeposition (electroplating) |

| Coating Thickness | 5-25 microns | 5-20 microns |

| Durability | Excellent, with self-healing properties | Very high, uniform coating structure |

| Cost | Moderate | Higher due to nickel content |

| Environmental Impact | Eco-friendly, less heavy metal usage | Contains nickel, which requires careful disposal |

Overview of ZAM Coating and Zinc-Nickel Coating

ZAM coating is an alloy-based protective layer composed primarily of zinc, aluminum, and magnesium, offering excellent corrosion resistance and enhanced durability compared to pure zinc coatings. Zinc-nickel coating consists of a zinc and nickel alloy deposited through electroplating, providing superior corrosion protection, especially in high-temperature and aggressive environments, with enhanced wear resistance. Both coatings improve substrate longevity but differ in chemical composition, application processes, and performance characteristics tailored to specific industrial requirements.

Chemical Composition and Structure Comparison

ZAM coating consists mainly of zinc, aluminum (around 3%), and magnesium (about 3%), forming a metallurgical layer that delivers excellent corrosion resistance through sacrificial protection. Zinc-nickel coating typically contains 85-90% zinc and 10-15% nickel, creating a dense, uniform alloy layer that offers superior corrosion resistance compared to pure zinc coatings due to the nickel's barrier effect. Structurally, ZAM forms intermetallic layers of Zn, Al, and Mg, enhancing self-healing properties, while zinc-nickel coatings form a compact alloy layer with higher hardness and improved wear resistance.

Corrosion Resistance: ZAM vs Zinc-Nickel

ZAM coating, an alloy primarily composed of zinc, aluminum, and magnesium, offers excellent corrosion resistance by forming a protective barrier that slows down rust formation on steel surfaces. Zinc-nickel coating provides superior corrosion protection in harsh environments due to its higher nickel content, which enhances passivation and reduces oxidation rates significantly. Comparative studies indicate zinc-nickel coatings outperform ZAM in salt spray tests, extending the lifespan of coated components in marine and industrial applications.

Mechanical Properties and Durability

ZAM coating, a zinc-aluminum-magnesium alloy, offers excellent corrosion resistance and superior mechanical properties such as enhanced hardness and ductility compared to traditional zinc coatings. Zinc-nickel coatings provide outstanding durability with exceptional wear resistance and higher corrosion protection, especially in harsh environments like marine or automotive applications. While ZAM coatings excel in flexibility and impact resistance, zinc-nickel coatings are preferred for superior longevity and performance under extreme conditions.

Application Methods and Process Differences

ZAM coating, primarily composed of zinc, aluminum, and magnesium, is applied through hot-dip galvanizing, which involves immersing steel components into molten metal for corrosion resistance. Zinc-nickel coating utilizes electroplating, where an electrical current deposits a zinc-nickel alloy onto the substrate, offering enhanced durability and heat resistance. The key process difference lies in ZAM's metallurgical bonding from hot-dipping versus zinc-nickel's controlled alloy thickness and composition from electrochemical deposition.

Cost Analysis: ZAM Coating vs Zinc-Nickel Coating

ZAM coating, primarily composed of zinc, aluminum, and magnesium, generally offers a lower cost solution compared to zinc-nickel coating due to its simpler alloy composition and less expensive raw materials. Zinc-nickel coating, while more costly, provides superior corrosion resistance and durability in harsh environments, justifying the higher investment for critical applications. Cost analysis reveals ZAM coating is optimal for budget-sensitive projects requiring moderate protection, whereas zinc-nickel coating suits high-performance needs despite its premium price.

Typical Industrial Applications

ZAM coating, composed primarily of zinc, aluminum, and magnesium, offers excellent corrosion resistance ideal for automotive parts, agricultural machinery, and fasteners exposed to harsh environments. Zinc-nickel coating provides superior corrosion protection with enhanced wear resistance, commonly used in aerospace components, automotive fuel systems, and electronic connectors where durability and long-term performance are critical. Both coatings serve industrial sectors requiring reliable protection against rust, but zinc-nickel coatings excel in high-stress, high-temperature applications.

Environmental Impact and Sustainability

ZAM coating, an alloy of zinc, aluminum, and magnesium, offers superior corrosion resistance with less environmental toxicity compared to traditional zinc-nickel coatings, which contain higher levels of heavy metals like nickel that pose ecological risks. The reduced use of hazardous substances in ZAM coatings aligns with sustainable manufacturing goals by minimizing waste treatment challenges and lowering the environmental footprint. Sustainable zinc-based coatings like ZAM contribute to longer-lasting protective layers, decreasing the frequency of reapplications and conserving raw material resources over time.

Longevity and Maintenance Requirements

ZAM coating offers excellent corrosion resistance with a longer lifespan than traditional zinc coatings, reducing the frequency of maintenance. Zinc-nickel coatings provide superior durability and enhanced protection in harsh environments, extending service life beyond that of ZAM coatings. Maintenance requirements for zinc-nickel coatings are lower due to their higher resistance to wear, corrosion, and oxidation.

Choosing the Right Coating for Specific Zinc Products

ZAM coating, an alloy of zinc, aluminum, and magnesium, offers superior corrosion resistance ideal for automotive and construction applications requiring extended durability. Zinc-nickel coating provides enhanced wear resistance and high corrosion protection, making it suitable for aerospace and high-stress mechanical parts. Selecting between ZAM and zinc-nickel coatings depends on environmental exposure, mechanical requirements, and expected service life of specific zinc products.

ZAM Coating vs Zinc-Nickel Coating Infographic

materialdif.com

materialdif.com