Organic coated zinc offers enhanced bioavailability and reduced environmental impact compared to inorganic coated zinc, making it a superior choice for pet nutrition. The organic coating improves zinc absorption in pets, supporting immune function and skin health more effectively than inorganic forms. Inorganic coated zinc, while often more affordable, tends to have lower absorption rates and may contribute to environmental contamination due to higher leaching potential.

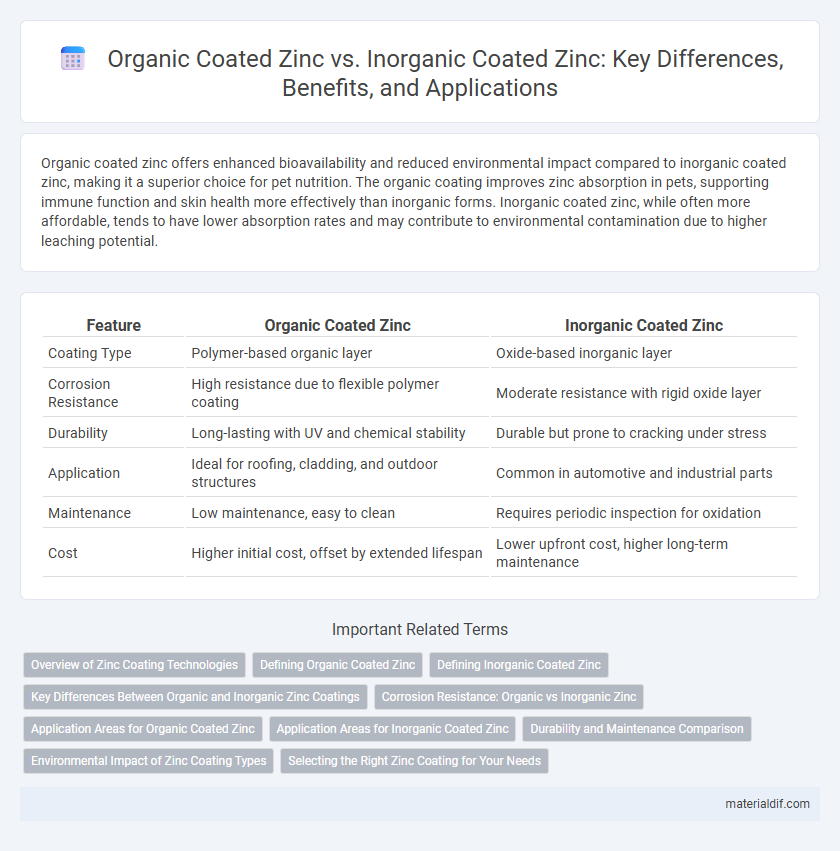

Table of Comparison

| Feature | Organic Coated Zinc | Inorganic Coated Zinc |

|---|---|---|

| Coating Type | Polymer-based organic layer | Oxide-based inorganic layer |

| Corrosion Resistance | High resistance due to flexible polymer coating | Moderate resistance with rigid oxide layer |

| Durability | Long-lasting with UV and chemical stability | Durable but prone to cracking under stress |

| Application | Ideal for roofing, cladding, and outdoor structures | Common in automotive and industrial parts |

| Maintenance | Low maintenance, easy to clean | Requires periodic inspection for oxidation |

| Cost | Higher initial cost, offset by extended lifespan | Lower upfront cost, higher long-term maintenance |

Overview of Zinc Coating Technologies

Organic coated zinc offers enhanced corrosion resistance and aesthetic appeal by applying polymer-based films that act as protective barriers, while inorganic coated zinc typically involves conversion coatings such as chromates or phosphates that improve adhesion and provide basic corrosion protection. Both technologies extend the lifespan of steel substrates, but organic coatings allow for greater customization with colors and textures, making them suitable for architectural applications. Inorganic coatings remain cost-effective and are widely used in industrial environments due to their simplicity and durability.

Defining Organic Coated Zinc

Organic coated zinc refers to zinc metal surfaces treated with polymer-based layers that provide enhanced corrosion resistance and aesthetic appeal. These coatings typically include polymers such as epoxy, polyurethane, or polyester, forming a protective barrier against environmental factors like moisture and pollutants. Compared to inorganic coatings, organic coatings offer improved flexibility, adhesion, and durability in various industrial applications.

Defining Inorganic Coated Zinc

Inorganic coated zinc refers to zinc metal layers protected by inorganic compounds such as zinc oxide or zinc chromate, which provide corrosion resistance through a chemically stable barrier. These coatings typically exhibit excellent durability in harsh environments and maintain their protective properties without organic material degradation. Inorganic coatings are favored for applications requiring high thermal stability and resistance to ultraviolet light compared to organic coated zinc.

Key Differences Between Organic and Inorganic Zinc Coatings

Organic coated zinc offers superior corrosion resistance due to its polymer-based layer, which acts as a barrier against moisture and contaminants. Inorganic coated zinc relies on metallic or ceramic compounds, providing excellent adhesion and durability but may be more susceptible to cracking under stress. The choice between organic and inorganic zinc coatings depends on environmental exposure and required lifespan, with organic coatings favored for flexibility and inorganic for high-temperature stability.

Corrosion Resistance: Organic vs Inorganic Zinc

Organic coated zinc offers superior corrosion resistance by forming a flexible, adherent barrier that prevents moisture and oxygen penetration, significantly extending the lifespan of metal surfaces. In contrast, inorganic coated zinc, typically based on zinc oxide or chromate layers, provides a more rigid protective film with excellent initial corrosion resistance but may crack under mechanical stress, reducing its long-term effectiveness. Studies show organic coatings excel in resisting environmental factors such as salt spray and humidity, making them preferable for harsh and marine environments.

Application Areas for Organic Coated Zinc

Organic coated zinc is widely used in architectural cladding, roofing systems, and automotive components due to its superior corrosion resistance and aesthetic versatility. Its polymer-based coatings provide enhanced protection against environmental factors, making it ideal for outdoor applications in both industrial and residential buildings. The organic layers also allow for customizable colors and finishes, expanding design possibilities in construction and decorative metalwork.

Application Areas for Inorganic Coated Zinc

Inorganic coated zinc is widely utilized in construction and automotive industries due to its superior corrosion resistance and durability in harsh environments. It serves as a protective layer for steel structures, roofing panels, and automotive body parts, enhancing longevity and reducing maintenance costs. Applications also extend to electrical and industrial equipment where consistent performance under extreme conditions is critical.

Durability and Maintenance Comparison

Organic coated zinc offers superior durability compared to inorganic coated zinc due to its enhanced resistance to corrosion and UV degradation, resulting in longer service life. Maintenance requirements for organic coatings are typically lower, as their flexible polymer layers prevent cracking and reduce the need for frequent touch-ups. In contrast, inorganic coatings, while cost-effective initially, often require more regular inspections and reapplications to maintain protective properties against environmental factors.

Environmental Impact of Zinc Coating Types

Organic coated zinc uses polymer-based layers that enhance corrosion resistance while reducing environmental pollution compared to traditional inorganic coatings, which often contain heavy metals like chromates harmful to ecosystems. The production and disposal of organic coatings result in fewer toxic byproducts and lower emissions, supporting sustainable manufacturing practices. Inorganic coated zinc, although effective in protection, tends to contribute more to soil and water contamination due to the leaching of hazardous substances over time.

Selecting the Right Zinc Coating for Your Needs

Organic coated zinc offers superior corrosion resistance and aesthetic flexibility, making it ideal for architectural applications requiring long-term durability and custom finishes. In contrast, inorganic coated zinc typically provides a thinner, more economical protective layer suitable for industrial structures where cost efficiency and basic protection are priorities. Choosing the right zinc coating depends on factors such as environmental exposure, maintenance requirements, and project budget to ensure optimal performance and longevity.

Organic Coated Zinc vs Inorganic Coated Zinc Infographic

materialdif.com

materialdif.com