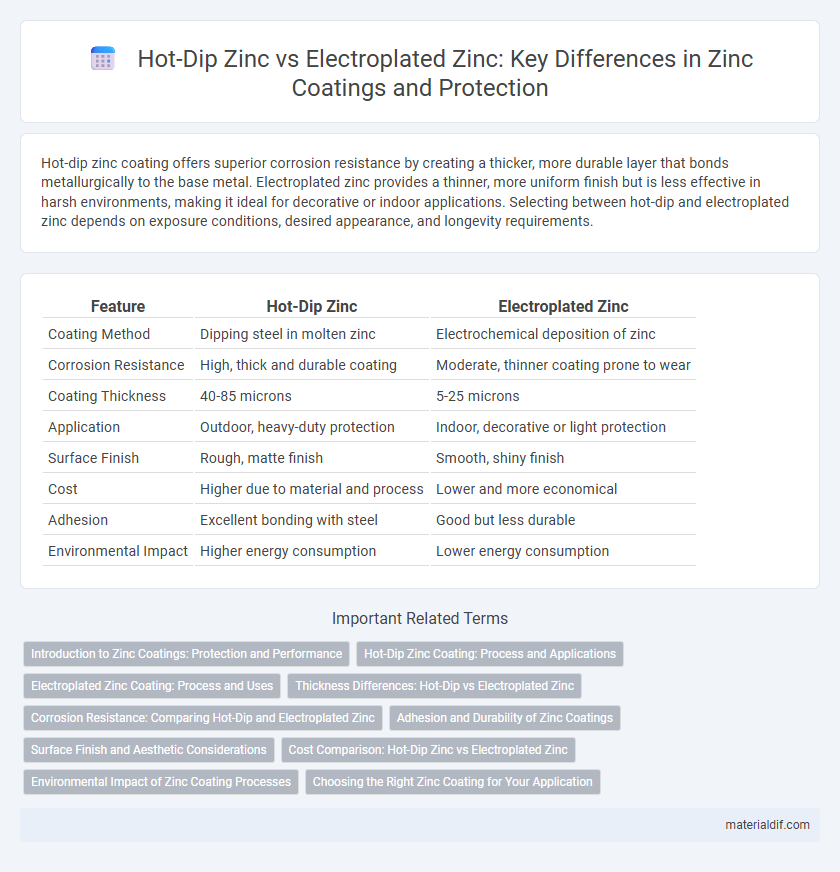

Hot-dip zinc coating offers superior corrosion resistance by creating a thicker, more durable layer that bonds metallurgically to the base metal. Electroplated zinc provides a thinner, more uniform finish but is less effective in harsh environments, making it ideal for decorative or indoor applications. Selecting between hot-dip and electroplated zinc depends on exposure conditions, desired appearance, and longevity requirements.

Table of Comparison

| Feature | Hot-Dip Zinc | Electroplated Zinc |

|---|---|---|

| Coating Method | Dipping steel in molten zinc | Electrochemical deposition of zinc |

| Corrosion Resistance | High, thick and durable coating | Moderate, thinner coating prone to wear |

| Coating Thickness | 40-85 microns | 5-25 microns |

| Application | Outdoor, heavy-duty protection | Indoor, decorative or light protection |

| Surface Finish | Rough, matte finish | Smooth, shiny finish |

| Cost | Higher due to material and process | Lower and more economical |

| Adhesion | Excellent bonding with steel | Good but less durable |

| Environmental Impact | Higher energy consumption | Lower energy consumption |

Introduction to Zinc Coatings: Protection and Performance

Hot-dip zinc coatings offer superior corrosion resistance by forming a thick, metallurgically bonded layer through immersion in molten zinc, making them ideal for harsh environments. Electroplated zinc coatings provide a thinner, more uniform zinc layer that enhances appearance and is suitable for indoor or less aggressive conditions. Both methods protect steel substrates by sacrificially corroding zinc, preventing rust and extending the lifespan of metal components.

Hot-Dip Zinc Coating: Process and Applications

Hot-dip zinc coating involves immersing steel components in molten zinc at approximately 450degC, creating a robust metallurgical bond that ensures superior corrosion resistance compared to electroplated zinc. This process produces thick, durable layers that protect steel in harsh environments, making it ideal for automotive parts, construction materials, and infrastructure components exposed to outdoor conditions. Hot-dip galvanizing offers long-lasting protection by forming zinc-iron alloy layers and a pure zinc outer layer, significantly extending the lifespan of steel products.

Electroplated Zinc Coating: Process and Uses

Electroplated zinc coating involves depositing a thin layer of zinc onto a metal surface through an electrochemical process, enhancing corrosion resistance and surface finish. This method is widely used in automotive parts, electrical components, and hardware, offering precise control over coating thickness and uniformity. Electroplated zinc provides excellent adhesion and a smooth, decorative appearance, making it ideal for applications requiring both protection and aesthetics.

Thickness Differences: Hot-Dip vs Electroplated Zinc

Hot-dip zinc coatings typically range from 45 to 100 microns in thickness, providing robust corrosion resistance suitable for industrial applications. Electroplated zinc coatings are much thinner, usually between 5 to 25 microns, ideal for decorative purposes and light-duty protection. The substantial thickness difference allows hot-dip zinc to offer prolonged durability in harsh environments compared to the more delicate electroplated zinc layer.

Corrosion Resistance: Comparing Hot-Dip and Electroplated Zinc

Hot-dip zinc coatings offer superior corrosion resistance compared to electroplated zinc due to their thicker, metallurgically bonded layers that provide long-lasting protection against rust and environmental exposure. Electroplated zinc, while providing a smoother finish and better aesthetic appearance, typically has thinner layers that wear away quicker, reducing its durability in harsh conditions. For industrial applications requiring enhanced longevity and resistance to corrosion, hot-dip galvanizing remains the preferred choice.

Adhesion and Durability of Zinc Coatings

Hot-dip zinc coatings exhibit superior adhesion and durability compared to electroplated zinc due to the metallurgical bonding formed during the immersion process, creating a thicker, more robust zinc-iron alloy layer. This results in enhanced corrosion resistance and longer service life, especially in harsh environments. Electroplated zinc, while providing a smoother finish, generally offers thinner coatings with weaker adhesion, making it less durable under mechanical stress or prolonged exposure to corrosive elements.

Surface Finish and Aesthetic Considerations

Hot-dip zinc coating provides a thicker, more durable surface finish with a characteristic spangled texture that enhances corrosion resistance for outdoor applications. Electroplated zinc offers a smoother, more uniform finish, preferred for indoor use where aesthetic appeal and precise detailing are critical. The choice between hot-dip and electroplated zinc depends on balancing surface durability with desired aesthetic quality in specific environmental conditions.

Cost Comparison: Hot-Dip Zinc vs Electroplated Zinc

Hot-dip zinc coating typically incurs higher initial costs compared to electroplated zinc due to more complex equipment and prolonged processing times. However, hot-dip zinc offers superior corrosion resistance and durability, reducing long-term maintenance expenses and replacement frequency, which can lower overall lifecycle costs. Electroplated zinc is more cost-effective for thin, decorative coatings but may lead to higher long-term costs in harsh environments due to less robust protection.

Environmental Impact of Zinc Coating Processes

Hot-dip zinc coating involves immersing steel in molten zinc, creating a thicker and more durable layer that offers superior corrosion resistance, reducing the need for frequent replacements and minimizing waste. Electroplated zinc uses an electric current to deposit a thinner zinc layer, consuming less zinc material but often requiring hazardous chemicals and generating more toxic wastewater. Hot-dip galvanizing has a higher initial energy footprint but leads to a longer service life and lower environmental impact over time, while electroplating demands stricter waste management to mitigate environmental contamination.

Choosing the Right Zinc Coating for Your Application

Hot-dip zinc coatings offer superior corrosion resistance and durability, making them ideal for outdoor and industrial applications exposed to harsh environments. Electroplated zinc provides a thinner, more uniform finish suited for decorative purposes and indoor use where aesthetics and precise dimensions are critical. Selecting the right zinc coating depends on environmental exposure, desired lifespan, and specific functional requirements of the application.

Hot-Dip Zinc vs Electroplated Zinc Infographic

materialdif.com

materialdif.com