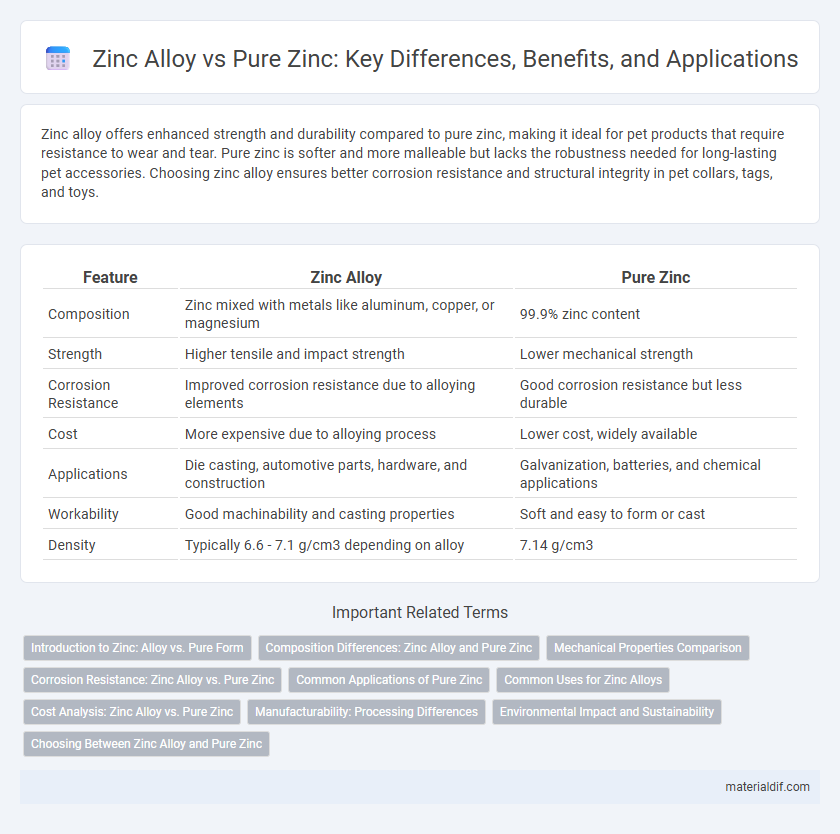

Zinc alloy offers enhanced strength and durability compared to pure zinc, making it ideal for pet products that require resistance to wear and tear. Pure zinc is softer and more malleable but lacks the robustness needed for long-lasting pet accessories. Choosing zinc alloy ensures better corrosion resistance and structural integrity in pet collars, tags, and toys.

Table of Comparison

| Feature | Zinc Alloy | Pure Zinc |

|---|---|---|

| Composition | Zinc mixed with metals like aluminum, copper, or magnesium | 99.9% zinc content |

| Strength | Higher tensile and impact strength | Lower mechanical strength |

| Corrosion Resistance | Improved corrosion resistance due to alloying elements | Good corrosion resistance but less durable |

| Cost | More expensive due to alloying process | Lower cost, widely available |

| Applications | Die casting, automotive parts, hardware, and construction | Galvanization, batteries, and chemical applications |

| Workability | Good machinability and casting properties | Soft and easy to form or cast |

| Density | Typically 6.6 - 7.1 g/cm3 depending on alloy | 7.14 g/cm3 |

Introduction to Zinc: Alloy vs. Pure Form

Zinc alloy combines zinc with other metals such as aluminum, copper, or magnesium, enhancing strength, corrosion resistance, and durability compared to pure zinc. Pure zinc exhibits excellent corrosion resistance and is highly malleable, making it ideal for applications like galvanization and die-casting where flexibility and protective properties are essential. Selecting between zinc alloy and pure zinc depends on specific requirements, balancing enhanced mechanical properties of alloys against the natural purity and workability of elemental zinc.

Composition Differences: Zinc Alloy and Pure Zinc

Zinc alloy consists of zinc combined with other metals such as copper, aluminum, or magnesium, enhancing mechanical strength and corrosion resistance compared to pure zinc. Pure zinc is nearly 99.9% zinc, offering excellent corrosion resistance but limited structural integrity and hardness. The varied composition in zinc alloys tailors properties for specific applications, while pure zinc remains favored for coatings and sacrificial anodes.

Mechanical Properties Comparison

Zinc alloys exhibit superior mechanical properties compared to pure zinc, including higher tensile strength and improved hardness, which enhance durability in industrial applications. Pure zinc typically has lower ductility and strength, limiting its use in structural components where load-bearing capacity is critical. The addition of elements such as aluminum, copper, and magnesium in zinc alloys significantly improves corrosion resistance and impact toughness, making them more suitable for manufacturing hardware and automotive parts.

Corrosion Resistance: Zinc Alloy vs. Pure Zinc

Zinc alloys exhibit enhanced corrosion resistance compared to pure zinc due to the presence of other metals such as copper, aluminum, and magnesium, which improve the protective oxide layer's durability. Pure zinc forms a relatively soft, less stable oxide coating that can degrade faster in aggressive environments, leading to quicker corrosion. The alloyed zinc's microstructure optimizes resistance to galvanic corrosion, making it suitable for industrial applications requiring long-term durability.

Common Applications of Pure Zinc

Pure zinc is widely used in galvanization to protect steel and iron from rusting, enhancing durability in construction and automotive industries. It serves as a key component in batteries, such as alkaline and zinc-carbon cells, due to its excellent electrochemical properties. Additionally, pure zinc is utilized in die casting for electrical components and corrosion-resistant coatings.

Common Uses for Zinc Alloys

Zinc alloys are commonly used in die-casting for automotive parts, electrical components, and hardware due to their enhanced strength and corrosion resistance compared to pure zinc. These alloys offer improved machinability and durability, making them ideal for precision components in consumer electronics and construction materials. Pure zinc, while primarily used for galvanizing steel and producing zinc oxide, lacks the mechanical properties required for structural applications where zinc alloys excel.

Cost Analysis: Zinc Alloy vs. Pure Zinc

Zinc alloys generally offer a more cost-effective solution compared to pure zinc due to their enhanced mechanical properties that reduce material usage and improve manufacturing efficiency. The addition of elements like aluminum, copper, and magnesium in zinc alloys lowers production costs by increasing durability and minimizing waste during casting processes. Pure zinc, while cheaper per unit weight, often results in higher overall expenses due to increased brittleness and longer processing times.

Manufacturability: Processing Differences

Zinc alloys exhibit superior machinability and casting properties compared to pure zinc, resulting in enhanced manufacturability for intricate components. Pure zinc tends to have lower melting points and higher brittleness, complicating processing and limiting its application in precision manufacturing. The addition of alloying elements like aluminum, copper, and magnesium in zinc alloys improves strength and reduces shrinkage, enabling more efficient production and higher-quality finished products.

Environmental Impact and Sustainability

Zinc alloy offers enhanced durability and corrosion resistance compared to pure zinc, reducing the frequency of replacements and waste generation in industrial applications. Pure zinc, while more environmentally benign during recycling due to its simpler composition, often requires higher energy inputs for frequent production cycles caused by its lower mechanical strength. Selecting zinc alloy can contribute to sustainability by extending product life and minimizing resource consumption despite a more complex recycling process.

Choosing Between Zinc Alloy and Pure Zinc

Choosing between zinc alloy and pure zinc depends on the desired balance of strength, corrosion resistance, and cost. Zinc alloys, often combined with elements like aluminum, copper, or magnesium, offer enhanced mechanical properties and durability compared to pure zinc, making them ideal for structural applications. Pure zinc provides superior corrosion resistance and is typically used in galvanizing and protective coatings where environmental exposure is a primary concern.

Zinc Alloy vs Pure Zinc Infographic

materialdif.com

materialdif.com