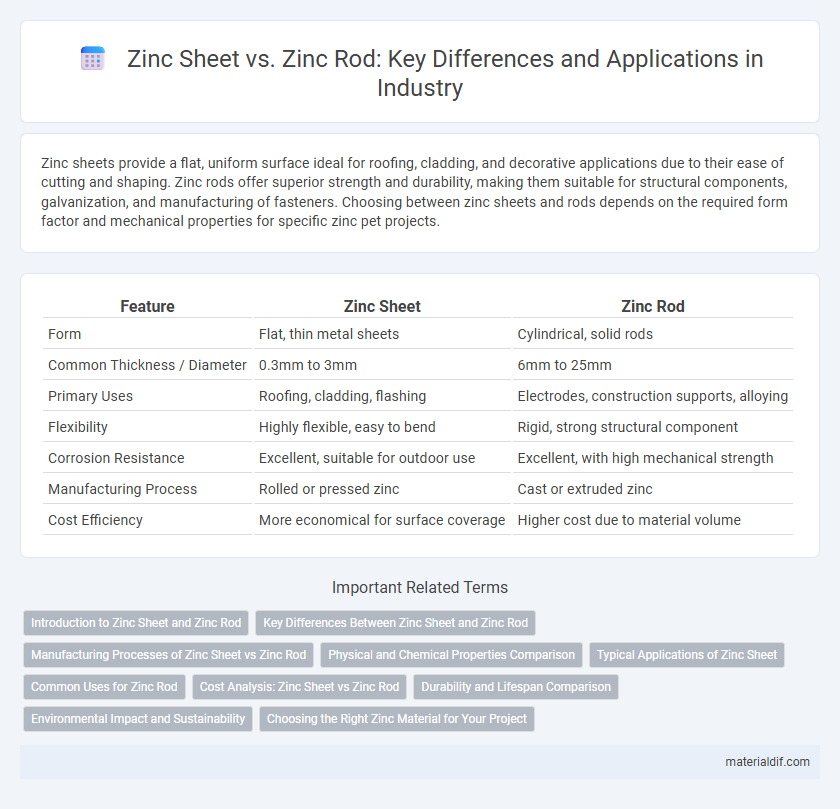

Zinc sheets provide a flat, uniform surface ideal for roofing, cladding, and decorative applications due to their ease of cutting and shaping. Zinc rods offer superior strength and durability, making them suitable for structural components, galvanization, and manufacturing of fasteners. Choosing between zinc sheets and rods depends on the required form factor and mechanical properties for specific zinc pet projects.

Table of Comparison

| Feature | Zinc Sheet | Zinc Rod |

|---|---|---|

| Form | Flat, thin metal sheets | Cylindrical, solid rods |

| Common Thickness / Diameter | 0.3mm to 3mm | 6mm to 25mm |

| Primary Uses | Roofing, cladding, flashing | Electrodes, construction supports, alloying |

| Flexibility | Highly flexible, easy to bend | Rigid, strong structural component |

| Corrosion Resistance | Excellent, suitable for outdoor use | Excellent, with high mechanical strength |

| Manufacturing Process | Rolled or pressed zinc | Cast or extruded zinc |

| Cost Efficiency | More economical for surface coverage | Higher cost due to material volume |

Introduction to Zinc Sheet and Zinc Rod

Zinc sheets are thin, flat pieces of zinc commonly used in roofing, cladding, and waterproofing due to their malleability and corrosion resistance. Zinc rods are cylindrical zinc products primarily employed in galvanization, alloy production, and electroplating processes for durability and protection against rust. Selecting between zinc sheet and zinc rod depends on application requirements such as shape, thickness, and mechanical properties.

Key Differences Between Zinc Sheet and Zinc Rod

Zinc sheets are flat, thin, and typically used in roofing, cladding, and various architectural applications due to their ease of shaping and large surface coverage. Zinc rods, in contrast, have a cylindrical shape and are primarily employed in manufacturing, electrical grounding, and as raw material for producing alloys. The key differences lie in their form factor, application scope, and fabrication methods, with sheets offering versatility in surface-based projects and rods serving structural and industrial purposes.

Manufacturing Processes of Zinc Sheet vs Zinc Rod

Zinc sheets are typically produced through hot rolling or cold rolling processes, where molten zinc is cast into slabs and then rolled into thin, flat sheets with uniform thickness. Zinc rods are manufactured by continuous casting or extrusion, shaping molten zinc into cylindrical forms that solidify into rods with consistent diameter and surface finish. The rolling process for sheets enhances surface smoothness and dimensional accuracy, while extrusion or continuous casting for rods allows precise control over cross-sectional shape and mechanical properties.

Physical and Chemical Properties Comparison

Zinc sheets exhibit high malleability and a smooth surface ideal for corrosion-resistant applications, while zinc rods possess greater tensile strength and rigidity suited for structural uses. Chemically, both forms have a similar purity level with a typical composition of over 99% zinc, offering excellent resistance to oxidation and chemical corrosion in various environments. The difference in physical form affects thermal conductivity, with sheets providing more surface area for heat dissipation compared to the compact shape of rods.

Typical Applications of Zinc Sheet

Zinc sheets are commonly used in roofing, cladding, and gutters due to their flexibility, corrosion resistance, and ease of fabrication, making them ideal for architectural and construction projects. They are also favored in flashing and decorative elements where thin, malleable metal is required. Zinc rods, in contrast, are typically utilized in galvanizing and alloy production rather than surface applications.

Common Uses for Zinc Rod

Zinc rods are commonly used in galvanic protection systems, electrical applications, and manufacturing of zinc-based alloys due to their excellent conductivity and corrosion resistance. Unlike zinc sheets that are favored for cladding and roofing, zinc rods are essential in producing cathodic protection anodes and custom metal components. Their structural integrity and ease of machining make zinc rods ideal for industrial and architectural uses requiring precision and durability.

Cost Analysis: Zinc Sheet vs Zinc Rod

Zinc sheet typically offers a lower cost per square meter compared to zinc rod due to its flat form and ease of manufacturing, making it more economical for large surface applications. Zinc rods incur higher costs as they require more energy-intensive extrusion or drawing processes, and their use is generally limited to specialized applications like galvanizing or metal joining. Evaluating project requirements against material prices reveals zinc sheets provide better value for roofing and cladding, while zinc rods justify their expense in structural reinforcement or alloy production.

Durability and Lifespan Comparison

Zinc sheets offer greater durability and resistance to environmental wear due to their uniform thickness and surface finish, making them ideal for roofing and cladding applications where long-term performance is critical. Zinc rods, while sturdy, are more susceptible to surface corrosion over time without protective coatings, limiting their lifespan in outdoor or high-moisture environments. The lifespan of zinc sheets can exceed 80 years under optimal conditions, whereas zinc rods typically last around 40 to 50 years depending on exposure and treatment.

Environmental Impact and Sustainability

Zinc sheets typically have a lower environmental impact compared to zinc rods due to their manufacturing process, which often involves less energy consumption and material waste. Zinc sheets are highly recyclable and contribute to sustainability by enabling efficient reuse in construction and industrial applications. In contrast, zinc rods, while durable, require more intensive resource extraction and processing, leading to a higher carbon footprint and less overall sustainability.

Choosing the Right Zinc Material for Your Project

Selecting the appropriate zinc material depends on the specific application requirements; zinc sheets offer excellent corrosion resistance and easy fabrication for roofing, cladding, and decorative purposes. Zinc rods provide superior strength and are ideal for structural components, galvanizing, and manufacturing fasteners or electrical contacts. Evaluate project demands such as formability, strength, and surface finish to ensure optimal performance and durability.

Zinc sheet vs Zinc rod Infographic

materialdif.com

materialdif.com