Zinc oxide offers superior UV protection and antimicrobial properties, making it ideal for pet care products such as sunscreens and wound treatments. In contrast, zinc sulfide is primarily used in pigments and luminescent materials but lacks the biocompatibility required for safe topical pet applications. Choosing zinc oxide ensures effective skin protection and safety for pets.

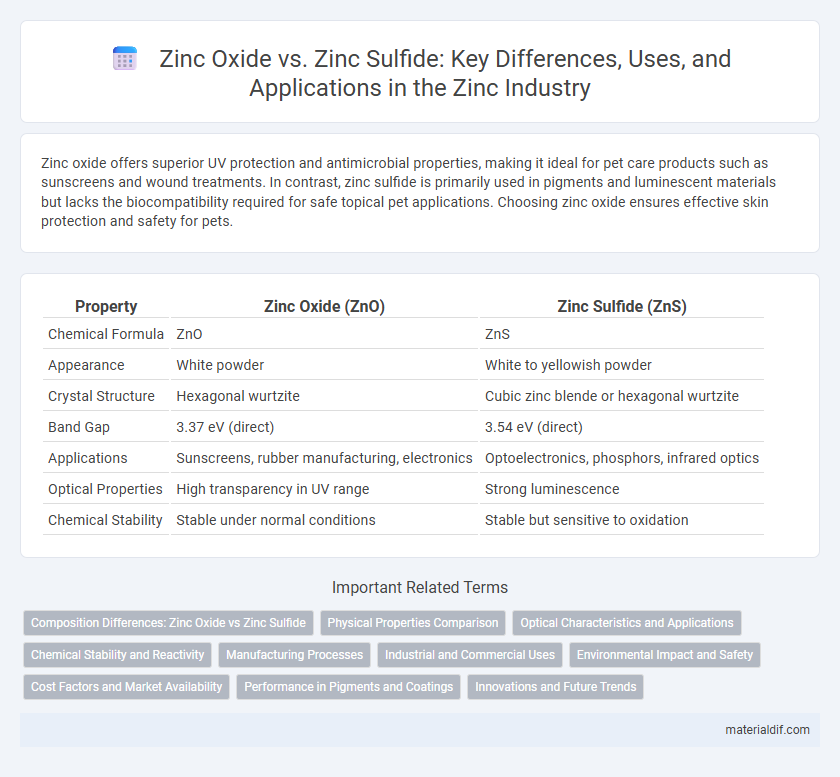

Table of Comparison

| Property | Zinc Oxide (ZnO) | Zinc Sulfide (ZnS) |

|---|---|---|

| Chemical Formula | ZnO | ZnS |

| Appearance | White powder | White to yellowish powder |

| Crystal Structure | Hexagonal wurtzite | Cubic zinc blende or hexagonal wurtzite |

| Band Gap | 3.37 eV (direct) | 3.54 eV (direct) |

| Applications | Sunscreens, rubber manufacturing, electronics | Optoelectronics, phosphors, infrared optics |

| Optical Properties | High transparency in UV range | Strong luminescence |

| Chemical Stability | Stable under normal conditions | Stable but sensitive to oxidation |

Composition Differences: Zinc Oxide vs Zinc Sulfide

Zinc oxide (ZnO) consists of zinc ions bonded to oxygen ions, forming a stable metal oxide with a wide bandgap of 3.37 eV, making it effective for UV protection and semiconductor applications. In contrast, zinc sulfide (ZnS) features zinc ions combined with sulfur ions, possessing a slightly smaller bandgap around 3.54 eV (in its cubic form), which imparts distinct optical properties suitable for phosphors and photodetectors. The fundamental compositional difference between the oxide and sulfide manifests in their electronic structures, crystal lattices, and resulting physical and chemical behaviors.

Physical Properties Comparison

Zinc oxide exhibits a white, powdery appearance with a melting point of 1975degC and a hexagonal crystal structure, making it highly stable and widely used in sunscreens and rubber production. Zinc sulfide, characterized by its pale yellow to white color, has a lower melting point of 1650degC and typically forms a cubic crystal lattice, which provides distinct optical properties utilized in phosphorescent and luminescent applications. Both compounds demonstrate high refractive indices, but zinc sulfide's greater band gap enhances its effectiveness in electronic and optical devices compared to zinc oxide.

Optical Characteristics and Applications

Zinc oxide exhibits a wide bandgap of 3.37 eV with strong UV light absorption and high transparency in the visible spectrum, making it ideal for applications in UV-blocking coatings and transparent electronics. Zinc sulfide has a slightly narrower bandgap around 3.6 eV, showing efficient photoluminescence and electroluminescence properties, commonly used in optoelectronic devices such as LEDs and phosphors. The optical properties of ZnO and ZnS are crucial for their roles in optical sensors, displays, and photovoltaic cells, with ZnO favored for UV protection and ZnS preferred for luminescent and display technologies.

Chemical Stability and Reactivity

Zinc oxide (ZnO) exhibits high chemical stability under normal atmospheric conditions, resisting moisture and oxygen, which makes it ideal for applications requiring durability and UV protection. In contrast, zinc sulfide (ZnS) is less stable chemically, prone to oxidation and degradation when exposed to air and moisture, limiting its use to controlled environments. The differing reactivity stems from ZnS's sulfide ions, which are more susceptible to chemical changes compared to the oxide ions in ZnO.

Manufacturing Processes

Zinc oxide is primarily produced through the French process, which involves vaporizing metallic zinc in a furnace and allowing it to oxidize, or the American process, which relies on the direct oxidation of zinc ores. In contrast, zinc sulfide is typically synthesized via precipitation methods, reacting zinc salts with sulfide ions in aqueous solutions, or through high-temperature sulfidation of zinc compounds. The manufacturing processes for zinc oxide emphasize thermal oxidation, while zinc sulfide production centers around chemical precipitation or sulfidation techniques.

Industrial and Commercial Uses

Zinc oxide is widely used in industrial applications such as rubber manufacturing, ceramics, and as a white pigment in paints due to its excellent UV protection and antimicrobial properties. Zinc sulfide finds commercial use predominantly in luminescent materials, including phosphorescent paints, X-ray screens, and optical devices because of its efficient light-emitting characteristics. Both compounds serve distinct roles in industries; zinc oxide excels in protective coatings and additives, while zinc sulfide is key in electronic and imaging technologies.

Environmental Impact and Safety

Zinc oxide and zinc sulfide differ significantly in environmental impact and safety profiles. Zinc oxide is widely used in cosmetics and sunscreens due to its low toxicity and biodegradability, but excessive release can lead to aquatic toxicity, affecting fish and algae populations. Zinc sulfide, commonly used in pigments and phosphors, has lower solubility, reducing immediate environmental risks; however, its mining and production processes generate hazardous waste that requires careful management to prevent soil and water contamination.

Cost Factors and Market Availability

Zinc oxide generally has lower production costs due to its simpler extraction and manufacturing processes compared to zinc sulfide, which requires more complex procedures and higher purity raw materials. Market availability favors zinc oxide as it is extensively used in industries such as rubber, cosmetics, and pharmaceuticals, making it more readily accessible and produced in larger volumes globally. Zinc sulfide, primarily used in optical applications and phosphorescent products, remains more specialized and less prevalent in the market, contributing to its relatively higher price and limited availability.

Performance in Pigments and Coatings

Zinc oxide delivers superior UV protection and opacity in pigments and coatings, making it ideal for high-performance applications requiring durability and brightness. Zinc sulfide, while less effective in UV blocking, offers better luminescent properties and is utilized in specialty coatings requiring phosphorescence or transparency. Both compounds enhance corrosion resistance, but zinc oxide remains the preferred choice for industrial coatings due to its cost-effectiveness and chemical stability.

Innovations and Future Trends

Innovations in Zinc Oxide focus on enhancing its photocatalytic and UV-blocking properties through nanostructuring and doping with rare earth elements, driving advances in cosmetics and environmental applications. Zinc Sulfide developments emphasize its potential in optoelectronics and quantum dot technologies, with research targeting improved luminescence efficiency and tunable band gaps for next-generation displays and sensors. Future trends suggest integrating these zinc compounds into multifunctional composites and smart coatings, leveraging their unique electronic and optical traits to pioneer sustainable materials and wearable electronics.

Zinc Oxide vs Zinc Sulfide Infographic

materialdif.com

materialdif.com