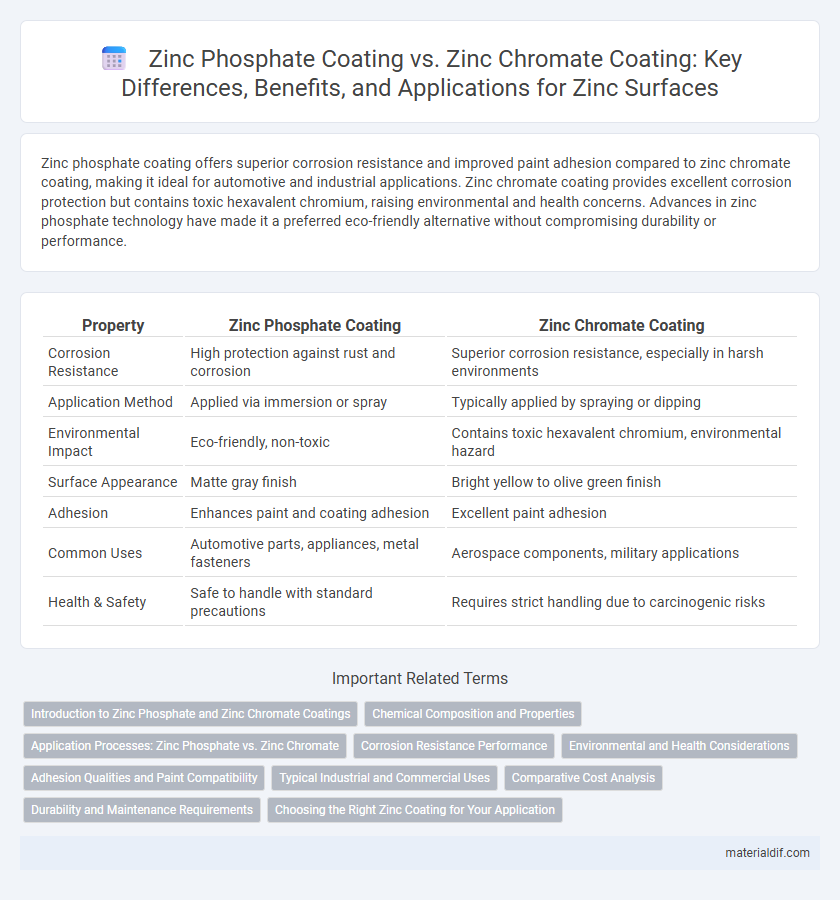

Zinc phosphate coating offers superior corrosion resistance and improved paint adhesion compared to zinc chromate coating, making it ideal for automotive and industrial applications. Zinc chromate coating provides excellent corrosion protection but contains toxic hexavalent chromium, raising environmental and health concerns. Advances in zinc phosphate technology have made it a preferred eco-friendly alternative without compromising durability or performance.

Table of Comparison

| Property | Zinc Phosphate Coating | Zinc Chromate Coating |

|---|---|---|

| Corrosion Resistance | High protection against rust and corrosion | Superior corrosion resistance, especially in harsh environments |

| Application Method | Applied via immersion or spray | Typically applied by spraying or dipping |

| Environmental Impact | Eco-friendly, non-toxic | Contains toxic hexavalent chromium, environmental hazard |

| Surface Appearance | Matte gray finish | Bright yellow to olive green finish |

| Adhesion | Enhances paint and coating adhesion | Excellent paint adhesion |

| Common Uses | Automotive parts, appliances, metal fasteners | Aerospace components, military applications |

| Health & Safety | Safe to handle with standard precautions | Requires strict handling due to carcinogenic risks |

Introduction to Zinc Phosphate and Zinc Chromate Coatings

Zinc phosphate coating provides superior corrosion resistance through the formation of a crystalline phosphate layer that enhances paint adhesion, commonly used in automotive and industrial applications. Zinc chromate coating offers high corrosion protection and acts as a primer, but its use is limited due to the toxicity of hexavalent chromium compounds. Both coatings serve as effective pre-treatment surfaces, yet zinc phosphate is favored for environmental and health safety.

Chemical Composition and Properties

Zinc phosphate coating consists primarily of zinc phosphate crystals combined with binders and water, offering excellent corrosion resistance through a passive barrier and promoting paint adhesion. Zinc chromate coating contains zinc chromate pigments that provide superior anti-corrosion protection due to the hexavalent chromium content, though it poses environmental and health risks. The chemical stability of zinc phosphate coating is higher in alkaline environments, while zinc chromate excels in acidic conditions but requires strict handling measures.

Application Processes: Zinc Phosphate vs. Zinc Chromate

Zinc phosphate coating is primarily applied through a chemical conversion process involving immersion or spray, creating a crystalline phosphate layer that enhances paint adhesion and corrosion resistance. Zinc chromate coating typically involves a chromate conversion process that deposits a protective and corrosion-inhibiting layer on metal surfaces, often applied by dipping or spraying in industrial settings. The zinc phosphate process is favored for automotive and appliance industries due to its environmentally friendly nature, while zinc chromate is historically used in aerospace but is limited by toxicity concerns.

Corrosion Resistance Performance

Zinc phosphate coatings offer superior corrosion resistance by forming a dense, crystalline layer that enhances adhesion and protects against rust and wear in harsh environments. In contrast, zinc chromate coatings provide effective corrosion protection primarily due to their self-healing properties but pose environmental and toxicity concerns due to hexavalent chromium content. Modern applications favor zinc phosphate coatings for sustainable corrosion resistance combined with improved safety profiles.

Environmental and Health Considerations

Zinc phosphate coating offers a more environmentally friendly alternative to zinc chromate coating by eliminating the use of toxic hexavalent chromium compounds, which pose significant health risks such as carcinogenicity and respiratory issues. Zinc phosphate provides effective corrosion resistance while reducing hazardous waste and occupational exposure, aligning with increasingly strict environmental regulations. Its adoption supports safer industrial practices and better worker safety compared to the more hazardous zinc chromate coating.

Adhesion Qualities and Paint Compatibility

Zinc phosphate coatings exhibit superior adhesion qualities compared to zinc chromate coatings, forming a stable crystalline structure that enhances metal surface bonding. This coating type provides excellent paint compatibility, promoting better primer adhesion and reducing the risk of paint delamination. In contrast, zinc chromate coatings offer moderate adhesion and limited compatibility with certain modern paint systems due to their chemical composition.

Typical Industrial and Commercial Uses

Zinc phosphate coating is widely used in automotive and heavy machinery industries for corrosion resistance and paint adhesion on steel surfaces, making it ideal for parts like engine components and structural frameworks. Zinc chromate coating, historically prevalent in aerospace and military applications, provides superior anti-corrosive properties and is favored for aircraft parts and shipbuilding due to its durability. Industrial uses of zinc phosphate emphasize environmentally friendly surface treatment, while zinc chromate remains notable for high-performance protection despite regulatory restrictions due to toxicity concerns.

Comparative Cost Analysis

Zinc phosphate coating generally offers a more cost-effective solution compared to zinc chromate coating due to lower raw material and processing expenses. Zinc chromate coatings, while providing superior corrosion resistance and pigmentation benefits, often involve higher manufacturing costs and stricter environmental regulations that increase overall expenditure. Industrial applications prioritize zinc phosphate coatings when budget constraints are critical, balancing adequate performance with affordability.

Durability and Maintenance Requirements

Zinc phosphate coating offers superior durability compared to zinc chromate, providing enhanced corrosion resistance and longer lifespan in harsh environments. Maintenance requirements for zinc phosphate coatings are generally lower due to their stable and non-toxic properties, reducing the need for frequent reapplications. In contrast, zinc chromate coatings require more careful handling and maintenance because of their toxicity and lower environmental compliance.

Choosing the Right Zinc Coating for Your Application

Zinc phosphate coating offers excellent corrosion resistance and paint adhesion, making it ideal for automotive and industrial applications requiring durable surface treatment. Zinc chromate coating provides superior corrosion protection in harsh environments but poses environmental and health risks due to its toxic chromium content. Selecting the right zinc coating depends on balancing performance needs, regulatory compliance, and environmental safety considerations.

Zinc phosphate coating vs zinc chromate coating Infographic

materialdif.com

materialdif.com