Zinc offers better corrosion resistance and affordability compared to brass, making it ideal for pet products exposed to moisture. Brass provides superior strength and antimicrobial properties, but it is generally heavier and more expensive. Choosing between brass and zinc depends on balancing durability, cost, and specific pet product requirements.

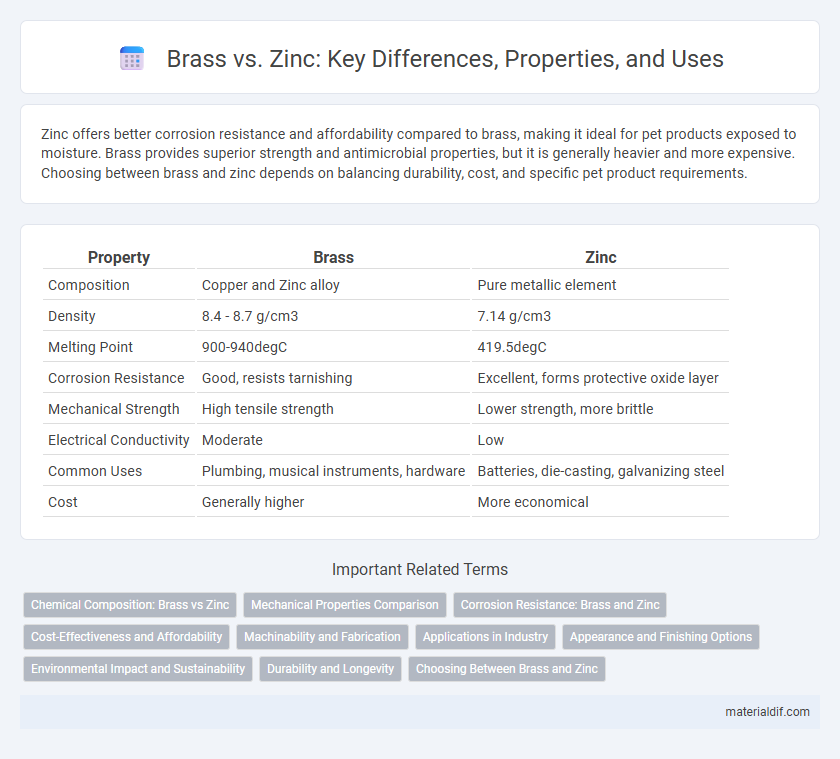

Table of Comparison

| Property | Brass | Zinc |

|---|---|---|

| Composition | Copper and Zinc alloy | Pure metallic element |

| Density | 8.4 - 8.7 g/cm3 | 7.14 g/cm3 |

| Melting Point | 900-940degC | 419.5degC |

| Corrosion Resistance | Good, resists tarnishing | Excellent, forms protective oxide layer |

| Mechanical Strength | High tensile strength | Lower strength, more brittle |

| Electrical Conductivity | Moderate | Low |

| Common Uses | Plumbing, musical instruments, hardware | Batteries, die-casting, galvanizing steel |

| Cost | Generally higher | More economical |

Chemical Composition: Brass vs Zinc

Brass is an alloy primarily composed of copper and zinc, typically containing 55-95% copper and 5-45% zinc, which enhances its strength and corrosion resistance compared to pure zinc. Zinc, a chemical element with atomic number 30, is a bluish-white metal known for its excellent galvanizing properties but lacks the mechanical strength and malleability found in brass alloys. The variation in chemical compositions results in distinct physical and chemical properties, with brass offering greater durability and aesthetic appeal in applications like plumbing and musical instruments.

Mechanical Properties Comparison

Brass exhibits higher tensile strength and better corrosion resistance compared to zinc, making it more suitable for applications demanding durability and environmental exposure. Zinc, while softer with lower tensile strength, offers excellent malleability and impact resistance, often used in die-casting for intricate shapes. Mechanical properties such as yield strength of brass typically range from 200 to 500 MPa, whereas zinc alloys have yield strengths around 150 to 250 MPa, highlighting brass's superior load-bearing capacity.

Corrosion Resistance: Brass and Zinc

Zinc is highly valued for its corrosion resistance, especially in galvanizing steel to prevent rust. Brass, an alloy of copper and zinc, offers enhanced corrosion resistance compared to pure zinc due to the protective patina that forms on its surface. While both materials resist corrosion, zinc performs better in sacrificial protection, whereas brass excels in aesthetic durability and resistance to tarnishing.

Cost-Effectiveness and Affordability

Zinc is significantly more cost-effective than brass due to its lower raw material and production costs, making it an affordable option for large-scale manufacturing. Brass, an alloy primarily composed of copper and zinc, tends to be more expensive because of the high copper content and its intricate processing requirements. For budget-sensitive projects, zinc offers better affordability while still providing adequate durability and corrosion resistance.

Machinability and Fabrication

Brass offers superior machinability compared to zinc due to its uniform composition and lower brittleness, enabling smoother cutting and less tool wear during fabrication. Zinc, while easier to cast because of its low melting point, tends to be more brittle, which can lead to challenges in high-precision machining applications. Fabrication processes favor brass for intricate components requiring tight tolerances, whereas zinc is preferred in die-casting for parts with less demanding dimensional accuracy.

Applications in Industry

Zinc is a critical component in brass alloys, widely used in industries requiring corrosion resistance and electrical conductivity, such as plumbing, automotive, and electrical manufacturing. Brass, which typically contains 60-70% copper and 30-40% zinc, is favored in applications like musical instruments and precision gears due to its malleability and acoustic properties. Zinc alone plays a vital role in galvanization, protecting steel structures in construction and infrastructure from rust and extending their service life.

Appearance and Finishing Options

Brass features a warm, golden-yellow hue that naturally enhances aesthetic appeal and offers diverse finishing options such as polishing, patination, and lacquer coatings for both matte and glossy effects. Zinc presents a more subtle, bluish-gray tone that lends a modern, industrial look and supports various finishing techniques including galvanization, powder coating, and anodizing to improve durability and appearance. Both metals allow customization to meet specific design requirements, but brass is often preferred for decorative uses due to its classic shine, while zinc excels in functional applications with its corrosion-resistant finishes.

Environmental Impact and Sustainability

Brass, an alloy primarily composed of copper and zinc, tends to have a higher environmental impact due to the energy-intensive mining and refining of copper compared to zinc alone. Zinc extraction generally results in lower carbon emissions and less habitat disruption, making it a more sustainable choice for various industrial applications. Recycling zinc consumes significantly less energy and reduces waste, further enhancing its environmental advantages over brass.

Durability and Longevity

Brass, an alloy primarily composed of copper and zinc, exhibits superior durability and corrosion resistance compared to pure zinc, making it ideal for applications requiring extended longevity. Zinc tends to be more prone to oxidation and environmental wear but offers reasonable corrosion resistance in specific conditions, especially when alloyed. The inherent strength and resilience of brass contribute to longer service life in mechanical and architectural uses relative to zinc components.

Choosing Between Brass and Zinc

Choosing between brass and zinc depends on the application's requirements for strength, corrosion resistance, and cost. Brass offers superior corrosion resistance and durability, making it ideal for plumbing fittings and decorative hardware. Zinc, being more cost-effective and easier to cast, is often preferred for die-cast components and automotive parts where moderate strength is sufficient.

Brass vs Zinc Infographic

materialdif.com

materialdif.com