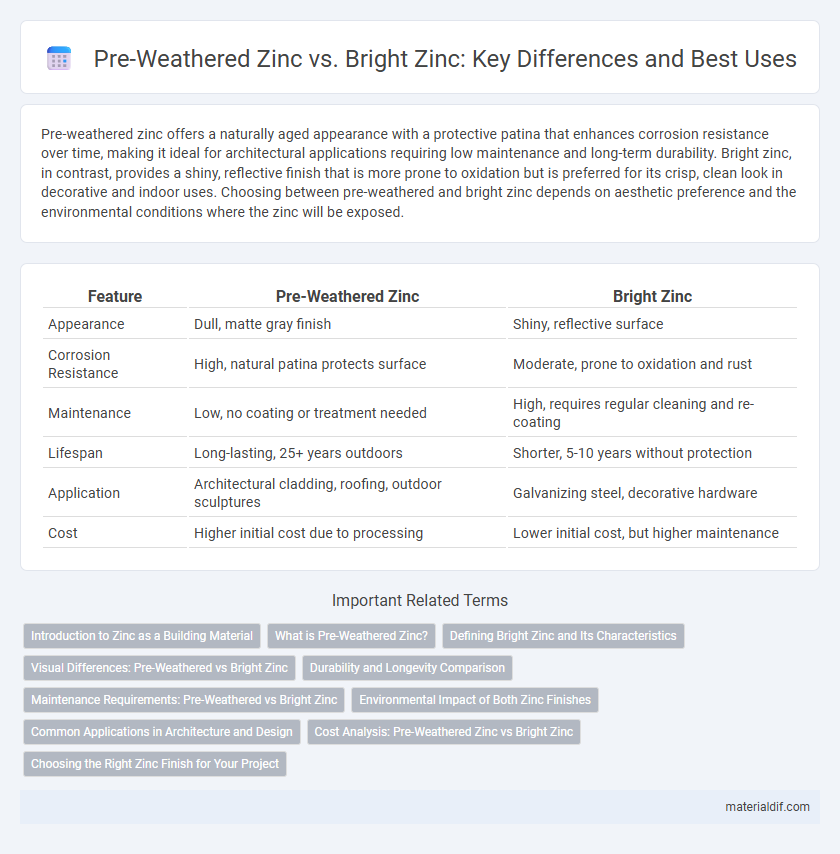

Pre-weathered zinc offers a naturally aged appearance with a protective patina that enhances corrosion resistance over time, making it ideal for architectural applications requiring low maintenance and long-term durability. Bright zinc, in contrast, provides a shiny, reflective finish that is more prone to oxidation but is preferred for its crisp, clean look in decorative and indoor uses. Choosing between pre-weathered and bright zinc depends on aesthetic preference and the environmental conditions where the zinc will be exposed.

Table of Comparison

| Feature | Pre-Weathered Zinc | Bright Zinc |

|---|---|---|

| Appearance | Dull, matte gray finish | Shiny, reflective surface |

| Corrosion Resistance | High, natural patina protects surface | Moderate, prone to oxidation and rust |

| Maintenance | Low, no coating or treatment needed | High, requires regular cleaning and re-coating |

| Lifespan | Long-lasting, 25+ years outdoors | Shorter, 5-10 years without protection |

| Application | Architectural cladding, roofing, outdoor sculptures | Galvanizing steel, decorative hardware |

| Cost | Higher initial cost due to processing | Lower initial cost, but higher maintenance |

Introduction to Zinc as a Building Material

Zinc, a durable and corrosion-resistant metal, is widely used in construction for roofing, cladding, and facades due to its natural ability to develop a protective patina. Pre-weathered zinc offers a consistent aged appearance and reduced maintenance by simulating natural oxidation, while bright zinc provides a shiny, reflective finish requiring more upkeep to prevent weathering effects. Its lightweight nature, flexibility, and recyclability make zinc an environmentally friendly choice in modern building materials.

What is Pre-Weathered Zinc?

Pre-weathered zinc is a type of zinc that has undergone controlled oxidation to develop a stable, protective patina before installation, enhancing its durability and reducing maintenance requirements. This patina mimics natural weathering, preventing unpredictable color changes and corrosion, making it ideal for architectural applications where consistent appearance is crucial. Compared to bright zinc, which is shiny and prone to rapid oxidation and discoloration, pre-weathered zinc offers enhanced longevity and aesthetic stability.

Defining Bright Zinc and Its Characteristics

Bright zinc is a highly reflective, lustrous form of zinc coating frequently used in industrial applications for corrosion resistance and aesthetic appeal. It is characterized by its smooth, shiny surface created through electroplating or hot-dip processes, ensuring enhanced protection against rust and environmental degradation. This zinc type offers superior adhesion to substrates and is preferred for both functional durability and visual finish in metal components.

Visual Differences: Pre-Weathered vs Bright Zinc

Pre-weathered zinc exhibits a matte, textured surface with natural gray patinas that develop over time, providing a rustic, aged appearance ideal for architectural applications seeking an industrial or vintage look. Bright zinc, in contrast, displays a shiny, reflective finish with a smooth, metallic luster that highlights modernity and cleanliness, often used in decorative or high-visibility installations. Visual differences between pre-weathered and bright zinc significantly impact aesthetic choices in construction and design projects.

Durability and Longevity Comparison

Pre-weathered zinc offers superior durability compared to bright zinc due to its natural patina that forms a protective layer, significantly enhancing resistance to corrosion and environmental wear. Bright zinc, lacking this protective coating, is more susceptible to oxidation and requires regular maintenance to maintain its appearance and structural integrity. The longevity of pre-weathered zinc can exceed decades in harsh conditions, making it a preferred choice for architectural and outdoor applications where long-term performance is critical.

Maintenance Requirements: Pre-Weathered vs Bright Zinc

Pre-weathered zinc requires minimal maintenance due to its protective patina that naturally forms and stabilizes over time, reducing corrosion and surface deterioration. Bright zinc, characterized by its shiny and uncoated appearance, demands regular cleaning and potential recoating to prevent oxidation and maintain its aesthetic appeal. The low maintenance nature of pre-weathered zinc makes it ideal for long-term architectural applications where durability and reduced upkeep are essential.

Environmental Impact of Both Zinc Finishes

Pre-weathered zinc offers a significant environmental advantage over bright zinc due to its natural patina that reduces the need for chemical treatments and frequent maintenance. Bright zinc coatings often involve energy-intensive galvanizing processes and may require hazardous post-treatment chemicals, increasing their ecological footprint. The longevity and corrosion resistance of pre-weathered zinc minimize resource consumption and waste generation, making it a more sustainable choice in construction and architectural applications.

Common Applications in Architecture and Design

Pre-weathered zinc is commonly used in architectural cladding, roofing, and facade systems due to its natural patina that provides long-lasting corrosion resistance and minimal maintenance. Bright zinc, with its shiny and reflective surface, is preferred for decorative elements, interior design features, and ornamental details where aesthetic appeal and a polished finish are desired. Both materials are valued for their durability, sustainability, and versatility in contemporary building design.

Cost Analysis: Pre-Weathered Zinc vs Bright Zinc

Pre-weathered zinc offers cost advantages through reduced maintenance expenses and longer service life compared to bright zinc, which typically requires frequent cleaning or coating to prevent corrosion. While the initial price of pre-weathered zinc is higher, the overall lifecycle cost is lower due to its self-protecting patina that eliminates the need for surface treatment. Bright zinc's lower upfront cost can lead to increased expenses over time due to protective coatings and repairs.

Choosing the Right Zinc Finish for Your Project

Pre-weathered zinc offers enhanced durability and a consistent patina, making it ideal for outdoor architectural applications requiring low maintenance and long-lasting aesthetic appeal. Bright zinc, by contrast, provides a shiny, reflective surface suited for indoor projects or decorative elements where a polished look is desired but requires more upkeep to prevent tarnishing. Selecting the appropriate zinc finish depends on exposure conditions, desired visual effect, and maintenance capacity, with pre-weathered zinc favored for longevity and bright zinc for immediate brilliance.

Pre-Weathered Zinc vs Bright Zinc Infographic

materialdif.com

materialdif.com