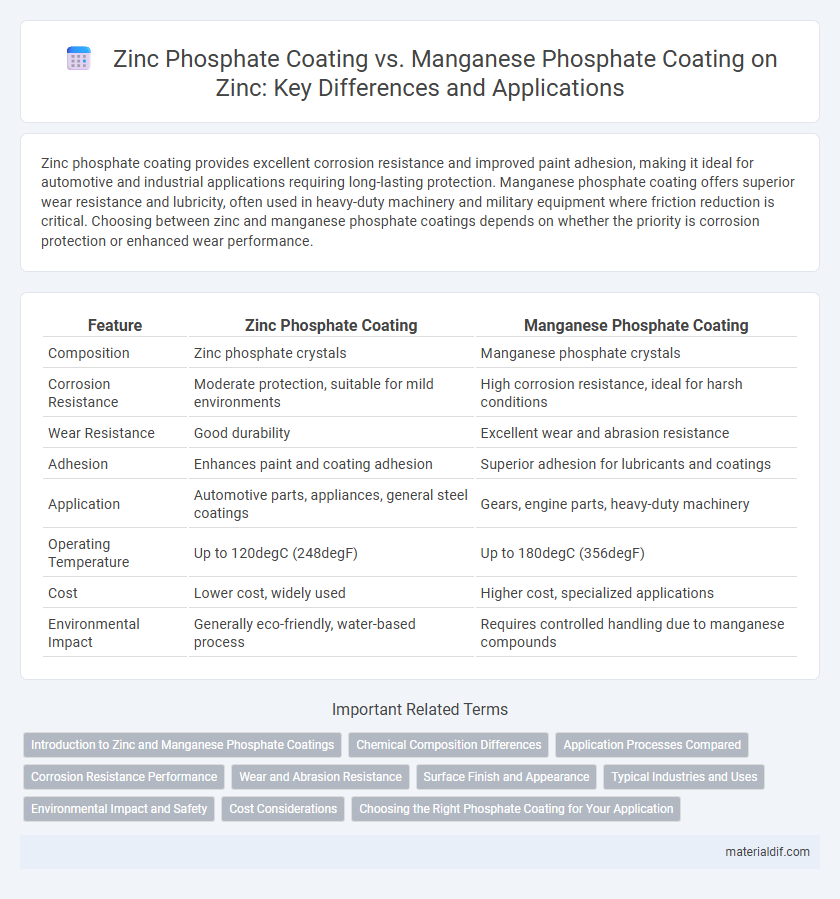

Zinc phosphate coating provides excellent corrosion resistance and improved paint adhesion, making it ideal for automotive and industrial applications requiring long-lasting protection. Manganese phosphate coating offers superior wear resistance and lubricity, often used in heavy-duty machinery and military equipment where friction reduction is critical. Choosing between zinc and manganese phosphate coatings depends on whether the priority is corrosion protection or enhanced wear performance.

Table of Comparison

| Feature | Zinc Phosphate Coating | Manganese Phosphate Coating |

|---|---|---|

| Composition | Zinc phosphate crystals | Manganese phosphate crystals |

| Corrosion Resistance | Moderate protection, suitable for mild environments | High corrosion resistance, ideal for harsh conditions |

| Wear Resistance | Good durability | Excellent wear and abrasion resistance |

| Adhesion | Enhances paint and coating adhesion | Superior adhesion for lubricants and coatings |

| Application | Automotive parts, appliances, general steel coatings | Gears, engine parts, heavy-duty machinery |

| Operating Temperature | Up to 120degC (248degF) | Up to 180degC (356degF) |

| Cost | Lower cost, widely used | Higher cost, specialized applications |

| Environmental Impact | Generally eco-friendly, water-based process | Requires controlled handling due to manganese compounds |

Introduction to Zinc and Manganese Phosphate Coatings

Zinc phosphate coating provides excellent corrosion resistance and lubricity by forming a crystalline phosphate conversion layer on metal surfaces, commonly used in automotive and industrial applications. Manganese phosphate coating offers superior wear resistance and anti-galling properties, often applied in high-friction environments like engine components and firearms. Both coatings enhance surface durability but differ in chemical composition and performance characteristics tailored to specific industrial needs.

Chemical Composition Differences

Zinc phosphate coating primarily consists of zinc orthophosphate crystals formed through the reaction of zinc ions and phosphates, providing excellent corrosion resistance and paint adhesion. Manganese phosphate coating features manganese phosphate minerals combined with iron, resulting in a coarser, denser layer that enhances wear resistance and lubricity. The key chemical difference lies in the metal ion utilized--zinc ions versus manganese ions--which dictates their distinct crystalline structures and protective properties.

Application Processes Compared

Zinc phosphate coating involves a chemical conversion process where steel surfaces are immersed in a phosphating solution, forming a crystalline phosphate layer that enhances corrosion resistance and paint adhesion. In contrast, manganese phosphate coating requires a similar immersion process but operates at higher temperatures and longer durations, producing a denser, more wear-resistant layer ideal for heavy-duty applications. Zinc phosphate coatings are typically used in automotive and appliance industries for primer bases, while manganese phosphate coatings excel in military, automotive engine parts, and industrial machinery due to superior lubrication retention and resistance to metal fatigue.

Corrosion Resistance Performance

Zinc phosphate coating offers excellent corrosion resistance by forming a tightly bonded crystalline layer that inhibits rust on steel surfaces. Manganese phosphate coating provides superior wear resistance and moderate corrosion protection, mainly used for applications requiring both friction reduction and corrosion control. Zinc phosphate coatings generally outperform manganese phosphate in long-term corrosion resistance, especially in humid or saline environments.

Wear and Abrasion Resistance

Zinc phosphate coating offers excellent wear resistance by creating a crystalline layer that enhances paint adhesion and minimizes surface abrasion. Manganese phosphate coating provides superior abrasion resistance and wear protection through a dense, hard phosphate layer ideal for high-friction environments. Both coatings improve durability, but manganese phosphate is preferred for applications demanding extreme wear and abrasion resistance.

Surface Finish and Appearance

Zinc phosphate coating provides a smooth, uniform, and bright surface finish that enhances corrosion resistance and paint adhesion, making it ideal for automotive and appliance industries. Manganese phosphate coating produces a darker, matte, and rougher texture that excels in wear resistance and lubrication retention, frequently used in military and heavy machinery applications. The choice between coatings depends on the desired appearance and protective properties, with zinc phosphate favored for aesthetics and manganese phosphate for durability.

Typical Industries and Uses

Zinc phosphate coating is widely used in automotive manufacturing and appliance production for its excellent corrosion resistance and paint adhesion properties. Manganese phosphate coating is preferred in heavy machinery and military equipment industries due to its high wear resistance and lubrication retention. Both coatings serve distinct roles in protecting metal surfaces, with zinc phosphate emphasizing rust prevention and manganese phosphate focusing on durability under friction.

Environmental Impact and Safety

Zinc phosphate coating offers superior corrosion resistance with a relatively low environmental impact due to its non-toxic nature and eco-friendly disposal methods, making it safer for industrial use. Manganese phosphate coating, although effective for wear resistance, involves higher toxicity levels and generates hazardous waste that requires careful handling to minimize environmental contamination. Choosing zinc phosphate over manganese phosphate enhances workplace safety and reduces ecological risks associated with metal treatment processes.

Cost Considerations

Zinc phosphate coating generally offers a lower cost solution compared to manganese phosphate coating due to its simpler application process and reduced material expenses. Manganese phosphate coating involves higher processing temperatures and longer treatment times, increasing overall operational costs. Cost efficiency of zinc phosphate makes it preferable for large-scale industrial applications requiring corrosion protection at a budget-friendly price point.

Choosing the Right Phosphate Coating for Your Application

Zinc phosphate coating offers superior corrosion resistance and excellent adhesion properties, making it ideal for automotive and industrial applications requiring long-lasting protection. Manganese phosphate coating excels in wear resistance and reduces friction, which is essential for high-stress mechanical parts such as gears and engine components. Selecting the right phosphate coating depends on the specific requirements of corrosion protection, friction reduction, and wear resistance for the intended application.

Zinc Phosphate Coating vs Manganese Phosphate Coating Infographic

materialdif.com

materialdif.com