Die casting offers superior dimensional accuracy and a smoother surface finish compared to sand casting, making it ideal for producing complex zinc parts with tight tolerances. Sand casting, while more cost-effective for small production runs and larger, simpler shapes, results in rougher textures and less precision. Choosing between die casting and sand casting depends on the specific requirements for detail, volume, and budget in zinc manufacturing projects.

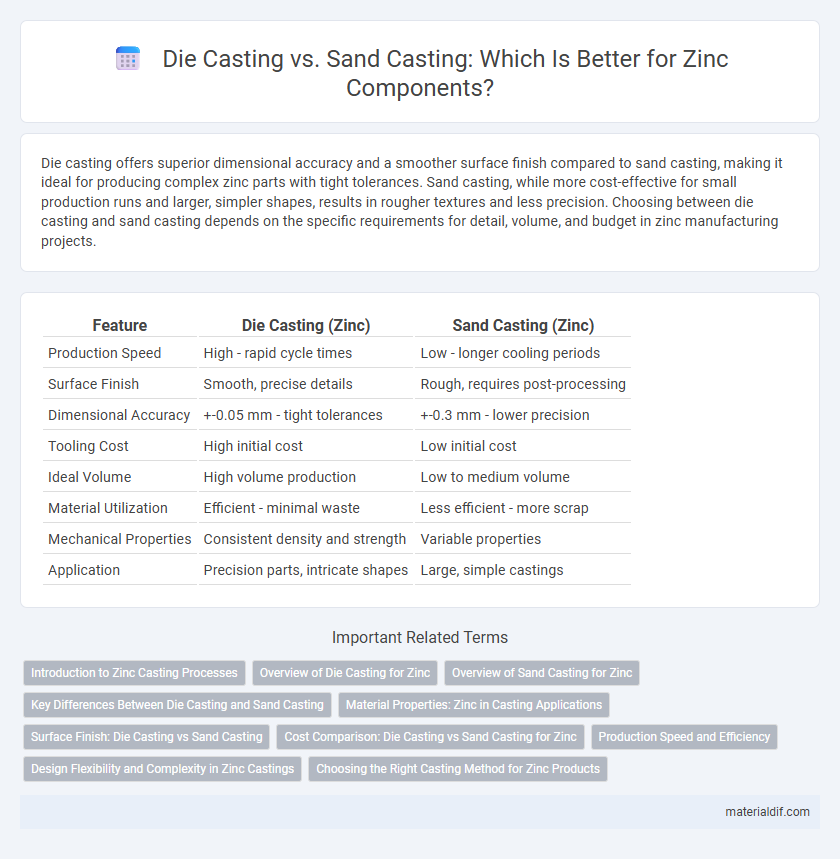

Table of Comparison

| Feature | Die Casting (Zinc) | Sand Casting (Zinc) |

|---|---|---|

| Production Speed | High - rapid cycle times | Low - longer cooling periods |

| Surface Finish | Smooth, precise details | Rough, requires post-processing |

| Dimensional Accuracy | +-0.05 mm - tight tolerances | +-0.3 mm - lower precision |

| Tooling Cost | High initial cost | Low initial cost |

| Ideal Volume | High volume production | Low to medium volume |

| Material Utilization | Efficient - minimal waste | Less efficient - more scrap |

| Mechanical Properties | Consistent density and strength | Variable properties |

| Application | Precision parts, intricate shapes | Large, simple castings |

Introduction to Zinc Casting Processes

Zinc casting processes primarily include die casting and sand casting, each offering distinct advantages based on production requirements. Die casting of zinc enables high precision, rapid production, and excellent surface finish due to its use of reusable steel molds and high-pressure injection. Sand casting, while slower and less precise, allows for greater flexibility with complex shapes and smaller production runs, utilizing sand molds that can accommodate larger design variations.

Overview of Die Casting for Zinc

Die casting for zinc involves injecting molten zinc into precision-machined steel molds under high pressure, enabling the production of components with excellent dimensional accuracy and smooth surface finishes. This process allows for high-volume manufacturing with rapid cycle times, reducing material waste and minimizing post-machining requirements compared to sand casting. Zinc die casting also benefits from the metal's low melting point and excellent fluidity, which ensures complex shapes and thin-walled designs are achievable with good mechanical strength.

Overview of Sand Casting for Zinc

Sand casting for zinc involves creating molds from a mixture of sand and binders that withstand molten zinc's relatively low melting point of approximately 420degC (788degF). This process is cost-effective for producing complex shapes and medium to large-sized parts with moderate precision. Although sand casting generally results in a rougher surface finish and less dimensional accuracy compared to die casting, it offers flexibility in design changes and lower tooling costs.

Key Differences Between Die Casting and Sand Casting

Die casting of zinc offers superior dimensional accuracy and surface finish compared to sand casting, making it ideal for high-volume production with intricate designs. Sand casting provides greater design flexibility and lower tooling costs, suitable for larger parts and smaller production runs. Zinc die casting produces parts with higher mechanical strength and better pressure tightness, whereas sand casting typically results in coarser surface texture and lower precision.

Material Properties: Zinc in Casting Applications

Zinc exhibits excellent corrosion resistance and high ductility, making it ideal for die casting processes that require intricate shapes and smooth surface finishes. In die casting, zinc's low melting point (around 420degC) improves mold longevity and reduces cycle times compared to sand casting, which is more suited for larger, less detailed parts. Sand casting with zinc may result in rougher surfaces and lower dimensional accuracy, limiting its use in precision applications where zinc's mechanical strength and fine grain structure are critical.

Surface Finish: Die Casting vs Sand Casting

Die casting of zinc produces a smoother, more precise surface finish with fine details and minimal post-processing compared to sand casting. Sand casting typically results in a rougher, grainy texture due to the granular sand mold, often requiring additional machining or polishing. The superior surface quality of die casting makes it ideal for components demanding high aesthetic appeal and tight dimensional tolerances.

Cost Comparison: Die Casting vs Sand Casting for Zinc

Die casting zinc generally incurs higher initial tooling costs due to the precision molds required, but it offers lower per-unit costs for large production runs through faster cycle times and reduced labor. Sand casting zinc has lower upfront expenses with flexible mold materials, making it cost-effective for small batches or prototypes despite longer production times and higher labor intensity. Evaluating volume and complexity is crucial, as die casting becomes more economical at scale while sand casting remains advantageous for limited quantities.

Production Speed and Efficiency

Die casting of zinc alloys offers significantly faster production speeds compared to sand casting due to its automated process and rapid cooling times, enabling high-volume output with consistent precision. Efficiency in die casting is enhanced by reduced labor costs and minimal post-processing, whereas sand casting often involves longer mold preparation and finishing stages. The ability of die casting to produce complex shapes with tight tolerances in shorter cycles makes it the preferred method for large-scale zinc component manufacturing.

Design Flexibility and Complexity in Zinc Castings

Die casting of zinc enables the creation of highly complex and intricate designs with tight tolerances, offering superior surface finish and dimensional accuracy compared to sand casting. Zinc sand casting allows for larger, less detailed components but provides greater flexibility for design changes and lower tooling costs. The choice depends on balancing the need for precision and complexity with budget and production volume requirements.

Choosing the Right Casting Method for Zinc Products

Selecting the appropriate casting method for zinc products hinges on factors such as production volume, dimensional accuracy, and surface finish requirements. Die casting, favored for high-volume runs, delivers precise, smooth components with excellent dimensional consistency, ideal for intricate designs. Sand casting offers flexibility and lower tooling costs, making it suitable for large, complex parts or limited production batches where surface finish and tight tolerances are less critical.

Die Casting vs Sand Casting (Zinc) Infographic

materialdif.com

materialdif.com