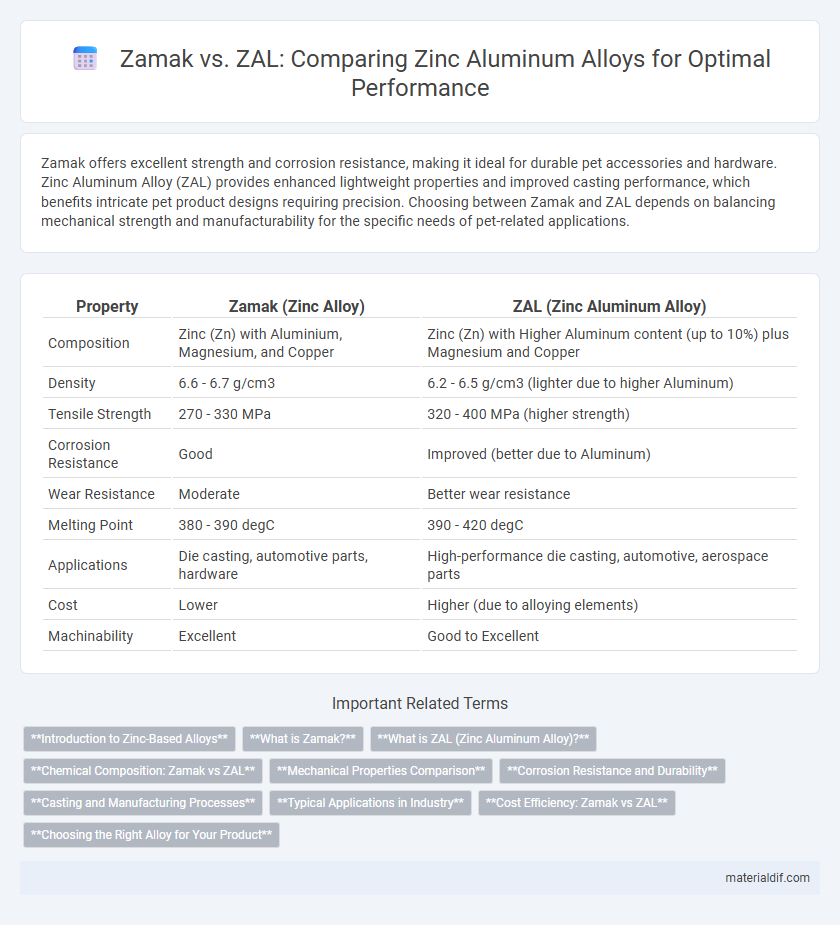

Zamak offers excellent strength and corrosion resistance, making it ideal for durable pet accessories and hardware. Zinc Aluminum Alloy (ZAL) provides enhanced lightweight properties and improved casting performance, which benefits intricate pet product designs requiring precision. Choosing between Zamak and ZAL depends on balancing mechanical strength and manufacturability for the specific needs of pet-related applications.

Table of Comparison

| Property | Zamak (Zinc Alloy) | ZAL (Zinc Aluminum Alloy) |

|---|---|---|

| Composition | Zinc (Zn) with Aluminium, Magnesium, and Copper | Zinc (Zn) with Higher Aluminum content (up to 10%) plus Magnesium and Copper |

| Density | 6.6 - 6.7 g/cm3 | 6.2 - 6.5 g/cm3 (lighter due to higher Aluminum) |

| Tensile Strength | 270 - 330 MPa | 320 - 400 MPa (higher strength) |

| Corrosion Resistance | Good | Improved (better due to Aluminum) |

| Wear Resistance | Moderate | Better wear resistance |

| Melting Point | 380 - 390 degC | 390 - 420 degC |

| Applications | Die casting, automotive parts, hardware | High-performance die casting, automotive, aerospace parts |

| Cost | Lower | Higher (due to alloying elements) |

| Machinability | Excellent | Good to Excellent |

Introduction to Zinc-Based Alloys

Zinc-based alloys such as Zamak and ZAL (Zinc Aluminum Alloy) are widely utilized in industrial applications due to their excellent corrosion resistance and mechanical properties. Zamak is primarily composed of zinc with aluminum, magnesium, and copper, offering superior castability and surface finish, ideal for high-precision die-casting. In contrast, ZAL integrates a higher aluminum content, enhancing strength and heat resistance, making it suitable for structural components requiring durability and dimensional stability.

What is Zamak?

Zamak is a family of zinc-based alloys primarily composed of zinc, aluminum, magnesium, and copper, known for excellent castability, strength, and corrosion resistance. It is widely used in die casting for manufacturing precision components in automotive, electronics, and hardware industries due to its dimensional stability and smooth surface finish. Zamak alloys typically offer superior mechanical properties compared to standard ZAL (Zinc Aluminum Alloy), making them ideal for high-performance applications.

What is ZAL (Zinc Aluminum Alloy)?

ZAL (Zinc Aluminum Alloy) is a specialized type of zinc alloy that incorporates aluminum to enhance strength, corrosion resistance, and thermal stability compared to conventional zinc alloys like Zamak. ZAL typically contains around 4-5% aluminum combined with zinc, resulting in improved mechanical properties ideal for high-stress applications. This alloy offers better wear resistance and dimensional stability, making it suitable for precision components in automotive and industrial manufacturing.

Chemical Composition: Zamak vs ZAL

Zamak alloys primarily consist of 96% zinc combined with aluminum, magnesium, and copper, typically containing 3-4% aluminum which enhances strength and corrosion resistance. ZAL (Zinc Aluminum Alloy) features a higher aluminum content, usually between 8-12%, resulting in improved mechanical properties and increased durability compared to standard Zamak. The elevated aluminum percentage in ZAL alloys significantly influences hardness and heat resistance, making it suitable for demanding industrial applications.

Mechanical Properties Comparison

Zamak alloys typically offer higher tensile strength, ranging from 280 to 380 MPa, while ZAL (Zinc Aluminum Alloy) exhibits enhanced ductility with elongation percentages up to 60%, surpassing Zamak's 10-15%. ZAL alloys demonstrate superior impact resistance and fatigue strength due to their optimized aluminum content, making them more suitable for dynamic load applications. Hardness values of Zamak generally fall between 80-120 HV, whereas ZAL can achieve comparable hardness with better corrosion resistance, contributing to longer component lifespan under mechanical stress.

Corrosion Resistance and Durability

Zamak alloys offer moderate corrosion resistance due to their zinc-rich composition, but they tend to perform less effectively in harsh or marine environments compared to ZAL (Zinc Aluminum Alloy). ZAL alloys incorporate higher aluminum content, significantly enhancing corrosion resistance and extending durability by forming a more stable and protective oxide layer on the surface. This makes ZAL alloys more suitable for applications requiring long-term exposure to moisture and corrosive elements.

Casting and Manufacturing Processes

Zamak and ZAL (Zinc Aluminum Alloy) differ notably in casting and manufacturing processes due to their distinct metallurgical compositions. Zamak alloys, primarily composed of zinc with aluminum, magnesium, and copper, are well-suited for die casting, offering excellent fluidity and dimensional stability ideal for complex, high-precision components. ZAL alloys contain higher aluminum content, resulting in increased strength and corrosion resistance, and they often require modified casting techniques such as gravity casting or low-pressure casting to optimize mechanical properties and surface finish.

Typical Applications in Industry

Zamak alloys are widely used in die-casting for automotive parts, electrical components, and household appliances due to their excellent strength, corrosion resistance, and dimensional stability. Zinc Aluminum Alloy (ZAL) finds typical applications in construction hardware, marine fittings, and industrial machinery, where enhanced wear resistance and improved mechanical properties are essential. Both alloys serve critical roles in manufacturing durable, cost-effective components tailored to specific industrial performance requirements.

Cost Efficiency: Zamak vs ZAL

Zamak alloys typically offer greater cost efficiency due to their lower raw material costs and widespread availability compared to ZAL (Zinc Aluminum Alloy), which contains higher aluminum content and specialized additives that increase production expenses. Zamak's simpler composition enables faster casting cycles and reduces manufacturing costs in high-volume applications. However, ZAL may provide longer tool life and improved mechanical properties, potentially balancing upfront costs with durability in some scenarios.

Choosing the Right Alloy for Your Product

Selecting the right alloy between Zamak and ZAL (Zinc Aluminum Alloy) depends on the specific application requirements such as strength, corrosion resistance, and machinability. Zamak alloys, composed primarily of zinc with aluminum and magnesium, offer excellent dimensional stability and are ideal for intricate die casting, while ZAL alloys provide enhanced corrosion resistance and higher tensile strength due to their increased aluminum content. Evaluating factors like environmental exposure, mechanical stress, and cost efficiency ensures optimal material performance for your product.

Zamak vs ZAL (Zinc Aluminum Alloy) Infographic

materialdif.com

materialdif.com