Mechanical plating with zinc media offers a uniform coating that eliminates hydrogen embrittlement, unlike electroplating which can introduce hydrogen into the metal substrate. Mechanical plating applies zinc particles through impact, providing excellent corrosion resistance and reduced risk of distortion in delicate parts. Electroplating, while precise in controlling thickness, typically requires post-treatment to remove hydrogen and can be less environmentally friendly due to chemical use.

Table of Comparison

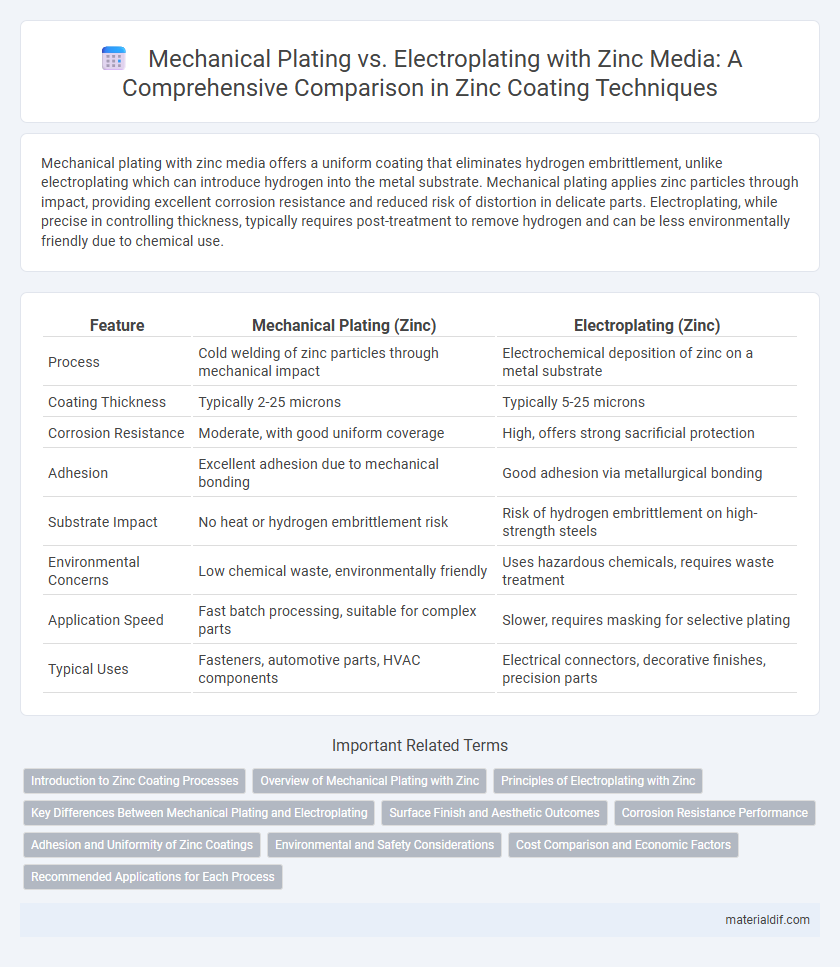

| Feature | Mechanical Plating (Zinc) | Electroplating (Zinc) |

|---|---|---|

| Process | Cold welding of zinc particles through mechanical impact | Electrochemical deposition of zinc on a metal substrate |

| Coating Thickness | Typically 2-25 microns | Typically 5-25 microns |

| Corrosion Resistance | Moderate, with good uniform coverage | High, offers strong sacrificial protection |

| Adhesion | Excellent adhesion due to mechanical bonding | Good adhesion via metallurgical bonding |

| Substrate Impact | No heat or hydrogen embrittlement risk | Risk of hydrogen embrittlement on high-strength steels |

| Environmental Concerns | Low chemical waste, environmentally friendly | Uses hazardous chemicals, requires waste treatment |

| Application Speed | Fast batch processing, suitable for complex parts | Slower, requires masking for selective plating |

| Typical Uses | Fasteners, automotive parts, HVAC components | Electrical connectors, decorative finishes, precision parts |

Introduction to Zinc Coating Processes

Mechanical plating uses zinc media to coat components through tumbling and impact, creating a uniform, non-electrolytic zinc layer that offers excellent corrosion resistance without heat distortion. Electroplating deposits zinc ions onto a conductive surface using an electric current, producing a precise, adherent zinc coating with superior thickness control. Both processes enhance metal durability and corrosion protection, but mechanical plating excels in complex geometries and heat-sensitive parts, while electroplating provides a smoother, more consistent finish.

Overview of Mechanical Plating with Zinc

Mechanical plating with zinc involves applying zinc particles onto a substrate through impact and cold welding without using electrical current, resulting in a uniform, corrosion-resistant coating. This process is ideal for plating complex parts and provides excellent adhesion and ductility, reducing hydrogen embrittlement risks compared to electroplating. Mechanical zinc plating creates a durable layer, often enhanced with passivates or sealers, to improve long-term corrosion protection.

Principles of Electroplating with Zinc

Electroplating with zinc involves the deposition of zinc ions onto a metal substrate through an electrolytic process, where the workpiece acts as the cathode in an electrochemical cell. Zinc ions from the electrolyte solution are reduced and form a uniform, tightly bonded coating that enhances corrosion resistance and surface hardness. This process requires precise control of current density, bath composition, and temperature to achieve optimal coating thickness and adhesion.

Key Differences Between Mechanical Plating and Electroplating

Mechanical plating applies zinc through a cold process using kinetic energy to embed metal particles onto a substrate, resulting in uniform coverage and minimal hydrogen embrittlement risk. Electroplating deposits zinc via an electrical current in a chemical bath, creating a tightly bonded, corrosion-resistant layer but with potential for hydrogen embrittlement and higher environmental impact. Mechanical plating is preferred for complex geometries and improved adhesion without the need for pre-treatment, whereas electroplating offers precise thickness control and superior finish quality.

Surface Finish and Aesthetic Outcomes

Mechanical plating with zinc media produces a uniform, matte surface finish that resists hydrogen embrittlement, ideal for delicate parts requiring consistent corrosion protection. Electroplating with zinc delivers a smoother, shinier, and more aesthetically pleasing finish often favored in decorative applications but may cause hydrogen embrittlement without proper precautions. The choice between mechanical plating and electroplating hinges on the required surface appearance and the mechanical stress tolerance of the substrate.

Corrosion Resistance Performance

Mechanical plating with zinc media offers superior corrosion resistance by creating a uniform, non-porous coating that resists peeling and cracking better than electroplating. Zinc electroplating can provide a thinner, less consistent layer, making it more susceptible to corrosion under harsh environmental conditions. Mechanical plating's enhanced adhesion and even coverage improve long-term protection against rust and corrosion in industrial applications.

Adhesion and Uniformity of Zinc Coatings

Mechanical plating with zinc media offers superior adhesion compared to electroplating due to its cold welding process that creates a strong bond between the zinc particles and the substrate. Uniformity of zinc coatings is enhanced in mechanical plating as the process evenly deposits zinc regardless of part geometry, minimizing variations in thickness. Electroplating, while capable of producing smooth coatings, often faces challenges with adhesion and achieving consistent zinc layer uniformity on complex surfaces.

Environmental and Safety Considerations

Mechanical plating with zinc media eliminates the use of hazardous electrical currents and reduces chemical waste compared to electroplating, which relies on toxic zinc-containing solutions and produces hazardous sludge. Mechanical plating operates at ambient temperatures, minimizing energy consumption and reducing the risk of worker exposure to harmful fumes and acids commonly found in electroplating baths. This process generates less environmental contamination and improves workplace safety, making it a more sustainable and eco-friendly zinc coating method.

Cost Comparison and Economic Factors

Mechanical plating with zinc media generally incurs lower initial equipment costs and reduced energy consumption compared to zinc electroplating, which requires complex electrical setups and higher power usage. Electroplating often demands more expensive chemical baths and stringent waste treatment protocols, raising operational expenses. Economic factors favor mechanical plating for large-scale, cost-sensitive applications due to its simpler process and lower environmental compliance costs.

Recommended Applications for Each Process

Mechanical plating with zinc media is recommended for delicate or small parts requiring uniform coverage without heat or hydrogen embrittlement, such as fasteners, springs, and intricate components in automotive and aerospace industries. Electroplating with zinc is preferred for larger, less heat-sensitive parts that benefit from thicker, more corrosion-resistant coatings, often used in construction, heavy machinery, and industrial equipment. Choosing between mechanical plating and electroplating depends on factors like part size, material sensitivity, required coating thickness, and corrosion resistance needs.

Mechanical plating vs Electroplating (with zinc media) Infographic

materialdif.com

materialdif.com