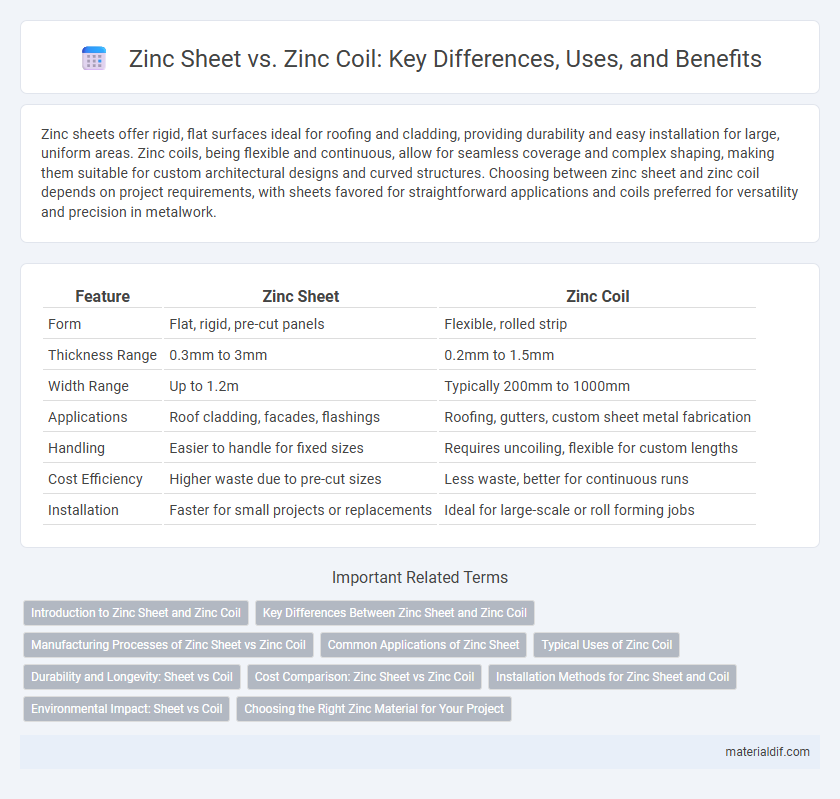

Zinc sheets offer rigid, flat surfaces ideal for roofing and cladding, providing durability and easy installation for large, uniform areas. Zinc coils, being flexible and continuous, allow for seamless coverage and complex shaping, making them suitable for custom architectural designs and curved structures. Choosing between zinc sheet and zinc coil depends on project requirements, with sheets favored for straightforward applications and coils preferred for versatility and precision in metalwork.

Table of Comparison

| Feature | Zinc Sheet | Zinc Coil |

|---|---|---|

| Form | Flat, rigid, pre-cut panels | Flexible, rolled strip |

| Thickness Range | 0.3mm to 3mm | 0.2mm to 1.5mm |

| Width Range | Up to 1.2m | Typically 200mm to 1000mm |

| Applications | Roof cladding, facades, flashings | Roofing, gutters, custom sheet metal fabrication |

| Handling | Easier to handle for fixed sizes | Requires uncoiling, flexible for custom lengths |

| Cost Efficiency | Higher waste due to pre-cut sizes | Less waste, better for continuous runs |

| Installation | Faster for small projects or replacements | Ideal for large-scale or roll forming jobs |

Introduction to Zinc Sheet and Zinc Coil

Zinc sheets and zinc coils are two primary forms of zinc used in construction and manufacturing for corrosion resistance and durability. Zinc sheets are flat, pre-cut pieces offering ease of installation and precision for roofing, cladding, and architectural applications. Zinc coils, supplied in continuous rolls, provide flexibility and efficiency in large-scale projects requiring custom sizing and shaping.

Key Differences Between Zinc Sheet and Zinc Coil

Zinc sheets are flat, rigid metal pieces commonly used for roofing, cladding, and decorative applications, offering precise dimensions and easier handling for smaller projects. Zinc coils consist of zinc metal wound into rolls, providing continuous material ideal for large-scale manufacturing, industrial fabrication, and automated processes. The key differences lie in their form factor, application scope, and flexibility, with sheets favored for detailed work and coils preferred for volume and efficiency.

Manufacturing Processes of Zinc Sheet vs Zinc Coil

Zinc sheets are typically produced by hot rolling or cold rolling zinc ingots into flat, thin plates, ensuring uniform thickness and smooth surfaces for applications like roofing and gutters. Zinc coils undergo a continuous rolling process where molten zinc is cast into thin, flexible coils, facilitating easier transportation and usage in automated fabrication systems for metal forming. The manufacturing process for zinc coils emphasizes high flexibility and consistency for mass production, while zinc sheet production focuses on structural integrity and surface finish.

Common Applications of Zinc Sheet

Zinc sheets are widely used in roofing, cladding, and architectural facades due to their durability, corrosion resistance, and malleability. They are commonly employed in manufacturing gutters, flashings, and decorative elements where precise shaping and ease of installation are essential. Unlike zinc coils, zinc sheets provide uniform thickness and surface quality, making them ideal for visible applications requiring aesthetic appeal and long-term performance.

Typical Uses of Zinc Coil

Zinc coils are commonly used in roofing, cladding, and rainwater systems due to their flexibility and ease of installation on curved and expansive surfaces. They are ideal for structural components, gutters, flashing, and HVAC applications where continuous, seamless metal is essential for water resistance and corrosion protection. In contrast to zinc sheets, zinc coils facilitate manufacturing processes that require custom shapes and sizes, enhancing versatility in architectural and industrial uses.

Durability and Longevity: Sheet vs Coil

Zinc sheets offer superior durability due to their thicker gauge, providing enhanced resistance to corrosion and physical damage compared to zinc coils. Zinc coils, while flexible and easy to handle, are typically thinner, which can reduce their lifespan under harsh environmental conditions. For long-term applications requiring robust protection, zinc sheets are preferred as they maintain structural integrity and resist wear better over time.

Cost Comparison: Zinc Sheet vs Zinc Coil

Zinc sheet generally costs more per unit compared to zinc coil due to its pre-cut dimensions and ease of handling in smaller projects. Zinc coil offers cost savings in large-scale applications by reducing material waste and allowing continuous processing, which lowers labor expenses. Evaluating project size and fabrication requirements is essential to determine the most economical option between zinc sheet and zinc coil.

Installation Methods for Zinc Sheet and Coil

Zinc sheets are typically installed using traditional methods such as soldering, mechanical fastening, or adhesive bonding, making them ideal for detailed metalwork and smaller applications. Zinc coils are often applied through roll forming and continuous bending techniques, allowing for efficient installation over large surfaces with minimal seams. Both forms require proper surface preparation to ensure optimal adhesion and corrosion resistance during installation.

Environmental Impact: Sheet vs Coil

Zinc sheets and zinc coils both offer durable metal solutions with distinct environmental impacts based on their manufacturing and application processes. Zinc sheets typically involve more energy-intensive production due to cutting and finishing, potentially increasing their carbon footprint compared to zinc coils, which are produced as continuous rolls minimizing waste. Both forms are highly recyclable, but zinc coils' efficiency in transportation and reduced scrap material contribute to a lower overall environmental impact in sustainable construction and manufacturing.

Choosing the Right Zinc Material for Your Project

Zinc sheets offer flat, uniform surfaces ideal for precise architectural detailing and corrosion-resistant cladding, while zinc coils provide flexibility and ease of handling for large-scale roofing and gutter applications. Selecting the right zinc material depends on project requirements such as formability, surface finish, and installation method. Consider zinc sheet for more rigid structures and zinc coil when continuous lengths and adaptability are essential to optimize durability and aesthetic appeal.

Zinc Sheet vs Zinc Coil Infographic

materialdif.com

materialdif.com