Cold galvanizing provides a zinc-rich coating that offers long-lasting corrosion resistance through a simple application process, making it ideal for maintenance and touch-up of steel structures. Thermal spraying applies molten zinc onto surfaces, creating a thicker, more durable layer that excels in high-wear industrial environments. Both methods enhance protection against rust, but cold galvanizing is preferred for convenience while thermal spraying delivers superior mechanical strength.

Table of Comparison

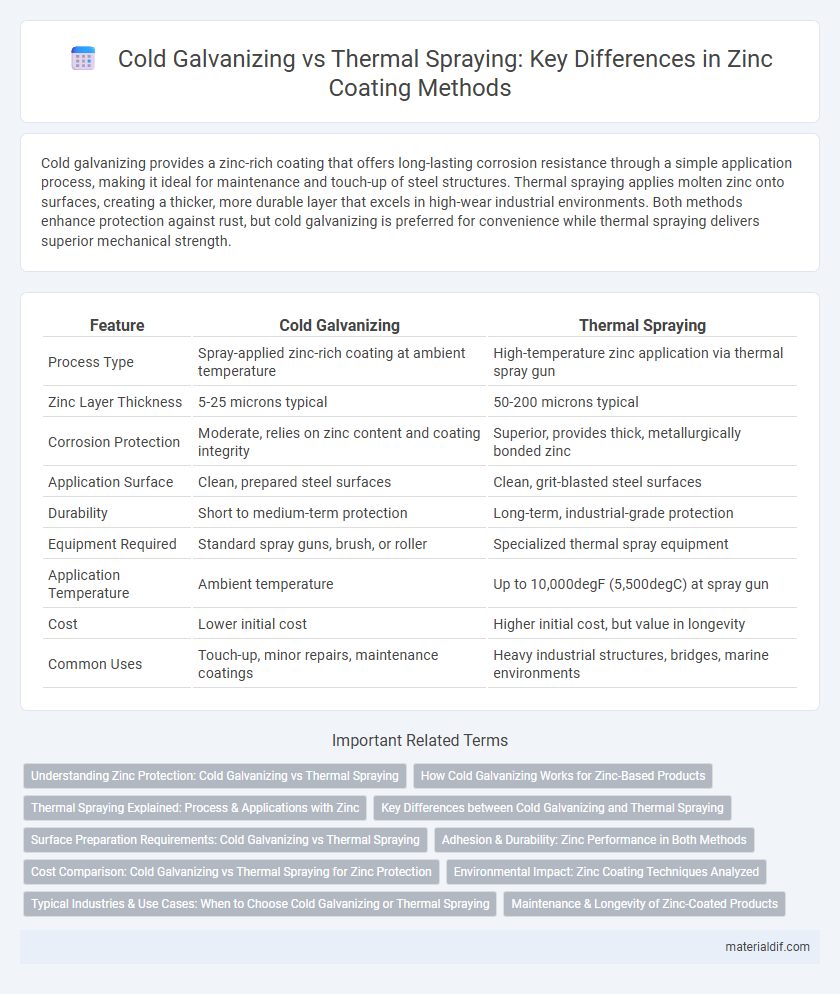

| Feature | Cold Galvanizing | Thermal Spraying |

|---|---|---|

| Process Type | Spray-applied zinc-rich coating at ambient temperature | High-temperature zinc application via thermal spray gun |

| Zinc Layer Thickness | 5-25 microns typical | 50-200 microns typical |

| Corrosion Protection | Moderate, relies on zinc content and coating integrity | Superior, provides thick, metallurgically bonded zinc |

| Application Surface | Clean, prepared steel surfaces | Clean, grit-blasted steel surfaces |

| Durability | Short to medium-term protection | Long-term, industrial-grade protection |

| Equipment Required | Standard spray guns, brush, or roller | Specialized thermal spray equipment |

| Application Temperature | Ambient temperature | Up to 10,000degF (5,500degC) at spray gun |

| Cost | Lower initial cost | Higher initial cost, but value in longevity |

| Common Uses | Touch-up, minor repairs, maintenance coatings | Heavy industrial structures, bridges, marine environments |

Understanding Zinc Protection: Cold Galvanizing vs Thermal Spraying

Cold galvanizing involves applying a zinc-rich paint to provide sacrificial protection against corrosion, ideal for small repairs and maintenance. Thermal spraying uses a high-velocity flame or electric arc to melt zinc wire or powder, creating a thicker, more durable zinc coating suitable for industrial and marine environments. Both methods enhance zinc protection but differ in application technique, coating thickness, and durability, impacting corrosion resistance performance.

How Cold Galvanizing Works for Zinc-Based Products

Cold galvanizing involves applying a zinc-rich paint or coating directly onto steel surfaces, creating a protective barrier against corrosion through a chemical bonding process. The high zinc content in the coating provides sacrificial protection by corroding preferentially to the underlying metal, ensuring long-lasting durability for zinc-based products. This method is efficient for maintenance and repair, offering an easy-to-apply alternative to thermal spraying without requiring high temperatures or specialized equipment.

Thermal Spraying Explained: Process & Applications with Zinc

Thermal spraying with zinc involves melting zinc wire or powder and propelling it onto surfaces to form a corrosion-resistant coating, offering superior adhesion and uniform coverage compared to cold galvanizing. This process is widely used in industrial applications such as bridges, pipelines, and marine structures due to its durability and ability to protect steel from rust and environmental degradation. Thermal spraying offers precise control over coating thickness and composition, making it more effective for long-term zinc protection than cold galvanizing, which relies on zinc-rich paint applied at ambient temperatures.

Key Differences between Cold Galvanizing and Thermal Spraying

Cold galvanizing involves applying a zinc-rich paint to protect steel surfaces by providing sacrificial corrosion resistance, while thermal spraying deposits molten zinc particles to create a thicker, more durable coating. Cold galvanizing offers ease of application and touch-up in the field, but thermal spraying delivers superior adhesion, thickness control, and longer-lasting protection in harsh environments. The choice between cold galvanizing and thermal spraying depends on factors like coating thickness requirements, environmental exposure, and budget constraints.

Surface Preparation Requirements: Cold Galvanizing vs Thermal Spraying

Cold galvanizing requires thorough surface cleaning, including removal of rust, oil, and dirt to ensure proper zinc adhesion, typically achieved through abrasive blasting or wire brushing. Thermal spraying demands more rigorous surface preparation such as abrasive blasting to create a rough profile that enhances mechanical bond strength between the zinc coating and substrate. Both methods emphasize contaminant-free surfaces, but thermal spraying's higher temperatures and stronger adhesion necessitate stricter adherence to surface cleanliness and texture standards.

Adhesion & Durability: Zinc Performance in Both Methods

Cold galvanizing using zinc-rich paints ensures strong adhesion through chemical bonding with the substrate, providing a durable protective layer against corrosion. Thermal spraying applies molten zinc particles that mechanically bond to the surface, offering enhanced abrasion resistance and a more uniform coating thickness. Both methods deliver excellent zinc performance, with cold galvanizing excelling in paint compatibility and thermal spraying in long-term durability under harsh environmental conditions.

Cost Comparison: Cold Galvanizing vs Thermal Spraying for Zinc Protection

Cold galvanizing typically offers a lower initial cost compared to thermal spraying due to simpler application processes and minimal equipment requirements. Thermal spraying, while more expensive upfront, provides thicker, more durable zinc coatings that can extend service life and reduce maintenance costs over time. Evaluating total lifecycle expenses reveals that thermal spraying may offer better long-term value for high-wear environments despite its higher application cost.

Environmental Impact: Zinc Coating Techniques Analyzed

Cold galvanizing uses zinc-rich paints that emit fewer volatile organic compounds (VOCs) and consume less energy compared to thermal spraying, resulting in a lower carbon footprint. Thermal spraying, though providing thicker and more durable zinc layers, generates more particulate emissions and requires higher energy input due to elevated operating temperatures. Both techniques contribute to corrosion resistance, but cold galvanizing is generally preferred for environmentally sensitive projects due to its reduced ecological impact and simpler application process.

Typical Industries & Use Cases: When to Choose Cold Galvanizing or Thermal Spraying

Cold galvanizing is typically chosen in industries requiring corrosion protection of steel structures with minimal equipment needs, such as construction, automotive repair, and maintenance of agricultural machinery, due to its ease of application and suitability for small-scale or on-site jobs. Thermal spraying is preferred in heavy industries like aerospace, power plants, and offshore oil rigs where thick, durable coatings are necessary to withstand extreme environmental conditions and mechanical stress. Choosing between cold galvanizing and thermal spraying hinges on factors like required coating thickness, environmental exposure, application scale, and corrosion resistance longevity.

Maintenance & Longevity of Zinc-Coated Products

Cold galvanizing provides a uniform zinc-rich protective layer that enhances corrosion resistance and requires minimal maintenance, making it ideal for touch-ups and smaller repairs. Thermal spraying offers a thicker, more durable zinc coating suited for harsh environments, extending the lifespan of steel structures with less frequent maintenance needs. Both methods improve longevity, but thermal spraying generally delivers superior abrasion resistance and longer intervals between maintenance cycles.

Cold Galvanizing vs Thermal Spraying Infographic

materialdif.com

materialdif.com