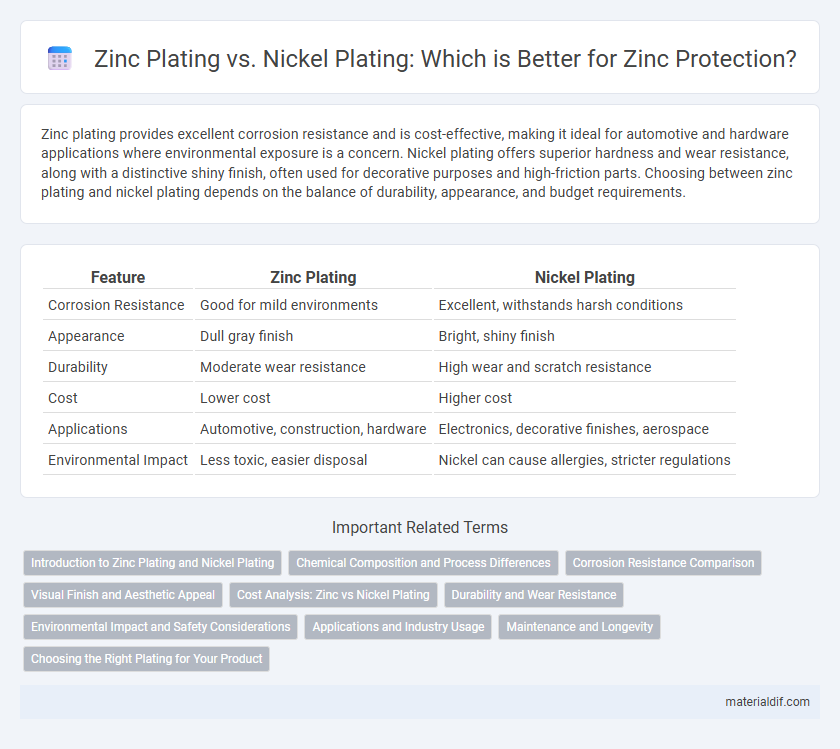

Zinc plating provides excellent corrosion resistance and is cost-effective, making it ideal for automotive and hardware applications where environmental exposure is a concern. Nickel plating offers superior hardness and wear resistance, along with a distinctive shiny finish, often used for decorative purposes and high-friction parts. Choosing between zinc plating and nickel plating depends on the balance of durability, appearance, and budget requirements.

Table of Comparison

| Feature | Zinc Plating | Nickel Plating |

|---|---|---|

| Corrosion Resistance | Good for mild environments | Excellent, withstands harsh conditions |

| Appearance | Dull gray finish | Bright, shiny finish |

| Durability | Moderate wear resistance | High wear and scratch resistance |

| Cost | Lower cost | Higher cost |

| Applications | Automotive, construction, hardware | Electronics, decorative finishes, aerospace |

| Environmental Impact | Less toxic, easier disposal | Nickel can cause allergies, stricter regulations |

Introduction to Zinc Plating and Nickel Plating

Zinc plating provides excellent corrosion resistance by creating a protective zinc layer on metal surfaces, commonly used in automotive and construction industries. Nickel plating offers superior hardness and wear resistance, enhancing both the durability and aesthetic appeal of components in electronics and decorative applications. Both processes involve electrochemical deposition, but zinc plating excels in rust prevention while nickel plating is preferred for enhanced surface toughness and luster.

Chemical Composition and Process Differences

Zinc plating primarily involves the application of a zinc layer, typically using a zinc electroplating process, where zinc ions are deposited onto the metal surface to provide corrosion resistance. Nickel plating uses a nickel layer deposited through electrochemical processes, often involving nickel sulfate or nickel chloride baths, resulting in a harder, more wear-resistant coating. Chemically, zinc coatings offer galvanic protection by sacrificial corrosion, whereas nickel plating provides barrier protection due to its dense, corrosion-resistant metal structure.

Corrosion Resistance Comparison

Zinc plating provides excellent corrosion resistance by forming a protective zinc oxide layer that prevents rust, especially in outdoor and marine environments. Nickel plating offers superior corrosion resistance in harsh chemical conditions and provides a harder, more wear-resistant surface. Selecting between zinc and nickel plating depends on the specific environmental exposure and durability requirements of the application.

Visual Finish and Aesthetic Appeal

Zinc plating offers a bright, silvery finish that provides excellent corrosion resistance and a clean, industrial look favored in automotive and hardware applications. Nickel plating delivers a smoother, more reflective surface with a warmer tone, often chosen for decorative purposes due to its enhanced luster and durability. When prioritizing visual finish and aesthetic appeal, nickel plating typically outperforms zinc plating by providing a more polished and sophisticated appearance.

Cost Analysis: Zinc vs Nickel Plating

Zinc plating offers a cost-effective solution compared to nickel plating, with zinc processes typically costing 30-50% less due to lower raw material and processing expenses. Nickel plating, while more expensive, provides superior corrosion resistance and a more durable finish, justifying higher costs in high-performance applications. The choice between zinc and nickel plating hinges on budget constraints and required coating longevity, where zinc suits economical, lighter-duty uses and nickel fits premium, heavy-duty needs.

Durability and Wear Resistance

Zinc plating offers excellent corrosion resistance and is highly effective for protecting steel from rust, making it durable in outdoor and humid environments. Nickel plating provides superior wear resistance and hardness, ideal for applications involving friction and frequent handling. Combining zinc's corrosion protection with nickel's wear resistance results in optimized longevity for metal components exposed to both environmental and mechanical stresses.

Environmental Impact and Safety Considerations

Zinc plating offers superior corrosion resistance with lower environmental toxicity due to its use of fewer hazardous chemicals compared to nickel plating, which involves toxic compounds like nickel salts that pose significant health risks. The disposal and recycling processes for zinc plating waste are generally safer and more sustainable, minimizing soil and water contamination. Workplace safety is enhanced with zinc plating as it releases fewer harmful fumes, whereas nickel plating requires stringent protective measures to prevent skin sensitization and respiratory issues.

Applications and Industry Usage

Zinc plating excels in automotive and construction industries due to its excellent corrosion resistance and cost-effectiveness for protecting steel components. Nickel plating is preferred in electronics and aerospace sectors for its superior hardness, wear resistance, and aesthetic appeal on precision parts. Both coatings enhance durability, but zinc plating is dominant in large-scale industrial applications, while nickel plating suits high-performance and decorative purposes.

Maintenance and Longevity

Zinc plating offers excellent corrosion resistance with minimal maintenance, making it ideal for outdoor or industrial environments exposed to moisture. Nickel plating provides superior durability and wear resistance, extending the lifespan of components in high-friction applications while requiring occasional polishing to maintain its appearance. Choosing between zinc and nickel plating depends on balancing long-term protection needs with maintenance frequency and environmental conditions.

Choosing the Right Plating for Your Product

Zinc plating offers excellent corrosion resistance and cost-effectiveness, making it ideal for automotive and construction applications where exposure to moisture is common. Nickel plating provides superior hardness, wear resistance, and a bright finish, suitable for decorative items and high-friction components like tools and machinery parts. Selecting the right plating depends on environmental conditions, durability requirements, and budget constraints specific to your product's intended use.

Zinc Plating vs Nickel Plating Infographic

materialdif.com

materialdif.com