Zinc foil offers superior malleability and can be easily shaped around complex surfaces, making it ideal for applications requiring precise coverage. Zinc tape provides strong adhesive properties for quick installation and is best suited for repairs or projects needing a secure, long-lasting bond. Both materials offer excellent corrosion resistance and conductive benefits, but choice depends on the specific demands of flexibility versus adhesive strength.

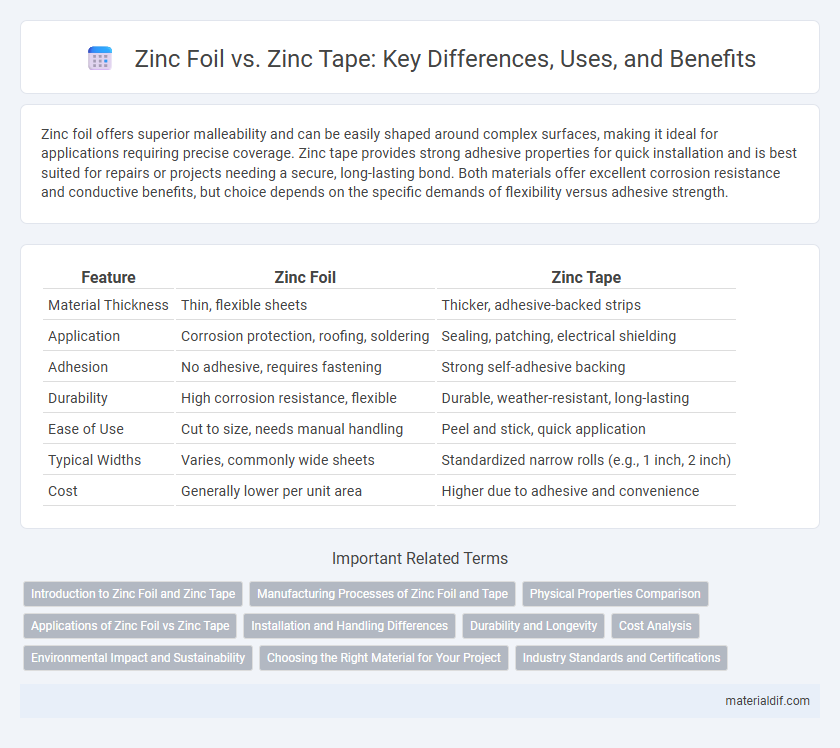

Table of Comparison

| Feature | Zinc Foil | Zinc Tape |

|---|---|---|

| Material Thickness | Thin, flexible sheets | Thicker, adhesive-backed strips |

| Application | Corrosion protection, roofing, soldering | Sealing, patching, electrical shielding |

| Adhesion | No adhesive, requires fastening | Strong self-adhesive backing |

| Durability | High corrosion resistance, flexible | Durable, weather-resistant, long-lasting |

| Ease of Use | Cut to size, needs manual handling | Peel and stick, quick application |

| Typical Widths | Varies, commonly wide sheets | Standardized narrow rolls (e.g., 1 inch, 2 inch) |

| Cost | Generally lower per unit area | Higher due to adhesive and convenience |

Introduction to Zinc Foil and Zinc Tape

Zinc foil and zinc tape are both thin sheets of pure zinc used for corrosion protection, electrical grounding, and artistic applications, but differ primarily in form and application ease. Zinc foil is a flexible, malleable metal sheet typically available in rolls and suited for wrapping and shielding purposes, while zinc tape features an adhesive backing for quick surface adherence without additional fastening. Their density of 7.14 g/cm3 and natural corrosion resistance make them ideal for environments requiring durable, long-lasting zinc coverage.

Manufacturing Processes of Zinc Foil and Tape

Zinc foil is produced through a rolling process where zinc ingots are repeatedly passed through rollers to achieve thin, consistent sheets, while zinc tape is manufactured by laminating a zinc foil layer onto an adhesive backing for flexibility and ease of application. The foil's uniform thickness is controlled by precision rolling mills, ensuring high purity and mechanical strength, whereas zinc tape undergoes additional coating and slitting processes to add adhesive properties and optimal width. Both products are subject to quality control tests such as thickness measurement and adhesion tests to meet industrial standards for corrosion resistance and conductivity.

Physical Properties Comparison

Zinc foil exhibits higher malleability and thinner thickness, typically ranging from 0.02 mm to 0.1 mm, making it ideal for precise wrapping and detailed applications. Zinc tape, often thicker around 0.15 mm to 0.25 mm, combines durability with adhesive backing, providing enhanced resistance to tearing and superior conformability on irregular surfaces. Both materials showcase excellent corrosion resistance and conductivity, but zinc foil excels in flexibility while zinc tape offers practicality in installation.

Applications of Zinc Foil vs Zinc Tape

Zinc foil is widely used in applications requiring precise malleability and corrosion resistance, such as in roofing, flashing, and battery electrodes. Zinc tape offers strong adhesion and flexibility, making it ideal for electrical insulation, shielding, and repair tasks on pipes and ducts. Both materials provide effective corrosion protection but differ primarily in their application methods and surface bonding strengths.

Installation and Handling Differences

Zinc foil offers flexibility and ease of cutting, making it ideal for intricate or detailed applications that require precise fitting, while zinc tape provides a strong adhesive backing for quick, secure installation on various surfaces. Handling zinc foil often requires care to prevent tearing or creasing, whereas zinc tape's adhesive layer simplifies application but may limit repositioning once applied. Installation time with zinc tape tends to be faster due to its peel-and-stick nature, contrasting with zinc foil, which may require additional tools or adhesives for mounting.

Durability and Longevity

Zinc foil offers superior durability and longevity compared to zinc tape due to its thicker gauge and resistance to tearing, making it ideal for high-stress applications and prolonged exposure to environmental factors. Zinc tape, while more flexible and easier to apply, has a thinner composition that can degrade faster under UV radiation and mechanical wear. For projects requiring long-term corrosion protection and structural integrity, zinc foil is the preferred option.

Cost Analysis

Zinc foil generally costs more upfront than zinc tape due to its thicker composition and higher material quality, which offers enhanced durability for long-term applications. Zinc tape provides a more affordable and flexible solution with easier installation but may require more frequent replacement, increasing overall maintenance expenses. When evaluating cost-effectiveness, the initial investment versus longevity and application requirements should guide the decision between zinc foil and zinc tape.

Environmental Impact and Sustainability

Zinc foil and zinc tape differ notably in environmental impact and sustainability; zinc foil, being thinner and lightweight, results in less raw material usage and reduced energy consumption during production compared to thicker zinc tape. Both materials are recyclable and corrosion-resistant, but zinc foil's minimal waste generation aligns better with sustainable manufacturing practices. Choosing zinc foil supports eco-friendly applications by optimizing material efficiency while maintaining zinc's natural, non-toxic properties.

Choosing the Right Material for Your Project

When selecting between zinc foil and zinc tape, consider the project's surface complexity and required adhesion strength. Zinc foil offers superior malleability for intricate shaping and corrosion resistance, making it ideal for detailed applications like roofing or art restoration. Zinc tape, featuring a pressure-sensitive adhesive backing, provides quick installation and strong bonding on flat or slightly curved surfaces, suitable for electrical shielding or minor repairs.

Industry Standards and Certifications

Zinc foil and zinc tape both comply with key industry standards such as ASTM B6 for zinc sheet and ASTM D1000 for pressure-sensitive tapes, ensuring material quality and performance reliability. Zinc foil typically adheres to higher purity requirements, often exceeding 99.9% zinc content, making it ideal for applications demanding superior corrosion resistance and uniform conductivity. Zinc tape incorporates stringent adhesive certifications like UL 723 for flame retardancy, meeting safety and environmental regulations applicable in electrical and construction industries.

Zinc Foil vs Zinc Tape Infographic

materialdif.com

materialdif.com