ZAM coating offers superior corrosion resistance compared to standard zinc coating due to its unique alloy composition that includes aluminum and magnesium, enhancing durability in harsh environments. This advanced coating provides longer-lasting protection for steel surfaces, reducing maintenance and replacement costs. Its enhanced barrier properties make ZAM coating an ideal choice for applications requiring extended lifespan and reliability in corrosive conditions.

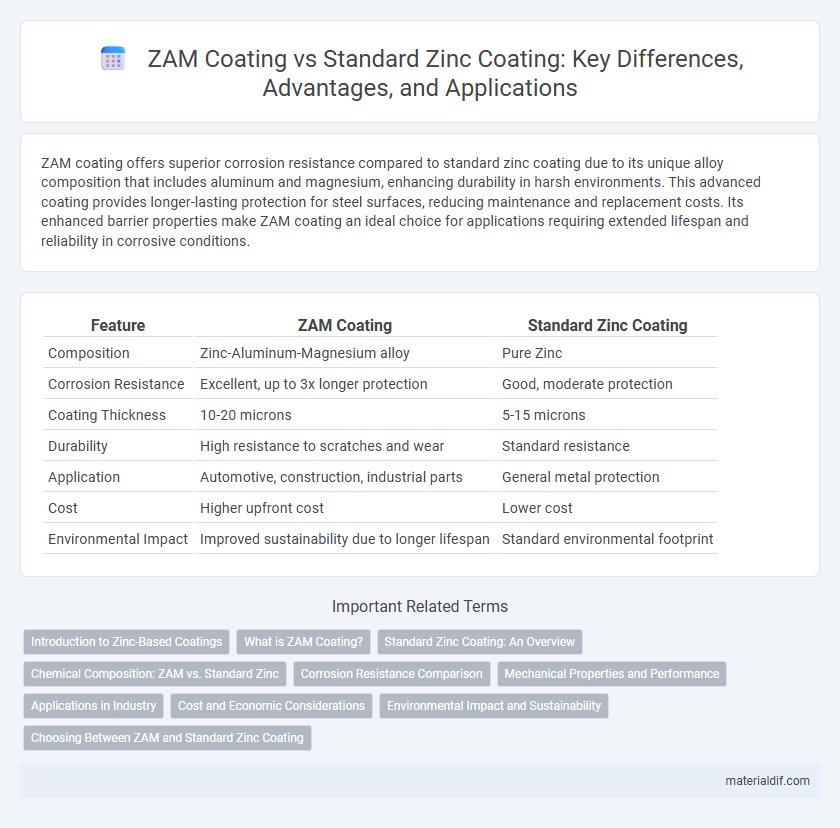

Table of Comparison

| Feature | ZAM Coating | Standard Zinc Coating |

|---|---|---|

| Composition | Zinc-Aluminum-Magnesium alloy | Pure Zinc |

| Corrosion Resistance | Excellent, up to 3x longer protection | Good, moderate protection |

| Coating Thickness | 10-20 microns | 5-15 microns |

| Durability | High resistance to scratches and wear | Standard resistance |

| Application | Automotive, construction, industrial parts | General metal protection |

| Cost | Higher upfront cost | Lower cost |

| Environmental Impact | Improved sustainability due to longer lifespan | Standard environmental footprint |

Introduction to Zinc-Based Coatings

ZAM coating is a zinc-aluminum-magnesium alloy that offers superior corrosion resistance compared to standard zinc coating by forming a dense, protective barrier on steel surfaces. This advanced zinc-based coating provides enhanced durability in harsh environments, significantly extending the lifespan of coated materials. Standard zinc coatings rely primarily on sacrificial protection, while ZAM's alloy composition improves resistance to rust and wear without compromising flexibility.

What is ZAM Coating?

ZAM coating is a zinc-aluminum-magnesium alloy coating designed to enhance corrosion resistance beyond standard zinc coatings. It typically consists of approximately 95% zinc, 3.5% aluminum, and 1.5% magnesium, which forms a more durable and longer-lasting protective layer on metal surfaces. Compared to conventional zinc coatings, ZAM provides superior adhesion, increased protection against rust, and improved performance in harsh environments.

Standard Zinc Coating: An Overview

Standard zinc coating provides reliable corrosion protection by forming a passive layer that prevents rust on steel surfaces. This type of coating typically involves hot-dip galvanizing, where steel is immersed in molten zinc, creating a durable, uniform barrier. Its widespread use across construction and automotive industries demonstrates its effectiveness and cost-efficiency compared to advanced coatings like ZAM.

Chemical Composition: ZAM vs. Standard Zinc

ZAM coating consists primarily of zinc, aluminum (around 3%), and magnesium (approximately 3%), offering enhanced corrosion resistance compared to standard zinc coatings, which are predominantly pure zinc. The added aluminum in ZAM forms a denser, more protective oxide layer, while magnesium improves the coating's adherence and durability. Standard zinc coatings lack these alloying elements, resulting in lower performance in aggressive environments.

Corrosion Resistance Comparison

ZAM coating, an alloy-based zinc coating comprising zinc, aluminum, and magnesium, offers superior corrosion resistance compared to standard zinc coatings due to its enhanced barrier protection and self-healing properties. Studies show that ZAM coatings can extend the lifespan of metal substrates by up to three times under corrosive environments, outperforming traditional pure zinc coatings. The presence of aluminum and magnesium in ZAM creates a denser, more durable protective layer that significantly delays rust formation and corrosion progression.

Mechanical Properties and Performance

ZAM coating outperforms standard zinc coating with enhanced mechanical properties such as superior hardness, abrasion resistance, and impact strength, making it ideal for heavy-duty applications. Its alloy composition, including aluminum, magnesium, and zinc, provides increased corrosion resistance and longer service life compared to traditional zinc coatings. The improved adhesion and flexibility of ZAM coating reduce cracking and wear under mechanical stress, ensuring better durability in demanding environments.

Applications in Industry

ZAM coating offers superior corrosion resistance and durability compared to standard zinc coating, making it ideal for automotive, construction, and agricultural equipment industries. Its aluminum-rich composition provides enhanced protection in harsh environments, reducing maintenance costs and extending service life. Standard zinc coating remains suitable for less demanding applications where basic rust prevention is adequate.

Cost and Economic Considerations

ZAM coating offers a cost-effective alternative to standard zinc coating by providing superior corrosion resistance with a lower zinc content, reducing material expenses and extending maintenance intervals. Although the initial price of ZAM coatings may be slightly higher, the overall lifecycle cost benefits result in significant economic savings for infrastructure and construction projects. Choosing ZAM coating enhances durability while optimizing budget allocation through reduced repair frequency and longer service life.

Environmental Impact and Sustainability

ZAM coating, consisting of zinc, aluminum, and magnesium, offers superior corrosion resistance compared to standard zinc coating, extending the lifespan of steel products and reducing the need for frequent replacement. This enhanced durability leads to lower resource consumption and waste generation, contributing to a more sustainable lifecycle. Standard zinc coating, while effective for corrosion protection, typically requires more frequent maintenance and recoating, resulting in higher environmental impact over time.

Choosing Between ZAM and Standard Zinc Coating

ZAM coating, composed of zinc, aluminum, and magnesium, offers superior corrosion resistance and longer lifespan compared to standard zinc coating, which relies solely on zinc for protection. For environments with high humidity or salt exposure, ZAM coating is ideal due to its enhanced ability to prevent rust and degradation. Standard zinc coating remains a cost-effective choice for less aggressive conditions, balancing protection and budget considerations.

ZAM Coating vs Standard Zinc Coating Infographic

materialdif.com

materialdif.com