Sealed zinc offers superior corrosion resistance by preventing exposure to moisture and air, which significantly extends its durability compared to unsealed zinc. Unsealed zinc may develop a patina or oxidize over time, reducing its protective qualities and potentially leading to material degradation. Choosing sealed zinc is essential for applications requiring long-term protection and maintaining structural integrity.

Table of Comparison

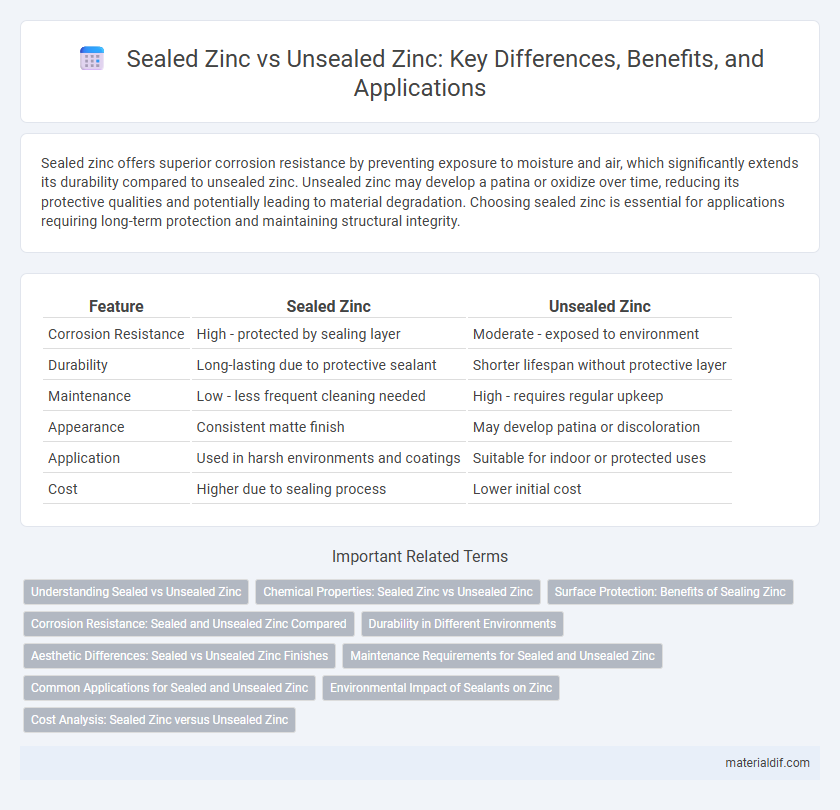

| Feature | Sealed Zinc | Unsealed Zinc |

|---|---|---|

| Corrosion Resistance | High - protected by sealing layer | Moderate - exposed to environment |

| Durability | Long-lasting due to protective sealant | Shorter lifespan without protective layer |

| Maintenance | Low - less frequent cleaning needed | High - requires regular upkeep |

| Appearance | Consistent matte finish | May develop patina or discoloration |

| Application | Used in harsh environments and coatings | Suitable for indoor or protected uses |

| Cost | Higher due to sealing process | Lower initial cost |

Understanding Sealed vs Unsealed Zinc

Sealed zinc provides enhanced corrosion resistance by preventing moisture and contaminants from reaching the metal surface, making it ideal for outdoor and marine applications. Unsealed zinc allows for a natural oxidation layer that can offer some protection but is more susceptible to environmental damage and wear over time. Choosing between sealed and unsealed zinc depends on the required durability and exposure conditions, with sealed zinc offering longer-lasting protection.

Chemical Properties: Sealed Zinc vs Unsealed Zinc

Sealed zinc exhibits enhanced resistance to corrosion and oxidation due to its protective barrier, which prevents exposure to moisture and air, thereby preserving its chemical stability. Unsealed zinc is more reactive, prone to surface degradation, and forms zinc oxide or hydroxide layers upon exposure to environmental elements. The chemical properties of sealed zinc make it preferable for applications requiring long-term durability and resistance to chemical breakdown.

Surface Protection: Benefits of Sealing Zinc

Sealed zinc surfaces provide enhanced corrosion resistance by creating a protective barrier that prevents moisture and airborne contaminants from penetrating the metal. This sealing process significantly extends the lifespan of zinc coatings by reducing oxidation and rust formation compared to unsealed zinc, which remains vulnerable to environmental damage. Maintaining surface integrity through sealing also minimizes maintenance costs and preserves the aesthetic appearance of zinc-treated materials.

Corrosion Resistance: Sealed and Unsealed Zinc Compared

Sealed zinc coatings provide superior corrosion resistance by creating a protective barrier that prevents moisture and contaminants from penetrating the metal surface, significantly reducing oxidative degradation. Unsealed zinc, while initially protective due to its sacrificial properties, is more susceptible to environmental factors like humidity and salt exposure, leading to faster corrosion over time. Applying a sealant enhances zinc's durability in harsh conditions, extending the lifespan of galvanized steel products in industrial and outdoor applications.

Durability in Different Environments

Sealed zinc coatings exhibit enhanced durability in harsh environments by providing a protective barrier against moisture, corrosion, and chemical exposure. Unsealed zinc is more susceptible to oxidation, leading to faster degradation and reduced lifespan when exposed to outdoor weather or industrial pollutants. The sealed option offers superior resistance to rust and wear, making it ideal for long-term applications in both marine and urban settings.

Aesthetic Differences: Sealed vs Unsealed Zinc Finishes

Sealed zinc finishes offer a smooth, uniform appearance with enhanced resistance to discoloration and corrosion, maintaining their aesthetic appeal over time. Unsealed zinc exhibits a natural patina that evolves, providing a rustic, textured look favored for artistic and architectural applications. The choice between sealed and unsealed zinc influences the longevity and visual character of surfaces exposed to varying environmental conditions.

Maintenance Requirements for Sealed and Unsealed Zinc

Sealed zinc requires minimal maintenance due to its protective coating that prevents oxidation and corrosion, making it ideal for long-term applications. Unsealed zinc, however, demands regular cleaning and occasional reapplication to combat surface degradation caused by exposure to moisture and air. Proper maintenance of unsealed zinc ensures longevity but involves more frequent inspections compared to sealed zinc.

Common Applications for Sealed and Unsealed Zinc

Sealed zinc coatings are commonly used in automotive parts, construction fasteners, and electrical components due to their enhanced corrosion resistance and durability in harsh environments. Unsealed zinc is often applied on household hardware, decorative items, and indoor applications where moderate protection against oxidation is sufficient. The choice between sealed and unsealed zinc coatings depends on exposure conditions, with sealed zinc preferred for outdoor or industrial use and unsealed zinc suited for low-moisture or indoor settings.

Environmental Impact of Sealants on Zinc

Sealed zinc surfaces minimize corrosion and extend the lifespan of zinc installations by preventing moisture and pollutants from accelerating metal degradation. However, the chemical sealants used can introduce volatile organic compounds (VOCs) and other harmful substances into the environment, potentially affecting air and water quality. Unsealed zinc corrodes more rapidly, releasing zinc oxide particles into ecosystems, but it avoids the ecological risks associated with synthetic sealant compounds.

Cost Analysis: Sealed Zinc versus Unsealed Zinc

Sealed zinc coatings typically incur higher initial costs due to additional sealing processes that enhance corrosion resistance and extend lifespan, reducing long-term maintenance expenses. Unsealed zinc, while less expensive upfront, may require more frequent repairs or replacements because it offers less protection against environmental factors. Evaluating total cost of ownership reveals sealed zinc as a cost-effective solution for applications demanding durability and reduced maintenance over time.

Sealed Zinc vs Unsealed Zinc Infographic

materialdif.com

materialdif.com