Chromate conversion coating provides superior corrosion resistance and enhances paint adhesion on zinc-plated surfaces compared to phosphate coating. It forms a thin, transparent layer that protects zinc pet components from oxidization and environmental damage. Phosphate coating, while effective for improving paint adhesion and providing moderate corrosion protection, typically results in a thicker, less uniform layer that may not perform as well in harsh conditions.

Table of Comparison

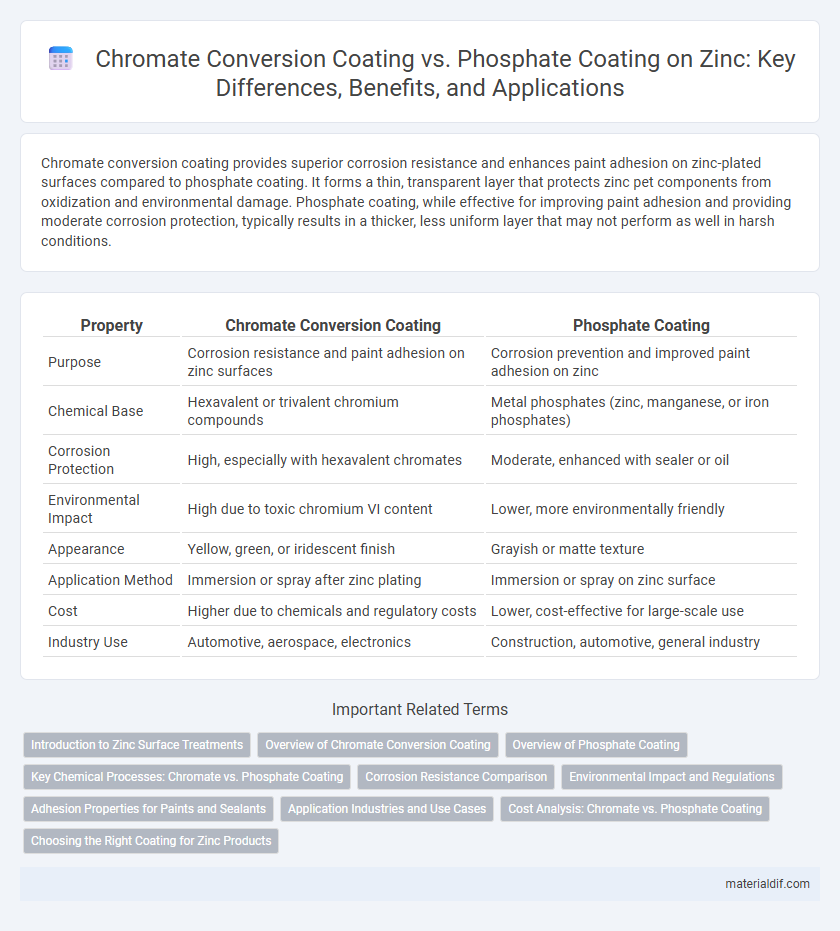

| Property | Chromate Conversion Coating | Phosphate Coating |

|---|---|---|

| Purpose | Corrosion resistance and paint adhesion on zinc surfaces | Corrosion prevention and improved paint adhesion on zinc |

| Chemical Base | Hexavalent or trivalent chromium compounds | Metal phosphates (zinc, manganese, or iron phosphates) |

| Corrosion Protection | High, especially with hexavalent chromates | Moderate, enhanced with sealer or oil |

| Environmental Impact | High due to toxic chromium VI content | Lower, more environmentally friendly |

| Appearance | Yellow, green, or iridescent finish | Grayish or matte texture |

| Application Method | Immersion or spray after zinc plating | Immersion or spray on zinc surface |

| Cost | Higher due to chemicals and regulatory costs | Lower, cost-effective for large-scale use |

| Industry Use | Automotive, aerospace, electronics | Construction, automotive, general industry |

Introduction to Zinc Surface Treatments

Chromate conversion coating and phosphate coating are two primary surface treatments used to enhance zinc's corrosion resistance and paint adhesion. Chromate conversion creates a thin, protective film of chromium compounds on zinc surfaces, offering superior corrosion protection, especially in harsh environments. Phosphate coating forms a crystalline phosphate layer that improves paint adhesion and corrosion resistance but generally provides less durability compared to chromate treatments.

Overview of Chromate Conversion Coating

Chromate conversion coating is a chemical treatment primarily applied to zinc surfaces to enhance corrosion resistance and provide a protective barrier against environmental factors. This coating forms a thin, passivating layer composed of chromium compounds, which helps prevent oxidation while improving adhesion for subsequent painting or sealing processes. Widely used in aerospace and automotive industries, chromate conversion coating offers superior corrosion protection compared to phosphate coatings, especially in harsh or marine environments.

Overview of Phosphate Coating

Phosphate coating creates a crystalline layer of insoluble metal phosphates on zinc surfaces, enhancing corrosion resistance and improving paint adhesion. This coating is typically formed through a chemical reaction involving phosphoric acid and metal ions, producing a robust and uniform protective film. Phosphate coatings are widely used in automotive and industrial applications due to their cost-effectiveness and excellent base for subsequent coatings or painting.

Key Chemical Processes: Chromate vs. Phosphate Coating

Chromate conversion coating involves the formation of a thin, protective oxide layer through the reduction of hexavalent chromium ions, creating a passivating barrier that enhances corrosion resistance on zinc surfaces. Phosphate coating, by contrast, relies on the chemical reaction between phosphate ions and zinc to produce an insoluble crystalline phosphate layer that improves adhesion and corrosion protection. Both processes modify the zinc substrate chemically, but chromate coatings provide superior self-healing properties due to the presence of chromium compounds, whereas phosphate coatings primarily offer mechanical adhesion benefits.

Corrosion Resistance Comparison

Chromate conversion coating on zinc provides superior corrosion resistance by forming a dense, adherent layer that inhibits oxidation and enhances durability in harsh environments. In contrast, phosphate coatings offer moderate corrosion protection by creating a crystalline phosphate layer that facilitates paint adhesion but is less effective against prolonged exposure to moisture and corrosive agents. Zinc with chromate conversion treatments exhibits enhanced long-term corrosion resistance, particularly in automotive and aerospace applications requiring high-performance protection.

Environmental Impact and Regulations

Chromate conversion coating on zinc offers effective corrosion resistance but poses significant environmental concerns due to hexavalent chromium, a known carcinogen regulated under strict EPA and REACH guidelines. Phosphate coating presents a more environmentally friendly alternative, producing fewer hazardous byproducts and complying with increasingly stringent international regulations on toxic waste disposal. The shift towards phosphate coatings aligns with global efforts to reduce hazardous chemical use and promote sustainable zinc surface treatments.

Adhesion Properties for Paints and Sealants

Chromate conversion coating on zinc surfaces significantly enhances adhesion properties for paints and sealants by creating a chemically reactive and corrosion-resistant layer that promotes strong bonding. In contrast, phosphate coating provides a crystalline surface that improves mechanical adhesion but generally offers lower chemical affinity compared to chromate treatments. The superior corrosion resistance and chemical bonding of chromate coatings result in longer-lasting paint adhesion and increased durability under harsh environmental conditions.

Application Industries and Use Cases

Chromate conversion coating is widely used in aerospace, electronics, and automotive industries due to its superior corrosion resistance and electrical conductivity, making it ideal for aluminum and zinc-plated steel surfaces. Phosphate coating finds extensive application in heavy machinery, agricultural equipment, and automotive manufacturing for its excellent paint adhesion and rust prevention on steel parts. Both coatings provide corrosion protection but differ in substrate compatibility and performance requirements, influencing their selection based on industry-specific use cases.

Cost Analysis: Chromate vs. Phosphate Coating

Chromate conversion coating typically incurs higher initial costs due to expensive chemical formulations and stricter environmental regulations, whereas phosphate coating offers a more cost-effective solution with lower material and disposal expenses. Maintenance costs for chromate coatings can be reduced by their superior corrosion resistance, potentially offsetting upfront investments over time. Phosphate coatings, favored in high-volume applications, benefit from faster processing times and lower labor costs, driving overall savings in large-scale production.

Choosing the Right Coating for Zinc Products

Chromate conversion coating offers superior corrosion resistance and enhanced adhesion for paints on zinc products, making it ideal for applications in harsh environments such as automotive and aerospace industries. Phosphate coating provides a more cost-effective solution with good wear resistance and is commonly used for improving paint adhesion on zinc in less demanding conditions like agricultural equipment. Selecting the right coating depends on balancing performance requirements, environmental exposure, and budget constraints for optimal protection and durability.

Chromate Conversion Coating vs Phosphate Coating Infographic

materialdif.com

materialdif.com