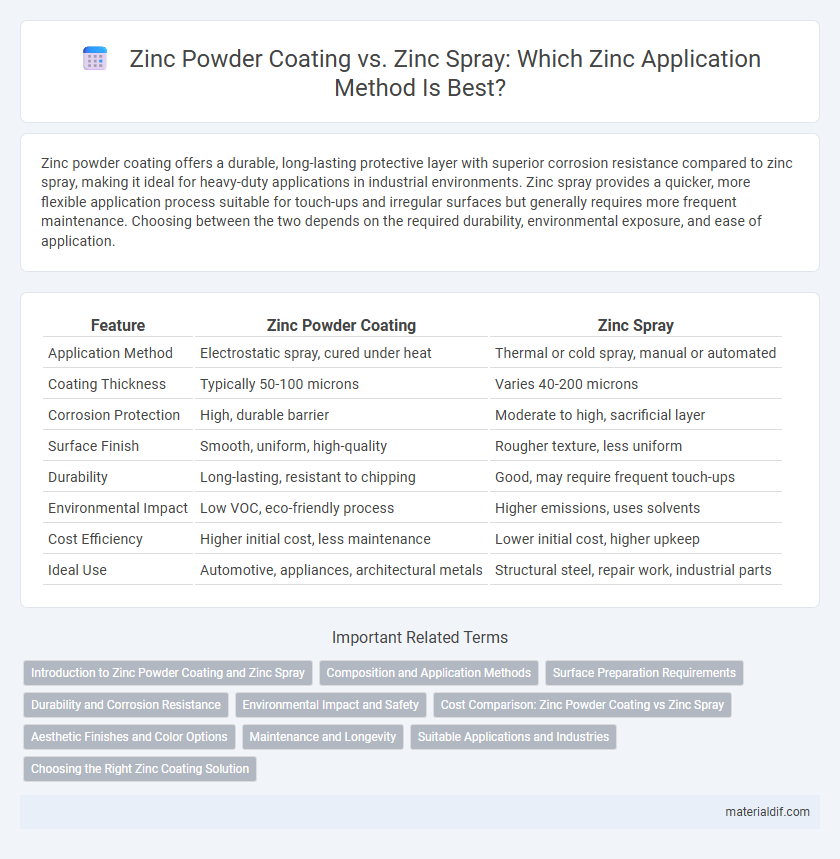

Zinc powder coating offers a durable, long-lasting protective layer with superior corrosion resistance compared to zinc spray, making it ideal for heavy-duty applications in industrial environments. Zinc spray provides a quicker, more flexible application process suitable for touch-ups and irregular surfaces but generally requires more frequent maintenance. Choosing between the two depends on the required durability, environmental exposure, and ease of application.

Table of Comparison

| Feature | Zinc Powder Coating | Zinc Spray |

|---|---|---|

| Application Method | Electrostatic spray, cured under heat | Thermal or cold spray, manual or automated |

| Coating Thickness | Typically 50-100 microns | Varies 40-200 microns |

| Corrosion Protection | High, durable barrier | Moderate to high, sacrificial layer |

| Surface Finish | Smooth, uniform, high-quality | Rougher texture, less uniform |

| Durability | Long-lasting, resistant to chipping | Good, may require frequent touch-ups |

| Environmental Impact | Low VOC, eco-friendly process | Higher emissions, uses solvents |

| Cost Efficiency | Higher initial cost, less maintenance | Lower initial cost, higher upkeep |

| Ideal Use | Automotive, appliances, architectural metals | Structural steel, repair work, industrial parts |

Introduction to Zinc Powder Coating and Zinc Spray

Zinc powder coating and zinc spray are two popular methods for applying zinc to surfaces for corrosion protection. Zinc powder coating involves applying a dry, powdery zinc-rich material electrostatically to metal and then curing it under heat to form a tough, protective layer. Zinc spray, or thermal spraying, uses heated zinc particles sprayed onto surfaces, creating a metallurgical bond that offers effective rust resistance and durability.

Composition and Application Methods

Zinc powder coating consists primarily of micronized zinc particles combined with binders and pigments, applied through electrostatic spraying and cured under heat to form a durable protective layer. Zinc spray involves molten zinc or zinc alloys sprayed onto surfaces using thermal spray guns, creating a thick, metallurgically bonded coating ideal for corrosion resistance. Both methods are widely used in industrial corrosion protection, with powder coating offering smoother finishes and spray providing robust, thicker coatings on complex structures.

Surface Preparation Requirements

Zinc powder coating requires thorough surface cleaning and degreasing to ensure proper adhesion and uniform coverage, often necessitating abrasive blasting to remove rust and contaminants effectively. Zinc spray, while still demanding a clean surface, can tolerate slightly less intensive preparation, such as wire brushing or solvent cleaning, due to its ability to better conform to irregular surfaces. Both methods benefit from dry, oil-free substrates to maximize coating durability and corrosion resistance.

Durability and Corrosion Resistance

Zinc powder coating offers superior durability and corrosion resistance by providing a thicker, more uniform protective layer that withstands harsh environmental conditions better than zinc spray. Zinc spray, while easier to apply for quick touch-ups, tends to have a thinner coating that is more susceptible to wear and faster corrosion over time. For long-term protection of metal surfaces, zinc powder coating is the preferred choice due to its enhanced adhesion and resistance to abrasion and moisture.

Environmental Impact and Safety

Zinc powder coating offers a lower environmental impact compared to zinc spray due to reduced volatile organic compounds (VOCs) emissions and minimized hazardous waste generation. Zinc spray processes often release metal particles and fumes that require strict respiratory protection and effective ventilation for worker safety. Choosing zinc powder coating enhances workplace safety and sustainability by limiting airborne contaminants and supporting eco-friendly practices.

Cost Comparison: Zinc Powder Coating vs Zinc Spray

Zinc powder coating generally incurs higher upfront costs due to equipment and application processes, but it offers superior durability and longer-lasting protection compared to zinc spray. Zinc spray is more cost-effective for smaller projects or touch-ups, providing a quicker and less expensive solution with lower material and labor expenses. Over time, the extended lifespan of zinc powder coatings can lead to reduced maintenance costs, making it economically advantageous for large-scale or high-exposure applications.

Aesthetic Finishes and Color Options

Zinc powder coating provides a durable, uniform finish with a wider range of color options, enhancing aesthetic appeal for industrial and decorative applications. Zinc spray, while offering a more textured and matte appearance, is typically limited to natural metallic hues, making it ideal for restoring zinc surfaces without altering their original color. Selecting between zinc powder coating and zinc spray depends on the desired visual effect and the need for specific color customization.

Maintenance and Longevity

Zinc powder coating offers superior durability and corrosion resistance compared to zinc spray, resulting in longer-lasting protection with minimal maintenance. Its dense, uniform layer reduces the need for frequent touch-ups or reapplications, making it ideal for high-exposure environments. Zinc spray, while easier to apply for quick repairs, typically requires more regular maintenance due to its thinner, less consistent coverage.

Suitable Applications and Industries

Zinc powder coating provides a durable, corrosion-resistant finish ideal for heavy-duty applications in marine, automotive, and construction industries where long-lasting protection against rust is crucial. Zinc spray offers a more flexible, cost-effective solution suitable for touch-ups, repairs, and irregular surfaces commonly found in manufacturing, maintenance, and infrastructure sectors. Both methods enhance steel longevity, with powder coating preferred for large-scale, high-exposure environments and spray coating favored for precision and maintenance tasks.

Choosing the Right Zinc Coating Solution

Zinc powder coating provides a durable and uniform protective layer ideal for heavy-duty applications, offering superior corrosion resistance and longer-lasting performance. Zinc spray, by comparison, allows for easy touch-ups and on-site application, making it suitable for maintenance and repair tasks with faster drying times. Selecting the right zinc coating depends on factors such as exposure to environmental elements, application complexity, and desired lifespan of the protection.

Zinc Powder Coating vs Zinc Spray Infographic

materialdif.com

materialdif.com