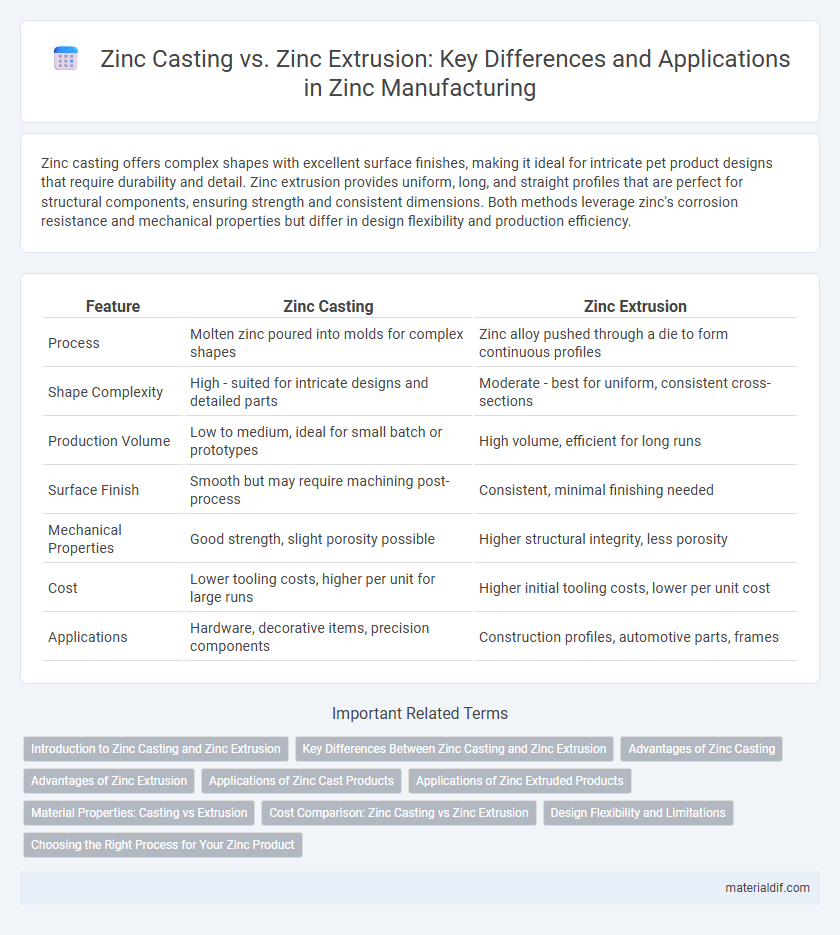

Zinc casting offers complex shapes with excellent surface finishes, making it ideal for intricate pet product designs that require durability and detail. Zinc extrusion provides uniform, long, and straight profiles that are perfect for structural components, ensuring strength and consistent dimensions. Both methods leverage zinc's corrosion resistance and mechanical properties but differ in design flexibility and production efficiency.

Table of Comparison

| Feature | Zinc Casting | Zinc Extrusion |

|---|---|---|

| Process | Molten zinc poured into molds for complex shapes | Zinc alloy pushed through a die to form continuous profiles |

| Shape Complexity | High - suited for intricate designs and detailed parts | Moderate - best for uniform, consistent cross-sections |

| Production Volume | Low to medium, ideal for small batch or prototypes | High volume, efficient for long runs |

| Surface Finish | Smooth but may require machining post-process | Consistent, minimal finishing needed |

| Mechanical Properties | Good strength, slight porosity possible | Higher structural integrity, less porosity |

| Cost | Lower tooling costs, higher per unit for large runs | Higher initial tooling costs, lower per unit cost |

| Applications | Hardware, decorative items, precision components | Construction profiles, automotive parts, frames |

Introduction to Zinc Casting and Zinc Extrusion

Zinc casting involves melting zinc alloys and injecting them into molds to create intricate shapes with fine details, making it ideal for complex components. Zinc extrusion forces heated zinc billets through a die to produce long, uniform profiles with excellent mechanical properties and surface finish. Both methods leverage zinc's low melting point and corrosion resistance but cater to distinct industrial applications based on design complexity and production volume.

Key Differences Between Zinc Casting and Zinc Extrusion

Zinc casting involves pouring molten zinc into molds to create complex shapes with high dimensional accuracy, making it ideal for intricate components. Zinc extrusion, on the other hand, forces zinc through a die to produce uniform cross-sectional profiles, offering enhanced mechanical strength and material efficiency. The key differences include casting's flexibility in design complexity versus extrusion's consistency and strength in linear shapes.

Advantages of Zinc Casting

Zinc casting offers superior design flexibility, allowing the creation of complex shapes and intricate details that extrusion cannot achieve. It provides excellent corrosion resistance and high tensile strength, making cast zinc components durable for various industrial applications. The cost-effectiveness of zinc casting for small to medium production runs ensures precise dimension control with minimal post-processing requirements.

Advantages of Zinc Extrusion

Zinc extrusion offers superior mechanical properties such as increased tensile strength and enhanced surface finish compared to zinc casting. The extrusion process allows for precise dimensional control and complex cross-sectional shapes, making it ideal for structural applications requiring durability and consistency. Furthermore, zinc extrusion minimizes material waste and improves production efficiency, resulting in cost-effective manufacturing.

Applications of Zinc Cast Products

Zinc cast products are extensively utilized in automotive components, electrical housings, and decorative hardware due to their complex shapes and high strength-to-weight ratio. These castings provide excellent corrosion resistance and dimensional accuracy, making them ideal for precision parts in consumer electronics and industrial machinery. Compared to zinc extrusion, casting allows for more intricate designs and cost-effective production of small to medium-sized components.

Applications of Zinc Extruded Products

Zinc extruded products are widely used in the automotive industry for structural components due to their high strength-to-weight ratio and excellent corrosion resistance. These products also find applications in architectural frameworks, offering durable and aesthetically versatile solutions for window frames and decorative trims. The electronics sector utilizes zinc extrusions for heat sinks and enclosures, benefiting from zinc's thermal conductivity and precision extrusion capabilities.

Material Properties: Casting vs Extrusion

Zinc casting allows for complex shapes and intricate details due to the fluidity of molten zinc, resulting in dense, fine-grained microstructures with excellent corrosion resistance and dimensional stability. Zinc extrusion produces elongated profiles with uniform cross-sections, offering superior mechanical strength and consistent grain flow that enhances tensile strength and fatigue resistance. While casting provides more design flexibility, extrusion delivers improved structural integrity and greater surface finish quality.

Cost Comparison: Zinc Casting vs Zinc Extrusion

Zinc casting typically involves higher initial tooling costs but offers cost efficiency for complex shapes and small to medium production runs due to lower machining requirements. Zinc extrusion presents lower tooling expenses and faster turnaround times, making it more cost-effective for large-volume, simpler profiles with minimal secondary processing. Selecting between zinc casting and extrusion depends on balancing production scale, design complexity, and overall cost constraints.

Design Flexibility and Limitations

Zinc casting offers superior design flexibility, enabling complex shapes, intricate details, and undercuts with minimal tooling changes, making it ideal for customized and decorative components. Zinc extrusion, while providing excellent strength and uniformity, is limited to producing linear profiles with consistent cross-sections, restricting design complexity. Both processes suit different applications where zinc casting excels in detailed designs and zinc extrusion favors structural simplicity.

Choosing the Right Process for Your Zinc Product

Zinc casting offers intricate design capabilities and excellent corrosion resistance, making it ideal for complex parts and detailed components. In contrast, zinc extrusion provides superior strength and consistent cross-sectional profiles, suitable for structural applications and long, uniform shapes. Selecting the right process depends on product requirements such as design complexity, mechanical properties, and production volume.

Zinc Casting vs Zinc Extrusion Infographic

materialdif.com

materialdif.com