Thermal spray zinc creates a robust, thick coating that offers excellent corrosion resistance by melting zinc particles onto the surface, making it ideal for heavy-duty industrial applications. Cold spray zinc, on the other hand, uses high-velocity zinc particles deposited without melting, resulting in a denser and less oxidized layer that preserves zinc's metallurgical properties better. Choosing between thermal spray and cold spray zinc depends on the specific environmental exposure and performance requirements for pet-related equipment protection.

Table of Comparison

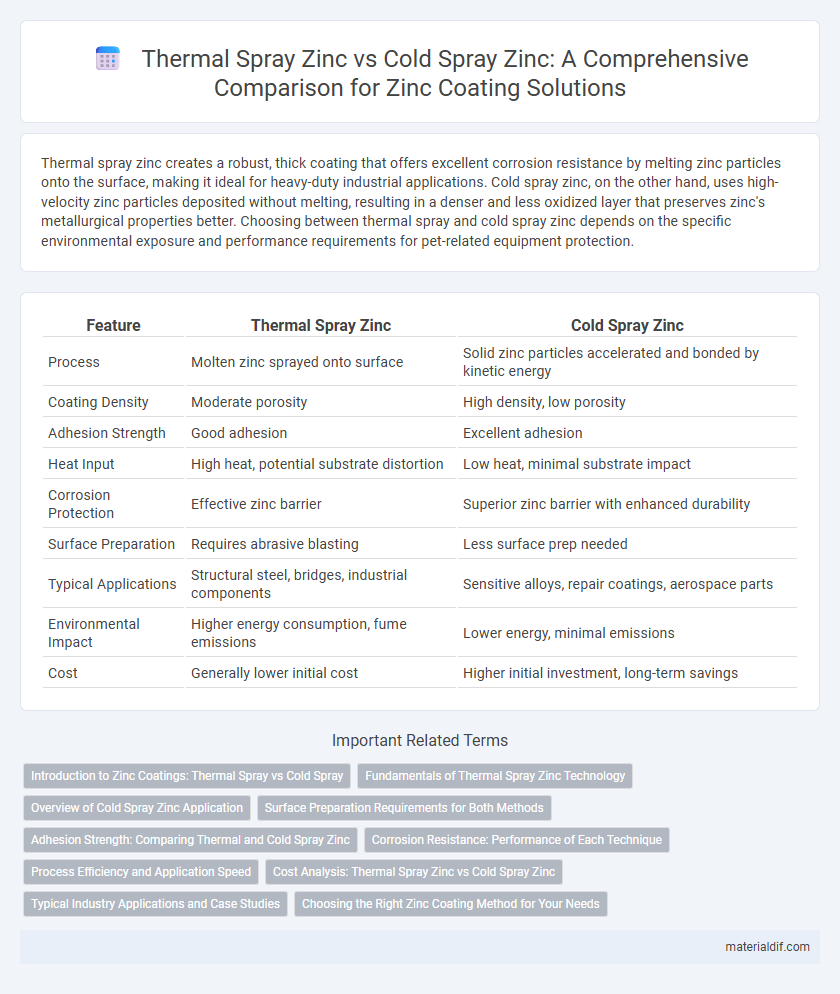

| Feature | Thermal Spray Zinc | Cold Spray Zinc |

|---|---|---|

| Process | Molten zinc sprayed onto surface | Solid zinc particles accelerated and bonded by kinetic energy |

| Coating Density | Moderate porosity | High density, low porosity |

| Adhesion Strength | Good adhesion | Excellent adhesion |

| Heat Input | High heat, potential substrate distortion | Low heat, minimal substrate impact |

| Corrosion Protection | Effective zinc barrier | Superior zinc barrier with enhanced durability |

| Surface Preparation | Requires abrasive blasting | Less surface prep needed |

| Typical Applications | Structural steel, bridges, industrial components | Sensitive alloys, repair coatings, aerospace parts |

| Environmental Impact | Higher energy consumption, fume emissions | Lower energy, minimal emissions |

| Cost | Generally lower initial cost | Higher initial investment, long-term savings |

Introduction to Zinc Coatings: Thermal Spray vs Cold Spray

Thermal spray zinc coatings utilize molten zinc particles propelled at high velocity to create a dense, corrosion-resistant layer commonly used in industrial applications. Cold spray zinc coatings involve accelerating solid zinc particles at supersonic speeds to form coatings without melting, preserving the zinc's metallurgical properties and enhancing adhesion. Both methods provide effective corrosion protection but differ significantly in temperature, particle state, and bonding mechanisms, influencing coating performance and application suitability.

Fundamentals of Thermal Spray Zinc Technology

Thermal spray zinc technology involves the application of molten or semi-molten zinc particles onto a substrate, creating a dense, corrosion-resistant coating that enhances metal durability in harsh environments. This process relies on high-temperature flame or plasma to melt zinc wire or powder, which is then projected at high velocity to form a strong metallurgical bond with the surface. Compared to cold spray zinc, thermal spray produces thicker coatings with excellent adhesion and sacrificial protection, making it ideal for industrial corrosion control.

Overview of Cold Spray Zinc Application

Cold spray zinc application involves propelling fine zinc particles at supersonic speeds onto a substrate, creating a dense, corrosion-resistant coating without melting the metal. This process preserves the mechanical properties of both the zinc and the substrate, resulting in enhanced adhesion and superior protection against environmental degradation. Unlike thermal spray zinc, cold spray avoids oxidation and thermal distortion, making it ideal for repairing sensitive components and providing long-lasting corrosion resistance.

Surface Preparation Requirements for Both Methods

Thermal spray zinc requires thorough surface preparation including grit blasting to create a rough profile that ensures strong adhesion and coating durability. Cold spray zinc demands less aggressive surface preparation, often limited to cleaning and light abrasion to maintain substrate integrity while promoting mechanical bonding. Both methods emphasize contamination-free surfaces but differ in the extent of preparation due to their distinct application temperatures and particle velocities.

Adhesion Strength: Comparing Thermal and Cold Spray Zinc

Thermal spray zinc coatings exhibit moderate adhesion strength due to their high-temperature application, which can cause oxidation and surface roughness variations affecting bond quality. Cold spray zinc coatings achieve superior adhesion strength by accelerating zinc particles at high velocities without melting, resulting in dense, oxide-free layers with excellent mechanical interlocking. Studies demonstrate that cold spray zinc outperforms thermal spray zinc in corrosion resistance and durability, attributing enhanced adhesion strength to minimal thermal distortion and stronger substrate bonding.

Corrosion Resistance: Performance of Each Technique

Thermal spray zinc coatings provide a thick, dense layer that offers excellent corrosion resistance by forming a strong barrier against environmental elements. Cold spray zinc deposits zinc particles at high velocity, producing a more uniform and less porous coating with enhanced adhesion, resulting in superior resistance to corrosion and longer service life. Both techniques improve corrosion resistance, but cold spray zinc typically outperforms thermal spray zinc in environments requiring higher durability and mechanical integrity.

Process Efficiency and Application Speed

Thermal spray zinc offers faster deposition rates due to its molten particle application, improving application speed on large surface areas compared to cold spray zinc, which uses high-velocity solid particles for coating. Cold spray zinc provides superior process efficiency in terms of minimal heat input and lower oxidation, resulting in enhanced coating adhesion and reduced thermal distortion. Selecting between thermal spray and cold spray zinc depends on the balance between rapid coverage needs and achieving higher-quality, low-temperature coatings.

Cost Analysis: Thermal Spray Zinc vs Cold Spray Zinc

Thermal Spray Zinc generally incurs higher operational costs due to the fuel consumption and equipment maintenance involved in the high-temperature process, while Cold Spray Zinc features lower energy demands and reduced wear on machinery, leading to cost savings over time. Initial capital expenditure for Cold Spray Zinc equipment is typically higher, but its efficiency in material utilization and minimal surface preparation can offset these costs in large-scale applications. Overall, cost efficiency between Thermal Spray and Cold Spray Zinc depends on the project's scale, application complexity, and long-term maintenance considerations.

Typical Industry Applications and Case Studies

Thermal spray zinc is widely used in automotive, construction, and marine industries for corrosion protection on steel structures and pipelines, leveraging its effective coating thickness and strong adhesion. Cold spray zinc, favored in aerospace and electronics, provides precise, low-heat application suitable for sensitive materials and repairs, maintaining substrate integrity. Case studies reveal thermal spray zinc's success in large-scale infrastructure projects, while cold spray zinc excels in aerospace component restoration and electronic device shielding.

Choosing the Right Zinc Coating Method for Your Needs

Thermal spray zinc provides a thicker, more durable coating ideal for heavy-duty corrosion protection on large structures, while cold spray zinc offers a denser, low-heat application suitable for delicate substrates and precise repairs. Selecting the right zinc coating method depends on factors such as substrate sensitivity, required coating thickness, and environmental exposure. Understanding the specific performance characteristics of thermal spray versus cold spray zinc ensures optimal protection and longevity tailored to your project's demands.

Thermal Spray Zinc vs Cold Spray Zinc Infographic

materialdif.com

materialdif.com