Shrinkage porosity in zinc castings occurs due to volume reduction as the metal solidifies, resulting in voids or cavities within the casting structure. Gas porosity arises from trapped gas during the molten metal's cooling process, creating spherical or irregular bubbles. Differentiating between these defects is crucial for optimizing cast quality and ensuring mechanical integrity in zinc pet applications.

Table of Comparison

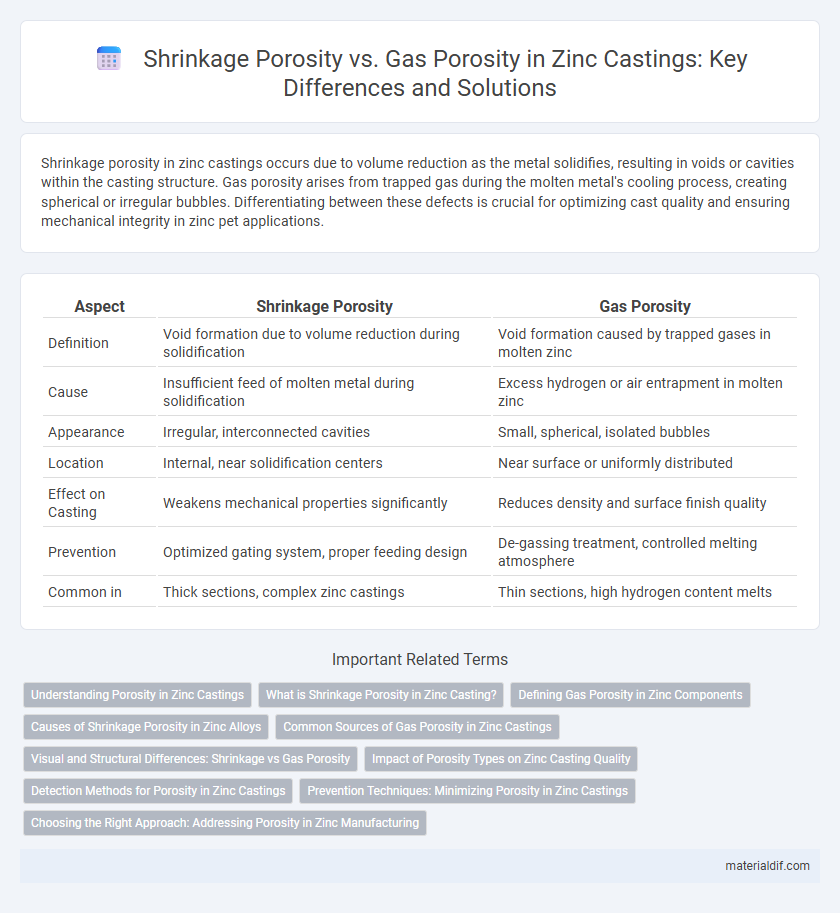

| Aspect | Shrinkage Porosity | Gas Porosity |

|---|---|---|

| Definition | Void formation due to volume reduction during solidification | Void formation caused by trapped gases in molten zinc |

| Cause | Insufficient feed of molten metal during solidification | Excess hydrogen or air entrapment in molten zinc |

| Appearance | Irregular, interconnected cavities | Small, spherical, isolated bubbles |

| Location | Internal, near solidification centers | Near surface or uniformly distributed |

| Effect on Casting | Weakens mechanical properties significantly | Reduces density and surface finish quality |

| Prevention | Optimized gating system, proper feeding design | De-gassing treatment, controlled melting atmosphere |

| Common in | Thick sections, complex zinc castings | Thin sections, high hydrogen content melts |

Understanding Porosity in Zinc Castings

Shrinkage porosity in zinc castings results from the volume reduction during solidification, causing voids that typically appear as irregular cavities. Gas porosity arises from dissolved gases, such as hydrogen, coming out of the melt and forming spherical pores within the casting structure. Understanding the differences between shrinkage and gas porosity is crucial for optimizing casting quality and minimizing defects in zinc alloys.

What is Shrinkage Porosity in Zinc Casting?

Shrinkage porosity in zinc casting refers to the formation of voids or cavities caused by the metal volume reduction during solidification. This defect occurs when molten zinc fails to adequately feed the solidifying metal, leading to localized density reductions and compromised mechanical strength. Identifying and controlling cooling rates and mold design can minimize shrinkage porosity and improve casting integrity.

Defining Gas Porosity in Zinc Components

Gas porosity in zinc castings refers to microscopic voids formed due to trapped gases during solidification, significantly impacting the mechanical properties of zinc components. Unlike shrinkage porosity, which results from volume contraction as zinc solidifies, gas porosity arises from inadequate venting or dissolved gases such as hydrogen releasing within the molten metal. Controlling gas porosity involves optimizing melt cleanliness, degassing procedures, and casting parameters to ensure high-density and defect-free zinc castings.

Causes of Shrinkage Porosity in Zinc Alloys

Shrinkage porosity in zinc castings primarily results from inadequate feeding during solidification, where volumetric contraction causes voids due to insufficient molten metal supply. The high thermal conductivity and rapid solidification rate of zinc alloys intensify this effect, leading to localized cavities near thick sections or junctions. Controlling mold temperature and optimizing riser placement are critical to reducing shrinkage porosity defects in zinc alloy castings.

Common Sources of Gas Porosity in Zinc Castings

Common sources of gas porosity in zinc castings include hydrogen absorption during melting, moisture on the surface of the mold or in the metal charge, and volatile contaminants from lubricants or coatings. Hydrogen is particularly problematic due to its high solubility in molten zinc and its low solubility in solidified metal, leading to gas entrapment and pore formation. Controlling gas porosity requires careful handling of raw materials, maintaining dry conditions, and using degassing techniques during zinc melting and casting.

Visual and Structural Differences: Shrinkage vs Gas Porosity

Shrinkage porosity in zinc castings appears as irregular, interconnected voids caused by volume contraction during solidification, often located near the casting's thick sections and showing a darker, dendritic microstructure around the pores. Gas porosity presents as small, rounded, and evenly distributed spherical pores resulting from trapped gases, exhibiting a more uniform surface texture with distinct, smooth pore boundaries. These visual and structural differences in porosity critically impact the mechanical properties and surface finish of zinc castings.

Impact of Porosity Types on Zinc Casting Quality

Shrinkage porosity in zinc castings primarily occurs due to inadequate feed metal during solidification, leading to voids that compromise mechanical strength and surface finish. Gas porosity arises from trapped gases like hydrogen, causing internal cavities that reduce ductility and create stress concentration points. Differentiating these porosity types is essential for optimizing casting parameters and enhancing the overall quality and reliability of zinc cast components.

Detection Methods for Porosity in Zinc Castings

Shrinkage porosity in zinc castings manifests as voids formed from insufficient metal feeding during solidification, while gas porosity arises from trapped gases such as hydrogen. Detection methods for these porosities include X-ray radiography, which effectively identifies internal voids by differential density, and ultrasonic testing that detects discontinuities through acoustic impedance variations. Advanced techniques like computed tomography provide 3D visualization, enhancing the accuracy of porosity assessment in zinc cast components.

Prevention Techniques: Minimizing Porosity in Zinc Castings

Shrinkage porosity in zinc castings occurs due to inadequate feeding during solidification, leading to voids as the metal contracts, whereas gas porosity forms from entrapped gases unable to escape. Minimizing porosity involves optimizing gating and riser design to ensure proper metal flow and feeding, and controlling mold temperature and metal cleanliness to reduce gas entrapment. Employing vacuum casting or using degassed molten zinc further prevents gas porosity, enhancing the overall casting integrity and mechanical properties.

Choosing the Right Approach: Addressing Porosity in Zinc Manufacturing

Shrinkage porosity in zinc castings results from volumetric contraction during solidification, manifesting as voids primarily in thicker sections, whereas gas porosity arises from entrapped gases like hydrogen, creating spherical pores throughout the casting. Selecting the appropriate approach involves controlling solidification rates and mold design to minimize shrinkage porosity, while degassing techniques and molten metal cleanliness are critical to reducing gas porosity. Optimizing these factors enhances mechanical properties and surface finish in zinc manufacturing.

Shrinkage Porosity vs Gas Porosity (in Zinc Castings) Infographic

materialdif.com

materialdif.com