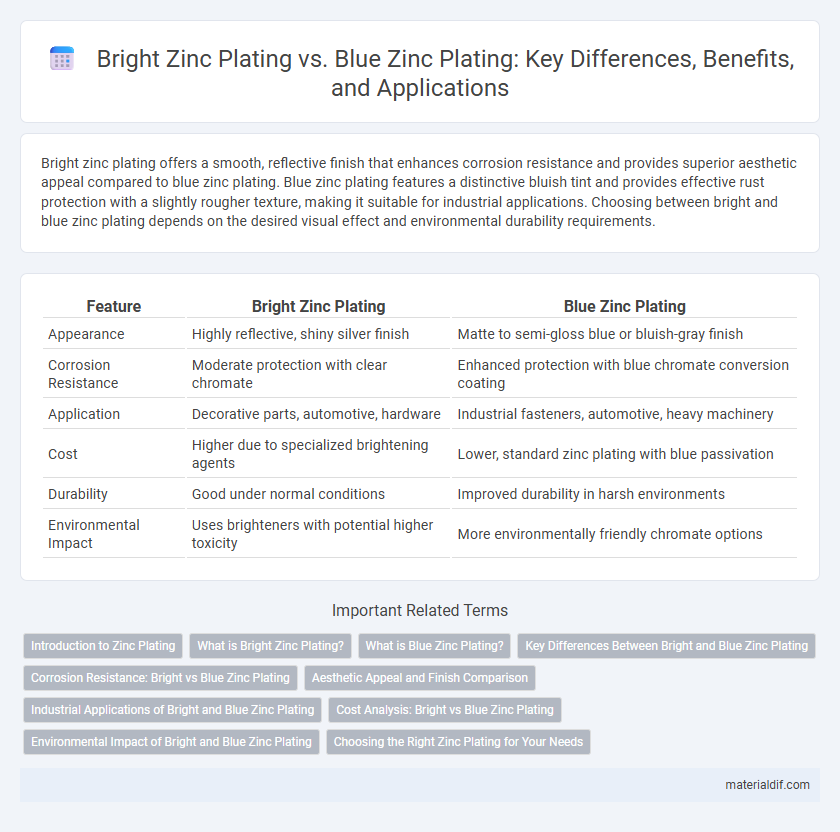

Bright zinc plating offers a smooth, reflective finish that enhances corrosion resistance and provides superior aesthetic appeal compared to blue zinc plating. Blue zinc plating features a distinctive bluish tint and provides effective rust protection with a slightly rougher texture, making it suitable for industrial applications. Choosing between bright and blue zinc plating depends on the desired visual effect and environmental durability requirements.

Table of Comparison

| Feature | Bright Zinc Plating | Blue Zinc Plating |

|---|---|---|

| Appearance | Highly reflective, shiny silver finish | Matte to semi-gloss blue or bluish-gray finish |

| Corrosion Resistance | Moderate protection with clear chromate | Enhanced protection with blue chromate conversion coating |

| Application | Decorative parts, automotive, hardware | Industrial fasteners, automotive, heavy machinery |

| Cost | Higher due to specialized brightening agents | Lower, standard zinc plating with blue passivation |

| Durability | Good under normal conditions | Improved durability in harsh environments |

| Environmental Impact | Uses brighteners with potential higher toxicity | More environmentally friendly chromate options |

Introduction to Zinc Plating

Zinc plating is a corrosion-resistant coating process that applies a thin layer of zinc to metal surfaces, enhancing durability and preventing rust. Bright zinc plating produces a shiny, reflective finish ideal for decorative or visible components, while blue zinc plating offers a more matte, bluish tint suited for industrial applications requiring additional corrosion protection. Both plating types provide sacrificial protection by oxidizing before the underlying metal, extending the lifespan of steel and iron parts.

What is Bright Zinc Plating?

Bright zinc plating is a corrosion-resistant coating process that deposits a smooth, reflective zinc layer onto metal surfaces, often using a specialized electrolyte containing brighteners to enhance luster. This plating method provides superior adhesion and an aesthetically appealing shiny finish, commonly applied in automotive, hardware, and electronics industries. Unlike blue zinc plating, bright zinc plating prioritizes high brightness and smoothness while maintaining effective protection against rust and wear.

What is Blue Zinc Plating?

Blue zinc plating is a type of zinc coating applied to metal surfaces to provide corrosion resistance and a distinct blue iridescent finish caused by a chromate conversion layer. This plating enhances durability by inhibiting rust formation, making it ideal for automotive and industrial parts exposed to harsh environments. The blue tint results from a specific chromate treatment that differentiates it from standard bright zinc plating, which typically has a shiny silver appearance without the protective chromate layer.

Key Differences Between Bright and Blue Zinc Plating

Bright zinc plating offers a highly reflective, smooth finish ideal for decorative purposes and corrosion resistance, while blue zinc plating provides a matte to semi-bright appearance with enhanced rust protection due to its chromate conversion coating. Bright zinc plating typically involves a cyanide-based process that yields superior luster, whereas blue zinc plating uses a non-cyanide process that emphasizes durability in harsher environments. Both plating methods improve steel corrosion resistance but differ significantly in aesthetics, chemical composition, and application suitability.

Corrosion Resistance: Bright vs Blue Zinc Plating

Bright zinc plating offers moderate corrosion resistance with a shiny, reflective finish that is ideal for decorative applications but requires additional clear coating for enhanced protection. Blue zinc plating provides superior corrosion resistance due to its chromate conversion coating, which enhances durability and longevity in harsh environments. Both platings extend the life of steel components, but blue zinc plating is preferred for industrial use where enhanced protection against rust and corrosion is critical.

Aesthetic Appeal and Finish Comparison

Bright zinc plating offers a highly reflective, mirror-like finish that enhances the aesthetic appeal of metal parts with a smooth and shiny surface. In contrast, blue zinc plating features a matte to semi-gloss finish with a distinctive bluish tint, providing a more subdued and modern appearance. The choice between bright and blue zinc plating depends on desired visual impact and finish durability requirements for the application.

Industrial Applications of Bright and Blue Zinc Plating

Bright zinc plating offers superior corrosion resistance and aesthetic appeal, making it ideal for automotive parts and consumer electronics where both durability and appearance are critical. Blue zinc plating is commonly used in industrial machinery and construction due to its enhanced adhesion and thicker coating, providing robust protection in harsh environmental conditions. Both finishes facilitate improved longevity and wear resistance, catering to specific industrial needs based on exposure and functional requirements.

Cost Analysis: Bright vs Blue Zinc Plating

Bright zinc plating generally incurs higher costs due to the added chemicals and process control required to achieve its reflective finish, making it suitable for decorative applications. Blue zinc plating is more cost-effective, offering enhanced corrosion resistance with a duller finish, preferred in industrial or functional settings. Budget-conscious projects often choose blue zinc plating to balance performance and affordability.

Environmental Impact of Bright and Blue Zinc Plating

Bright zinc plating typically involves the use of hexavalent chromium and other toxic chemicals, resulting in higher environmental hazards due to hazardous waste generation and potential water contamination. Blue zinc plating, often produced via trivalent chromium passivation or other less toxic alternatives, offers a reduced environmental footprint by minimizing the release of carcinogenic substances and improving waste management. Choosing blue zinc plating can significantly decrease ecological risks and aligns better with stricter environmental regulations in metal finishing industries.

Choosing the Right Zinc Plating for Your Needs

Bright zinc plating offers a highly reflective, smooth finish that provides excellent corrosion resistance, making it ideal for decorative and automotive applications. Blue zinc plating, with its slightly duller, bluish tint, focuses on enhanced durability and is commonly used in industrial and heavy-duty environments. Choosing the right zinc plating depends on the balance between aesthetic appeal and functional protection required for the specific application.

Bright Zinc Plating vs Blue Zinc Plating Infographic

materialdif.com

materialdif.com