Sheet zinc offers superior corrosion resistance and a natural self-healing ability, making it ideal for long-lasting applications exposed to harsh environments. Galvanized steel, coated with zinc, provides a more cost-effective solution with strong structural strength and moderate corrosion protection. Choosing between sheet zinc and galvanized steel depends on balancing durability needs with budget considerations for construction or manufacturing projects.

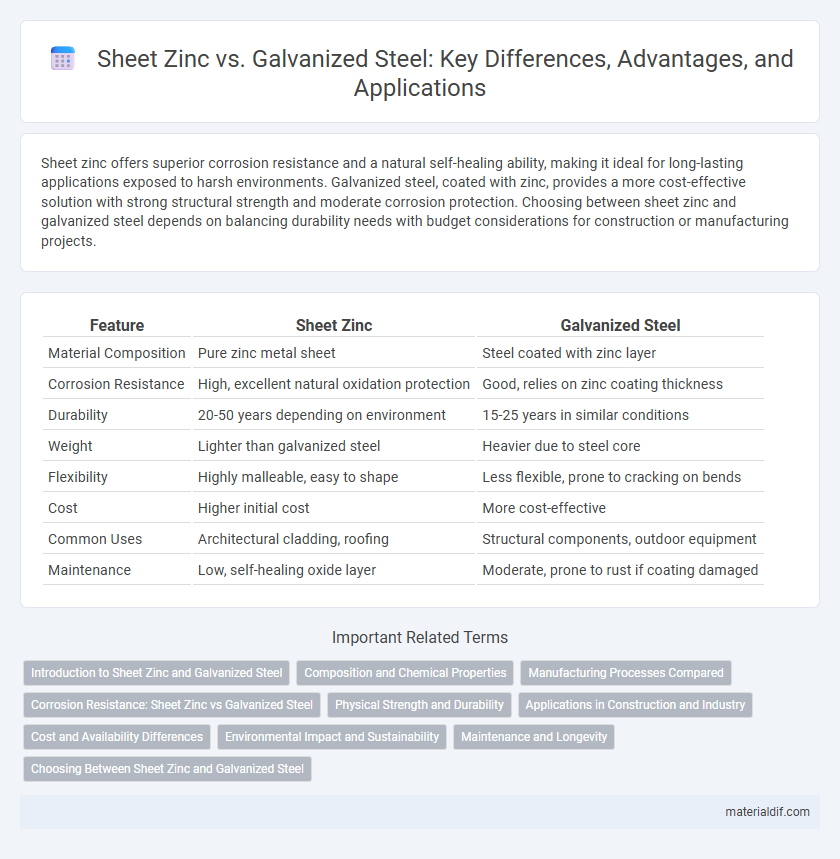

Table of Comparison

| Feature | Sheet Zinc | Galvanized Steel |

|---|---|---|

| Material Composition | Pure zinc metal sheet | Steel coated with zinc layer |

| Corrosion Resistance | High, excellent natural oxidation protection | Good, relies on zinc coating thickness |

| Durability | 20-50 years depending on environment | 15-25 years in similar conditions |

| Weight | Lighter than galvanized steel | Heavier due to steel core |

| Flexibility | Highly malleable, easy to shape | Less flexible, prone to cracking on bends |

| Cost | Higher initial cost | More cost-effective |

| Common Uses | Architectural cladding, roofing | Structural components, outdoor equipment |

| Maintenance | Low, self-healing oxide layer | Moderate, prone to rust if coating damaged |

Introduction to Sheet Zinc and Galvanized Steel

Sheet zinc is a corrosion-resistant metal primarily used in roofing, cladding, and architectural applications due to its natural patina that protects it from environmental elements. Galvanized steel consists of steel coated with a layer of zinc to enhance its rust resistance, commonly employed in construction, automotive, and industrial sectors. Both materials offer durability and protection, but sheet zinc provides inherent corrosion resistance, while galvanized steel relies on the zinc coating for protection.

Composition and Chemical Properties

Sheet zinc consists primarily of pure zinc with a composition of about 99.9% zinc, allowing it to resist corrosion through the formation of a protective oxide layer. Galvanized steel features a steel substrate coated with a zinc layer, combining steel's strength with zinc's anti-corrosive properties due to the sacrificial nature of zinc. Chemically, sheet zinc exhibits higher purity and uniformity, while galvanized steel benefits from the zinc coating's ability to prevent rusting of the underlying steel through galvanic protection.

Manufacturing Processes Compared

Sheet zinc is produced through a continuous casting and rolling process where pure zinc is melted, cast into slabs, and rolled into thin sheets ensuring corrosion resistance and malleability. Galvanized steel undergoes a hot-dip galvanizing process involving immersing steel sheets in molten zinc, creating a metallurgical bond that enhances durability and rust protection. The manufacturing of sheet zinc emphasizes purity and uniform thickness, while galvanized steel manufacturing prioritizes the steel substrate's strength combined with zinc's protective coating.

Corrosion Resistance: Sheet Zinc vs Galvanized Steel

Sheet zinc exhibits superior corrosion resistance due to its natural patina that forms a protective barrier, effectively preventing rust and degradation over time. Galvanized steel relies on a zinc coating that can deteriorate with mechanical damage or prolonged exposure, leading to potential corrosion once the protective layer is compromised. In environments with high moisture or acidic conditions, sheet zinc outperforms galvanized steel by maintaining integrity and extending the lifespan of structures.

Physical Strength and Durability

Sheet zinc exhibits moderate tensile strength ranging from 140 to 200 MPa, providing sufficient flexibility and corrosion resistance for roofing and cladding applications. Galvanized steel boasts higher tensile strength, typically between 370 and 500 MPa, due to its steel core, offering superior load-bearing capacity and impact resistance. In terms of durability, galvanized steel's zinc coating protects against rust, but the base steel remains vulnerable if the coating is damaged, while sheet zinc is inherently corrosion-resistant, maintaining its integrity over extended periods without underlying material degradation.

Applications in Construction and Industry

Sheet zinc offers superior corrosion resistance and aesthetic appeal, making it ideal for roofing, cladding, and decorative architectural elements in construction. Galvanized steel provides enhanced structural strength and is commonly used for framing, ductwork, and infrastructure components requiring durability under heavy loads. Both materials serve critical roles in industry, with sheet zinc favored for weatherproofing and galvanization enhancing steel's longevity in harsh environments.

Cost and Availability Differences

Sheet zinc typically has a higher upfront cost compared to galvanized steel due to its more specialized production process and raw material pricing. Galvanized steel is widely available and cost-effective, benefiting from mass production and common use in various construction applications. Availability of galvanized steel often leads to faster project timelines, whereas sheet zinc may require longer lead times depending on supplier inventory.

Environmental Impact and Sustainability

Sheet zinc offers superior environmental benefits compared to galvanized steel due to its recyclability and lower energy consumption during production. Zinc's natural self-healing properties reduce corrosion, extending the lifespan of structures and minimizing the need for replacements. Galvanized steel, coated with zinc layers, often requires more frequent maintenance and has a higher carbon footprint from steel production and hot-dip galvanizing processes.

Maintenance and Longevity

Sheet zinc exhibits superior corrosion resistance, requiring minimal maintenance due to its self-healing patina that protects against rust and environmental damage. Galvanized steel relies on a zinc coating that can degrade over time, necessitating periodic inspections and re-coating to prevent corrosion and extend its lifespan. The longevity of sheet zinc often surpasses galvanized steel, making it a cost-effective choice for long-term applications in both residential and industrial settings.

Choosing Between Sheet Zinc and Galvanized Steel

Choosing between sheet zinc and galvanized steel depends on the application's corrosion resistance and aesthetic requirements. Sheet zinc offers superior resistance to atmospheric corrosion and develops a protective patina over time, making it ideal for roofing and cladding in coastal or industrial environments. Galvanized steel provides cost-effective durability with a zinc coating that prevents rust, suitable for structural components and outdoor uses with moderate exposure to elements.

Sheet Zinc vs Galvanized Steel Infographic

materialdif.com

materialdif.com