Zinc sheets are thinner and more flexible, making them ideal for roofing, cladding, and decorative applications where easy shaping is required. Zinc plates are thicker and more rigid, suitable for industrial uses such as corrosion protection, structural components, and heavy-duty fabrication. Choosing between zinc sheet and plate depends on project needs for durability, flexibility, and installation ease.

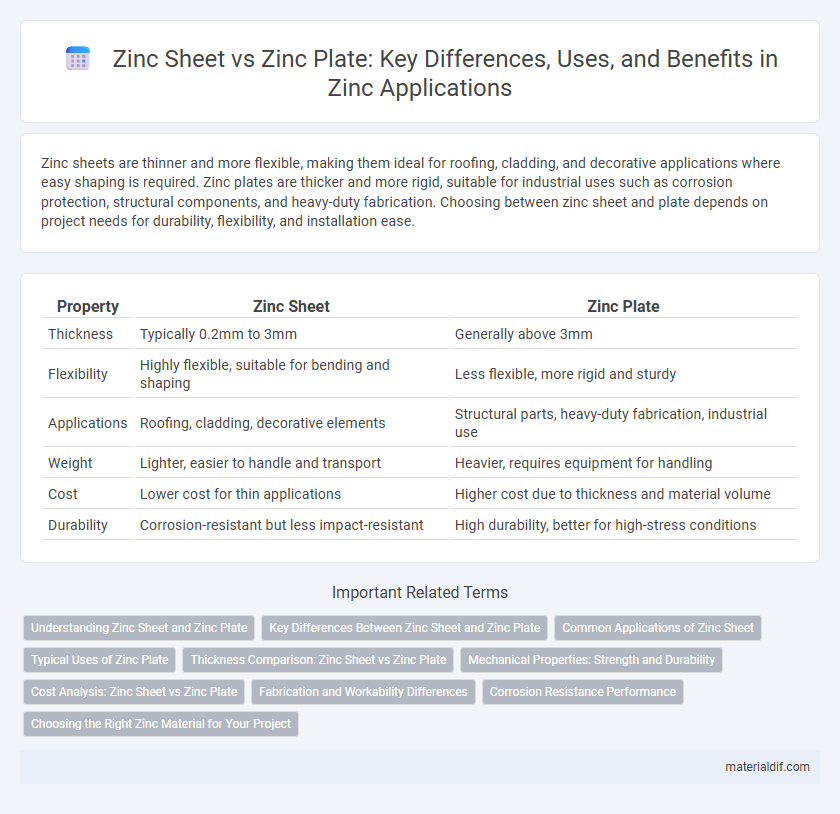

Table of Comparison

| Property | Zinc Sheet | Zinc Plate |

|---|---|---|

| Thickness | Typically 0.2mm to 3mm | Generally above 3mm |

| Flexibility | Highly flexible, suitable for bending and shaping | Less flexible, more rigid and sturdy |

| Applications | Roofing, cladding, decorative elements | Structural parts, heavy-duty fabrication, industrial use |

| Weight | Lighter, easier to handle and transport | Heavier, requires equipment for handling |

| Cost | Lower cost for thin applications | Higher cost due to thickness and material volume |

| Durability | Corrosion-resistant but less impact-resistant | High durability, better for high-stress conditions |

Understanding Zinc Sheet and Zinc Plate

Zinc sheets and zinc plates differ primarily in thickness and application; zinc sheets are thinner, ranging typically from 0.2mm to 3mm, making them ideal for roofing, cladding, and decorative uses. Zinc plates are thicker, usually above 3mm, providing greater strength and durability for industrial applications such as corrosion-resistant components and construction elements. Understanding these distinctions helps in selecting the appropriate zinc material for specific structural and protective requirements.

Key Differences Between Zinc Sheet and Zinc Plate

Zinc sheets are thin, flexible metal products typically measuring less than 3mm in thickness, making them suitable for roofing, cladding, and decorative applications due to their ease of fabrication. Zinc plates are thicker, often exceeding 3mm, providing greater structural strength and durability for industrial uses such as corrosion-resistant coatings and heavy-duty structural components. The key differences lie in thickness, flexibility, and intended application, with zinc sheets favored for lightweight, formable tasks and zinc plates required for robust, load-bearing purposes.

Common Applications of Zinc Sheet

Zinc sheets are commonly used in roofing, cladding, and gutter systems due to their flexibility, corrosion resistance, and ease of fabrication. These sheets are ideal for architectural applications where formability and aesthetic appeal are important. Zinc plates, by contrast, are thicker and primarily used in heavy-duty industrial applications such as construction of machinery or structural components.

Typical Uses of Zinc Plate

Zinc plate is commonly used in industrial applications such as corrosion-resistant coatings, electroplating, and manufacturing of batteries due to its purity and controlled thickness. It is favored for precision engineering components, including electrical connectors and hardware, where enhanced durability and conductivity are required. Unlike zinc sheets, zinc plates provide superior structural integrity for heavy-duty applications in construction and automotive industries.

Thickness Comparison: Zinc Sheet vs Zinc Plate

Zinc sheets typically range from 0.2 mm to 3 mm in thickness, making them thinner and more flexible for applications like roofing and cladding, whereas zinc plates generally measure above 3 mm, offering greater strength and rigidity suited for structural or industrial uses. The thickness difference influences the material's mechanical properties, with zinc plates providing higher durability and resistance to deformation compared to the thinner zinc sheets. Selecting between zinc sheet and zinc plate depends largely on project requirements, balancing thickness-related factors such as weight, malleability, and load-bearing capacity.

Mechanical Properties: Strength and Durability

Zinc sheets exhibit higher tensile strength and flexibility, making them suitable for applications requiring frequent bending and forming. Zinc plates offer superior thickness and hardness, providing enhanced durability and resistance to wear in heavy-duty environments. Both materials provide excellent corrosion resistance, but zinc plates are favored where structural strength and long-term durability are critical.

Cost Analysis: Zinc Sheet vs Zinc Plate

Zinc sheets generally offer a more cost-effective solution than zinc plates due to their thinner gauge and ease of fabrication, reducing material and labor expenses. Zinc plates, being thicker and heavier, incur higher raw material costs and increased transportation fees, impacting overall project budgets. For applications requiring durable, heavy-duty zinc components, the initial investment in zinc plates justifies the enhanced strength and longevity compared to thinner zinc sheets.

Fabrication and Workability Differences

Zinc sheets offer superior flexibility and ease of shaping, making them ideal for intricate fabrication processes such as bending, folding, and stamping in architectural applications. Zinc plates, being thicker and denser, provide enhanced strength and durability but require more specialized tools and techniques for cutting and forming, suitable for heavy-duty industrial uses. The workability of zinc sheets supports precision craftsmanship, whereas zinc plates are preferred when structural integrity and resistance to deformation under load are critical.

Corrosion Resistance Performance

Zinc sheets and zinc plates both provide excellent corrosion resistance due to their natural ability to form a protective oxide layer that prevents rust and deterioration. Zinc sheets, typically thinner and more flexible, offer superior uniformity in corrosion protection for applications like roofing and cladding. Zinc plates, being thicker and denser, excel in heavy-duty environments where extended exposure to corrosive elements requires enhanced durability.

Choosing the Right Zinc Material for Your Project

Zinc sheets offer superior flexibility and are ideal for applications requiring easy bending and shaping, such as roofing and cladding, while zinc plates provide greater thickness and strength, suitable for heavy-duty construction and industrial uses. Consider the specific project's structural demands and environmental exposure when selecting between zinc sheet and plate to ensure durability and performance. Using galvanized zinc for corrosion resistance can enhance longevity, especially in outdoor or marine environments.

Zinc Sheet vs Zinc Plate Infographic

materialdif.com

materialdif.com