Passivated zinc features a protective coating that enhances corrosion resistance, making it ideal for long-term applications in pet products exposed to moisture. Non-passivated zinc lacks this protective layer, resulting in faster oxidation and potential degradation of the material. Choosing passivated zinc ensures greater durability and safety in pet accessories compared to non-passivated alternatives.

Table of Comparison

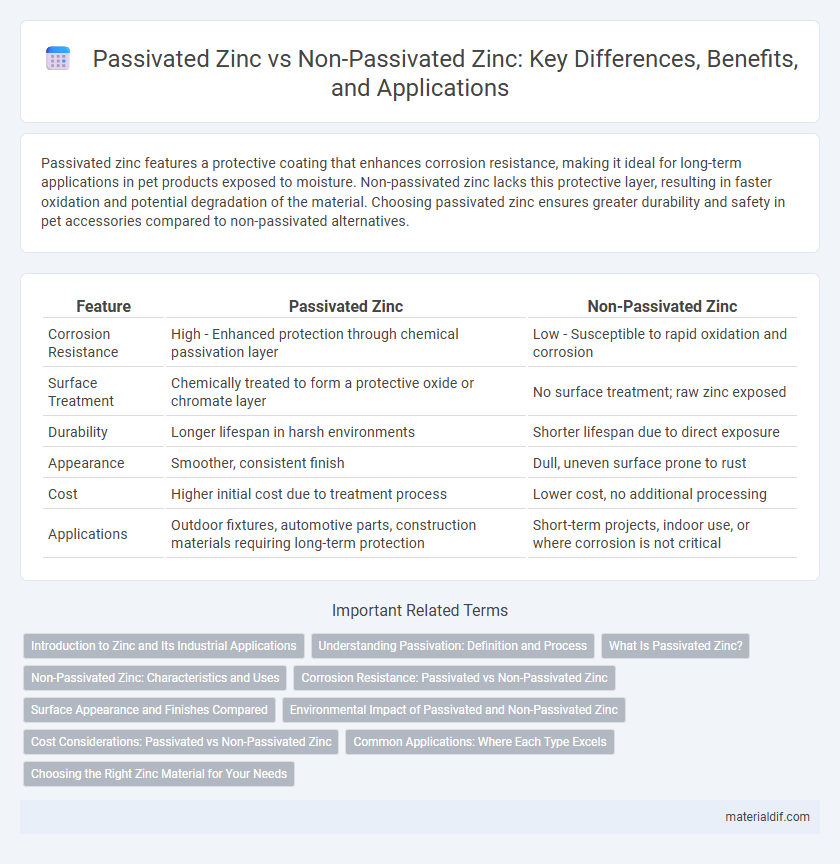

| Feature | Passivated Zinc | Non-Passivated Zinc |

|---|---|---|

| Corrosion Resistance | High - Enhanced protection through chemical passivation layer | Low - Susceptible to rapid oxidation and corrosion |

| Surface Treatment | Chemically treated to form a protective oxide or chromate layer | No surface treatment; raw zinc exposed |

| Durability | Longer lifespan in harsh environments | Shorter lifespan due to direct exposure |

| Appearance | Smoother, consistent finish | Dull, uneven surface prone to rust |

| Cost | Higher initial cost due to treatment process | Lower cost, no additional processing |

| Applications | Outdoor fixtures, automotive parts, construction materials requiring long-term protection | Short-term projects, indoor use, or where corrosion is not critical |

Introduction to Zinc and Its Industrial Applications

Zinc is a critical industrial metal primarily used for galvanizing steel to prevent corrosion, manufacturing alloys such as brass, and in die-casting components for automotive and electronics industries. Passivated zinc features a protective chemical layer that enhances corrosion resistance and prolongs the lifespan of zinc-coated products, making it highly valuable in infrastructure and construction. Non-passivated zinc lacks this protective coating, which can lead to faster oxidation and diminished durability in harsh environments.

Understanding Passivation: Definition and Process

Passivation of zinc involves creating a protective oxide or other chemical layer on its surface to enhance corrosion resistance and durability. This process typically occurs through chemical treatments or exposure to specific environments, forming a thin, inert film that prevents oxidation and decay. Non-passivated zinc lacks this protective layer, making it more susceptible to rust and environmental degradation.

What Is Passivated Zinc?

Passivated zinc is zinc metal treated with a protective coating to prevent oxidation and corrosion, enhancing its durability and lifespan in various applications. This coating typically involves a thin, transparent chemical layer such as chromate or phosphate, which acts as a barrier against environmental factors like moisture and air. In contrast, non-passivated zinc lacks this protective layer, making it more susceptible to rust and degradation over time.

Non-Passivated Zinc: Characteristics and Uses

Non-passivated zinc has a highly reactive surface prone to rapid oxidation and corrosion compared to passivated zinc, which has a protective oxide layer. It is commonly used in galvanizing steel for temporary protection during fabrication or welding processes where long-term durability is not critical. Non-passivated zinc's increased reactivity enhances its sacrificial anode properties in cathodic protection but requires careful handling to prevent premature degradation.

Corrosion Resistance: Passivated vs Non-Passivated Zinc

Passivated zinc offers superior corrosion resistance compared to non-passivated zinc due to the protective oxide layer formed during passivation, which significantly reduces oxidation and rust formation. Non-passivated zinc lacks this protective barrier, making it more susceptible to environmental factors such as moisture and air pollutants that accelerate corrosion. Studies show passivated zinc can extend the lifespan of metal components by up to 50% in harsh conditions versus non-passivated alternatives.

Surface Appearance and Finishes Compared

Passivated zinc exhibits a smooth, glossy surface finish with enhanced corrosion resistance due to the protective chemical layer, while non-passivated zinc tends to have a duller, matte appearance prone to oxidation and rust over time. The passivation process significantly improves surface durability, reducing maintenance needs and extending the lifespan of metal components. Non-passivated zinc may require additional treatments or coatings to achieve similar aesthetic and protective qualities.

Environmental Impact of Passivated and Non-Passivated Zinc

Passivated zinc significantly reduces environmental pollution by forming a protective oxide layer that prevents zinc runoff into soil and water, thereby minimizing toxic heavy metal contamination. Non-passivated zinc tends to corrode and leach into ecosystems, contributing to harmful bioaccumulation and negatively affecting aquatic life and soil quality. Studies show that passivation extends zinc's durability and mitigates ecological risks, making it a more sustainable option for industrial applications.

Cost Considerations: Passivated vs Non-Passivated Zinc

Passivated zinc incurs higher initial costs due to the additional chemical treatment that enhances corrosion resistance, extending the lifespan of coated materials. Non-passivated zinc offers lower upfront expenses but may require more frequent maintenance or replacement because it lacks protective surface layers. Evaluating total cost of ownership favors passivated zinc in applications demanding long-term durability despite higher initial investment.

Common Applications: Where Each Type Excels

Passivated zinc, with its enhanced corrosion resistance, is commonly used in automotive parts, electronics, and construction materials where longevity and environmental exposure are critical factors. Non-passivated zinc excels in applications such as galvanizing steel, sacrificial anodes, and industrial machinery where cost-effectiveness and basic corrosion protection are prioritized. Understanding the distinct protective coatings enables optimized material selection for durability or economic efficiency in manufacturing.

Choosing the Right Zinc Material for Your Needs

Passivated zinc offers superior corrosion resistance through a protective oxide layer, making it ideal for outdoor and high-moisture environments where durability is critical. Non-passivated zinc, while more cost-effective, lacks this protective layer and is better suited for indoor applications or conditions with minimal exposure to corrosive elements. Selecting the right zinc material depends on balancing budget constraints with environmental exposure and required longevity.

Passivated Zinc vs Non-Passivated Zinc Infographic

materialdif.com

materialdif.com