Zinc plating involves applying a thin layer of zinc to metal surfaces to provide corrosion resistance and a smooth, aesthetic finish, making it ideal for small components and low-wear applications. Galvanization, typically done through hot-dip processes, creates a thicker zinc coating that offers superior protection for outdoor structures and heavy-duty uses exposed to harsh environments. Choosing between zinc plating and galvanization depends on the required durability, environmental conditions, and the size or complexity of the metal parts.

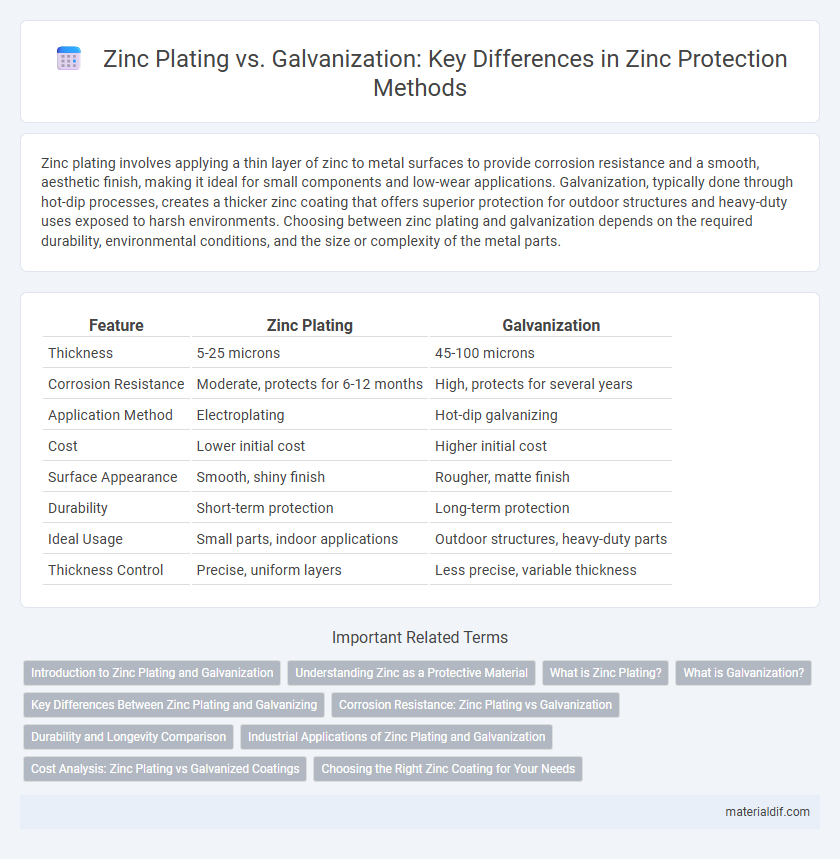

Table of Comparison

| Feature | Zinc Plating | Galvanization |

|---|---|---|

| Thickness | 5-25 microns | 45-100 microns |

| Corrosion Resistance | Moderate, protects for 6-12 months | High, protects for several years |

| Application Method | Electroplating | Hot-dip galvanizing |

| Cost | Lower initial cost | Higher initial cost |

| Surface Appearance | Smooth, shiny finish | Rougher, matte finish |

| Durability | Short-term protection | Long-term protection |

| Ideal Usage | Small parts, indoor applications | Outdoor structures, heavy-duty parts |

| Thickness Control | Precise, uniform layers | Less precise, variable thickness |

Introduction to Zinc Plating and Galvanization

Zinc plating involves electroplating a thin layer of zinc onto metal surfaces to provide corrosion resistance and an attractive finish. Galvanization typically refers to hot-dip galvanizing, where steel or iron is coated with a thicker, more durable layer of zinc by immersing the metal in molten zinc. Both processes enhance metal protection but differ in coating thickness, durability, and application methods.

Understanding Zinc as a Protective Material

Zinc plating involves applying a thin layer of zinc onto the surface of a metal to provide corrosion resistance through sacrificial protection, whereas galvanization typically refers to a thicker, more durable zinc coating often applied by hot-dip methods. Zinc acts as a protective material by forming a stable, adherent oxide layer that prevents further oxidation of the underlying metal. The effectiveness of zinc in corrosion protection depends on coating thickness, application process, and environmental exposure, with galvanization offering superior long-term durability compared to zinc plating.

What is Zinc Plating?

Zinc plating is a process that involves electrochemically coating a metal, typically steel or iron, with a thin layer of zinc to provide corrosion resistance and enhance appearance. This method creates a uniform, smooth surface that protects the underlying metal from rust by acting as a sacrificial anode. Zinc plating is widely used in automotive, hardware, and electronics industries for its cost-effectiveness and ability to improve metal durability.

What is Galvanization?

Galvanization is the process of applying a protective zinc coating to steel or iron to prevent rusting. This method typically involves hot-dip galvanizing, where the metal is submerged in molten zinc, creating a durable, corrosion-resistant layer. Galvanized steel is widely used in construction, automotive, and industrial applications due to its long-lasting defense against environmental elements.

Key Differences Between Zinc Plating and Galvanizing

Zinc plating involves applying a thin layer of zinc through electroplating to protect metal surfaces from corrosion, while galvanization typically uses a thicker, hot-dip zinc coating for enhanced durability. Zinc plating provides a more decorative, smooth finish ideal for smaller components, whereas galvanizing offers superior corrosion resistance suitable for outdoor and heavy-duty applications. The methods differ in coating thickness, corrosion protection longevity, and typical uses within industries such as automotive, construction, and manufacturing.

Corrosion Resistance: Zinc Plating vs Galvanization

Zinc plating provides a thin layer of zinc that offers moderate corrosion resistance, ideal for indoor or less harsh environments. Galvanization involves a thicker zinc coating that creates a robust barrier against corrosion, significantly extending the lifespan of steel in outdoor or highly corrosive settings. The superior protection of galvanization makes it the preferred method for heavy-duty applications requiring long-term durability against rust and weather exposure.

Durability and Longevity Comparison

Zinc plating provides a thin, uniform coating that offers moderate corrosion resistance primarily for indoor applications, with durability typically lasting 6 to 12 months outdoors. Galvanization, especially hot-dip galvanizing, creates a thick, robust zinc outer layer that can withstand harsh environmental conditions, extending metal lifespan to 50 years or more. The superior longevity of galvanization makes it ideal for heavy-duty and outdoor use where long-term protection against rust and corrosion is critical.

Industrial Applications of Zinc Plating and Galvanization

Zinc plating provides a thin, uniform coating ideal for small automotive parts and fasteners requiring corrosion resistance and enhanced aesthetics, commonly used in electronics and hardware manufacturing. Galvanization, particularly hot-dip galvanizing, applies a thicker, robust zinc layer suited for heavy-duty industrial applications like structural steel, pipelines, and agricultural equipment exposed to harsh environments. Both processes extend metal lifespan by preventing oxidation, but zinc plating is favored for precision components, while galvanization dominates large-scale infrastructure due to superior durability.

Cost Analysis: Zinc Plating vs Galvanized Coatings

Zinc plating typically incurs lower initial costs compared to galvanization due to less material usage and simpler application processes, making it economical for small-scale or precision parts. Galvanized coatings, while more expensive upfront, offer superior corrosion resistance and longer lifespan, reducing maintenance and replacement costs over time. Cost analysis must consider the total lifecycle expenses, including durability, environmental exposure, and application scale to determine the most cost-effective zinc coating method.

Choosing the Right Zinc Coating for Your Needs

Zinc plating offers a thinner, more aesthetically pleasing finish ideal for indoor applications where corrosion resistance is moderate, while galvanization provides a thicker, more durable zinc coating suited for outdoor exposure and harsh environments. Selecting the right zinc coating depends on factors such as the environmental conditions, desired lifespan, and budget constraints. Considering corrosion resistance standards like ASTM B633 for zinc plating and ASTM A123 for galvanization ensures optimal protection and performance.

Zinc Plating vs Galvanization Infographic

materialdif.com

materialdif.com