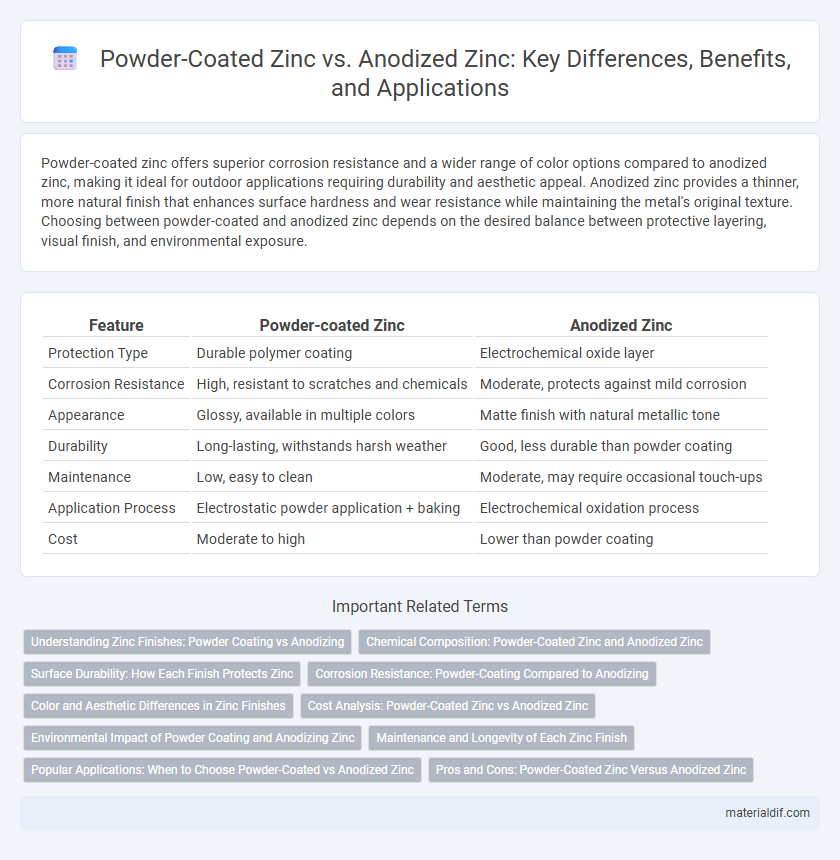

Powder-coated zinc offers superior corrosion resistance and a wider range of color options compared to anodized zinc, making it ideal for outdoor applications requiring durability and aesthetic appeal. Anodized zinc provides a thinner, more natural finish that enhances surface hardness and wear resistance while maintaining the metal's original texture. Choosing between powder-coated and anodized zinc depends on the desired balance between protective layering, visual finish, and environmental exposure.

Table of Comparison

| Feature | Powder-coated Zinc | Anodized Zinc |

|---|---|---|

| Protection Type | Durable polymer coating | Electrochemical oxide layer |

| Corrosion Resistance | High, resistant to scratches and chemicals | Moderate, protects against mild corrosion |

| Appearance | Glossy, available in multiple colors | Matte finish with natural metallic tone |

| Durability | Long-lasting, withstands harsh weather | Good, less durable than powder coating |

| Maintenance | Low, easy to clean | Moderate, may require occasional touch-ups |

| Application Process | Electrostatic powder application + baking | Electrochemical oxidation process |

| Cost | Moderate to high | Lower than powder coating |

Understanding Zinc Finishes: Powder Coating vs Anodizing

Powder-coated zinc offers a durable, colorful finish by applying a dry powder cured under heat, creating a thick protective layer resistant to corrosion and weathering. Anodized zinc undergoes an electrochemical process that enhances the natural oxide layer, improving corrosion resistance while maintaining a metallic appearance with increased surface hardness. Choosing between powder-coated and anodized zinc depends on desired aesthetic, durability requirements, and environmental exposure, with powder coating providing more color options and anodizing offering a subtle, corrosion-resistant finish.

Chemical Composition: Powder-Coated Zinc and Anodized Zinc

Powder-coated zinc involves applying a protective polymer resin over zinc substrates, offering enhanced corrosion resistance through a physical barrier rather than altering the underlying zinc's chemical structure. Anodized zinc undergoes an electrochemical process that thickens the natural oxide layer on the zinc surface, enriching its chemical composition with zinc oxide and hydroxide compounds for improved durability. The powder-coated layer primarily consists of polymer compounds combined with zinc, while anodized zinc's surface chemistry is predominantly zinc oxide-based, providing distinct protective qualities.

Surface Durability: How Each Finish Protects Zinc

Powder-coated zinc provides a robust, thick layer that resists scratches, corrosion, and UV degradation, extending the metal's lifespan in harsh environments. Anodized zinc forms a thin, but chemically bonded oxide layer, enhancing corrosion resistance and surface hardness while maintaining the metal's natural appearance. Both finishes improve surface durability, with powder coating offering superior protection against physical damage and anodizing delivering enhanced chemical resistance.

Corrosion Resistance: Powder-Coating Compared to Anodizing

Powder-coated zinc offers a robust protective layer that significantly enhances corrosion resistance by creating a durable, impermeable barrier against moisture and environmental pollutants. In contrast, anodized zinc improves corrosion resistance by forming a controlled oxide layer that integrates with the metal surface but may be more susceptible to scratching and wear over time. For applications requiring long-lasting protection in harsh environments, powder-coated zinc generally outperforms anodized zinc in maintaining surface integrity and preventing oxidation.

Color and Aesthetic Differences in Zinc Finishes

Powder-coated zinc offers a wider range of color options and a thicker, more uniform finish that enhances durability and resistance to chipping compared to anodized zinc. Anodized zinc provides a natural metallic sheen with subtle color variations, maintaining the zinc's inherent texture and offering a more understated aesthetic appeal. The choice between powder-coated and anodized zinc depends on desired color vibrancy and surface smoothness, with powder coating excelling in vivid, consistent colors and anodizing preserving a sleek, metallic appearance.

Cost Analysis: Powder-Coated Zinc vs Anodized Zinc

Powder-coated zinc generally incurs lower upfront costs compared to anodized zinc due to its simpler application process and faster curing times, making it economically attractive for large-scale projects. Anodized zinc, while typically more expensive initially, offers enhanced durability and corrosion resistance, potentially reducing long-term maintenance expenses and replacements. Evaluating total cost of ownership reveals that powder-coated zinc suits budget-conscious applications, whereas anodized zinc provides greater value in environments demanding superior longevity.

Environmental Impact of Powder Coating and Anodizing Zinc

Powder-coated zinc employs a dry powder application that minimizes volatile organic compound (VOC) emissions, making it a more environmentally friendly option compared to traditional liquid coatings. Anodizing zinc enhances corrosion resistance through an electrochemical process that generates minimal hazardous waste but involves significant water and energy consumption. Both methods improve zinc's durability and lifespan, reducing the frequency of replacement and associated environmental costs.

Maintenance and Longevity of Each Zinc Finish

Powder-coated zinc offers a highly durable protective layer resistant to corrosion, scratches, and UV exposure, significantly reducing maintenance requirements over time. Anodized zinc, through its electrochemical process, forms a thin, durable oxide layer that enhances corrosion resistance but may require periodic cleaning and potential re-anodizing in harsh environments. While powder coating generally provides longer-lasting protection with minimal upkeep, anodized zinc maintains a natural metallic appearance favored for applications demanding both aesthetics and moderate maintenance.

Popular Applications: When to Choose Powder-Coated vs Anodized Zinc

Powder-coated zinc offers superior corrosion resistance and vibrant color options, making it ideal for outdoor architectural elements, automotive parts, and industrial equipment exposed to harsh environments. Anodized zinc provides enhanced surface hardness and a natural metallic finish suitable for electronic housings, decorative hardware, and consumer goods requiring durable yet aesthetically subtle protection. Choosing between powder-coated and anodized zinc depends on the need for color variety and extreme protection versus a sleek, wear-resistant surface with moderate corrosion defense.

Pros and Cons: Powder-Coated Zinc Versus Anodized Zinc

Powder-coated zinc offers superior corrosion resistance and a wider range of color options compared to anodized zinc, making it ideal for architectural applications requiring durable and aesthetic finishes. Anodized zinc provides a natural metallic appearance with excellent scratch and wear resistance but is generally less flexible in color customization and may require more maintenance in harsh environments. Choosing between powder-coated and anodized zinc depends on specific project needs such as durability, appearance, and environmental exposure.

Powder-coated Zinc vs Anodized Zinc Infographic

materialdif.com

materialdif.com