Zinc anodes offer superior corrosion resistance and are more effective in preventing galvanic corrosion in saltwater environments compared to aluminum anodes. While aluminum anodes are lighter and cost-effective, zinc anodes provide longer-lasting protection and better performance in cold water conditions. Choosing between zinc and aluminum anodes depends on the specific marine environment and vessel requirements for optimal cathodic protection.

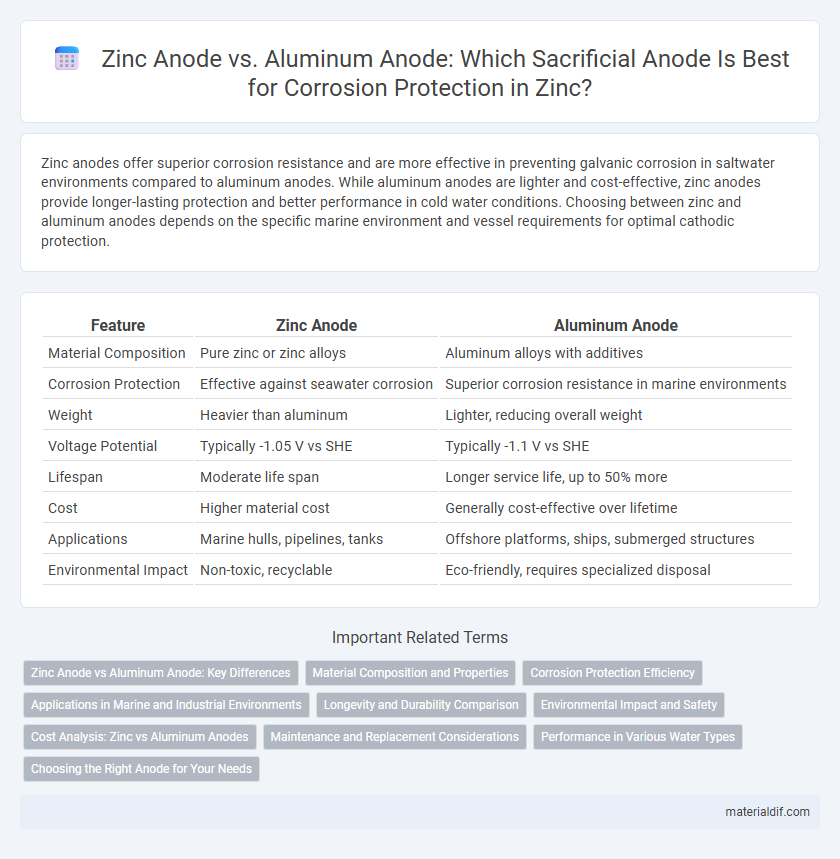

Table of Comparison

| Feature | Zinc Anode | Aluminum Anode |

|---|---|---|

| Material Composition | Pure zinc or zinc alloys | Aluminum alloys with additives |

| Corrosion Protection | Effective against seawater corrosion | Superior corrosion resistance in marine environments |

| Weight | Heavier than aluminum | Lighter, reducing overall weight |

| Voltage Potential | Typically -1.05 V vs SHE | Typically -1.1 V vs SHE |

| Lifespan | Moderate life span | Longer service life, up to 50% more |

| Cost | Higher material cost | Generally cost-effective over lifetime |

| Applications | Marine hulls, pipelines, tanks | Offshore platforms, ships, submerged structures |

| Environmental Impact | Non-toxic, recyclable | Eco-friendly, requires specialized disposal |

Zinc Anode vs Aluminum Anode: Key Differences

Zinc anodes provide superior corrosion resistance in marine environments compared to aluminum anodes, making them ideal for saltwater applications. Aluminum anodes offer lighter weight and cost efficiency with a higher electrochemical capacity but may underperform in highly alkaline conditions. The choice between zinc and aluminum anodes depends on water salinity, temperature, and specific galvanic protection requirements.

Material Composition and Properties

Zinc anodes primarily consist of high-purity zinc alloys known for excellent corrosion resistance and moderate electrochemical potential, making them suitable for marine and cathodic protection applications. Aluminum anodes, composed of aluminum-zinc-indium alloys, offer higher electrochemical efficiency, lower density, and superior current output compared to zinc, enhancing performance in saltwater environments. The material composition differences result in aluminum anodes delivering longer service life and better conductivity, whereas zinc anodes provide stable protection in varied water conditions due to their uniform dissolution properties.

Corrosion Protection Efficiency

Zinc anodes provide superior corrosion protection efficiency in marine environments due to their higher electrochemical potential, ensuring consistent sacrificial action on steel structures. Aluminum anodes offer lightweight advantages but may exhibit lower current capacity and reduced performance in low-temperature or high-salinity waters. Selection between zinc and aluminum anodes depends on specific environmental conditions and required longevity for effective cathodic protection systems.

Applications in Marine and Industrial Environments

Zinc anodes are widely used in marine and industrial environments for cathodic protection due to their superior performance in saltwater conditions, effectively preventing corrosion on ship hulls and offshore structures. Aluminum anodes offer a lighter, high-capacity alternative preferred in warmer waters and less aggressive environments, providing longer service life and cost efficiency in industrial applications such as pipelines and storage tanks. Both materials are integral for corrosion control, but zinc is favored for its stable electrochemical properties in harsh marine settings.

Longevity and Durability Comparison

Zinc anodes typically offer superior longevity in marine environments due to their slower corrosion rate compared to aluminum anodes, which tend to deteriorate faster when exposed to saltwater. Aluminum anodes, while more cost-effective and lighter, may sacrifice durability and require more frequent replacement to maintain effective corrosion protection. The choice between zinc and aluminum anodes depends largely on specific environmental conditions and maintenance schedules, with zinc providing a more robust option for long-term durability in harsh saltwater applications.

Environmental Impact and Safety

Zinc anodes exhibit lower toxicity and reduce heavy metal pollution compared to aluminum anodes, making them a more environmentally friendly option in marine and industrial applications. Aluminum anodes pose higher risks of releasing hazardous aluminum compounds into aquatic ecosystems, potentially harming marine life and disrupting ecological balance. Safety considerations favor zinc anodes due to their more predictable corrosion behavior and lower risk of sparks or explosions during handling and installation.

Cost Analysis: Zinc vs Aluminum Anodes

Zinc anodes typically exhibit a higher initial cost compared to aluminum anodes due to material composition and manufacturing processes, yet they offer longer service life in marine environments which can offset expenses over time. Aluminum anodes are generally more cost-effective upfront and lighter, reducing handling and installation costs, but may require more frequent replacement depending on water conditions and current density. Evaluating total lifecycle cost including maintenance and replacement frequency reveals aluminum anodes as economically favorable in low-salinity waters, while zinc anodes perform better in high-salinity or polluted waters despite their higher price.

Maintenance and Replacement Considerations

Zinc anodes exhibit slower corrosion rates compared to aluminum anodes, resulting in less frequent maintenance and replacement intervals. Aluminum anodes can experience rapid consumption in aggressive marine environments, necessitating more regular inspections to ensure protection efficacy. Proper selection between zinc and aluminum anodes depends on environmental factors and cost-benefit analysis regarding maintenance frequency and operational downtime.

Performance in Various Water Types

Zinc anodes exhibit superior corrosion resistance in saltwater environments due to their stable electrochemical properties, making them ideal for marine applications. Aluminum anodes perform better in brackish and freshwater conditions, offering higher current capacity and longer service life with less weight. Selection between zinc and aluminum anodes depends on specific water chemistry, temperature, and salinity levels to optimize cathodic protection efficiency.

Choosing the Right Anode for Your Needs

Zinc anodes offer superior corrosion resistance in seawater environments, making them ideal for saltwater applications, while aluminum anodes provide higher electrochemical capacity and are lighter, suitable for freshwater and brackish water conditions. Selecting the right anode depends on factors such as water type, temperature, and the metal structure being protected. Evaluating environmental conditions and compatibility ensures optimal cathodic protection and extends the lifespan of marine vessels or infrastructure.

Zinc anode vs Aluminum anode Infographic

materialdif.com

materialdif.com