Machined titanium offers superior strength and precision compared to cast titanium, making it ideal for high-performance pet products that require durability and exact fit. Cast titanium, while more cost-effective and versatile in complex shapes, may have slight variations in density and strength due to its forming process. Choosing machined titanium ensures enhanced reliability and longevity in pet accessories exposed to rigorous use.

Table of Comparison

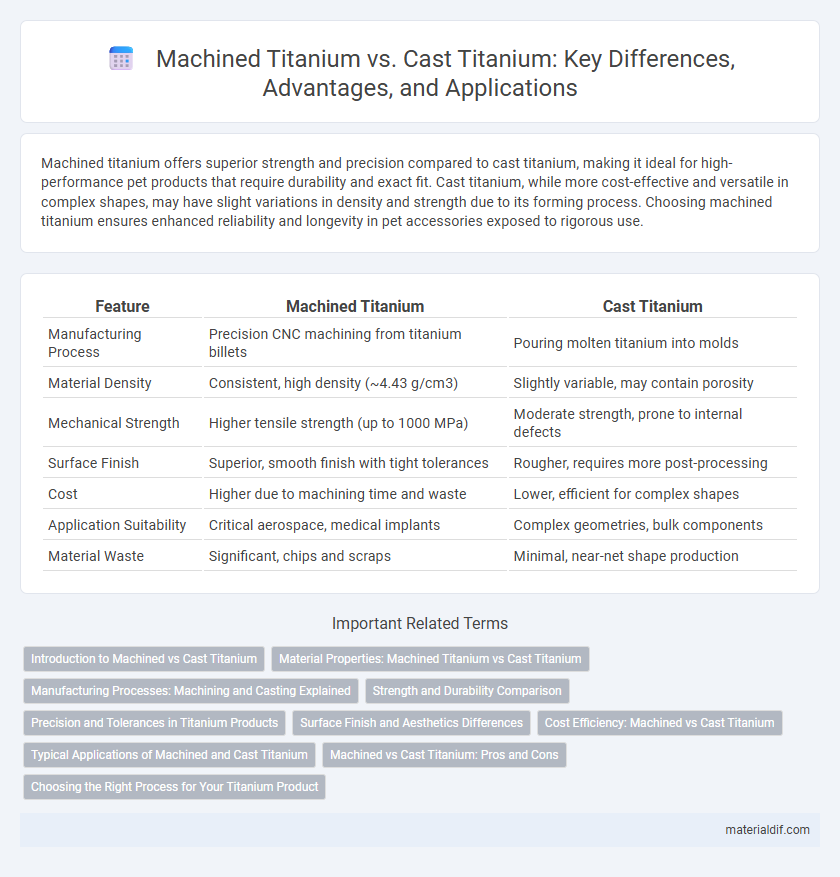

| Feature | Machined Titanium | Cast Titanium |

|---|---|---|

| Manufacturing Process | Precision CNC machining from titanium billets | Pouring molten titanium into molds |

| Material Density | Consistent, high density (~4.43 g/cm3) | Slightly variable, may contain porosity |

| Mechanical Strength | Higher tensile strength (up to 1000 MPa) | Moderate strength, prone to internal defects |

| Surface Finish | Superior, smooth finish with tight tolerances | Rougher, requires more post-processing |

| Cost | Higher due to machining time and waste | Lower, efficient for complex shapes |

| Application Suitability | Critical aerospace, medical implants | Complex geometries, bulk components |

| Material Waste | Significant, chips and scraps | Minimal, near-net shape production |

Introduction to Machined vs Cast Titanium

Machined titanium is produced by precisely cutting and shaping solid titanium billets, resulting in high strength and superior surface finishes ideal for aerospace and medical applications. Cast titanium is formed by pouring molten titanium into molds, allowing complex geometries but often with reduced mechanical properties due to porosity and grain structure inconsistencies. Understanding the differences between these manufacturing processes helps optimize material performance and cost-efficiency in engineering applications.

Material Properties: Machined Titanium vs Cast Titanium

Machined titanium exhibits superior mechanical strength and surface finish compared to cast titanium, resulting from its dense, homogeneous microstructure achieved through CNC machining from titanium billets. Cast titanium, formed by pouring molten metal into molds, tends to have a more porous structure, which can reduce fatigue resistance and increase susceptibility to micro-defects. The choice between machined and cast titanium heavily influences corrosion resistance and tensile properties, with machined titanium generally providing enhanced durability in high-stress or biomedical applications.

Manufacturing Processes: Machining and Casting Explained

Machined titanium involves shaping solid titanium blocks through precision cutting tools, offering superior surface finish and tight tolerances for aerospace and medical components. Cast titanium is produced by melting titanium alloy and pouring it into molds, enabling complex geometries and cost-effective mass production but with coarser grain structures. Understanding machining's material removal and casting's solidification processes is crucial for selecting the appropriate manufacturing method based on mechanical performance and design complexity.

Strength and Durability Comparison

Machined titanium exhibits superior strength and durability compared to cast titanium due to its homogeneous microstructure and precision manufacturing process, which reduces internal defects. Cast titanium, formed by pouring molten metal into molds, often contains porosity and grain boundary weaknesses that can compromise its mechanical properties. The enhanced tensile strength and fatigue resistance of machined titanium make it the preferred choice for high-performance applications requiring long-term reliability.

Precision and Tolerances in Titanium Products

Machined titanium offers superior precision and tighter tolerances compared to cast titanium due to its controlled subtractive manufacturing process, allowing intricate designs with exact dimensions. Cast titanium, while beneficial for complex shapes, tends to have higher dimensional variability and less uniformity because of shrinkage and solidification inconsistencies. Industries demanding high accuracy like aerospace and medical implants favor machined titanium for critical components requiring exact fit and performance.

Surface Finish and Aesthetics Differences

Machined titanium offers a smoother, more precise surface finish with finer details, resulting in a consistently polished and refined aesthetic ideal for high-end applications. Cast titanium, while still strong and durable, typically exhibits a rougher texture with minor surface irregularities due to the molding process, which can impact the overall visual uniformity. The enhanced surface finish of machined titanium allows for better customization and superior cosmetic appeal compared to the inherently textured appearance of cast titanium.

Cost Efficiency: Machined vs Cast Titanium

Machined titanium involves precision cutting from solid billets, leading to higher material waste and longer production times, which increases overall costs compared to cast titanium. Cast titanium, produced by pouring molten metal into molds, enables more complex shapes with minimal waste and faster turnaround, resulting in greater cost efficiency for large or intricate parts. For industries prioritizing budget and volume, cast titanium offers significant savings without compromising strength or corrosion resistance.

Typical Applications of Machined and Cast Titanium

Machined titanium is commonly used in aerospace, automotive, and medical device industries due to its precision, strength, and excellent surface finish, making it ideal for components like engine parts, surgical instruments, and prosthetics. Cast titanium finds typical applications in complex-shaped parts where intricate geometries are required, such as turbine blades, custom aerospace components, and automotive exhaust systems. Both methods leverage titanium's corrosion resistance and high strength-to-weight ratio, but machined titanium is preferred for tight-tolerance and high-performance parts while cast titanium suits bulkier, less dimensionally critical applications.

Machined vs Cast Titanium: Pros and Cons

Machined titanium offers superior dimensional accuracy and surface finish compared to cast titanium, making it ideal for high-precision applications in aerospace and medical implants. Cast titanium, while less expensive and capable of producing complex shapes with minimal material waste, often has inferior mechanical properties due to potential porosity and grain structure inconsistencies. Choosing machined titanium ensures enhanced strength and fatigue resistance, whereas cast titanium provides cost-effective solutions for large or intricate components with moderate performance requirements.

Choosing the Right Process for Your Titanium Product

Machined titanium offers precise dimensional accuracy and superior surface finish ideal for complex, high-performance aerospace and medical components. Cast titanium provides cost-effective production for larger, less intricate parts, with excellent mechanical properties suitable for automotive and industrial applications. Selecting the right process depends on balancing design complexity, production volume, and performance requirements to optimize material properties and manufacturing efficiency.

Machined Titanium vs Cast Titanium Infographic

materialdif.com

materialdif.com