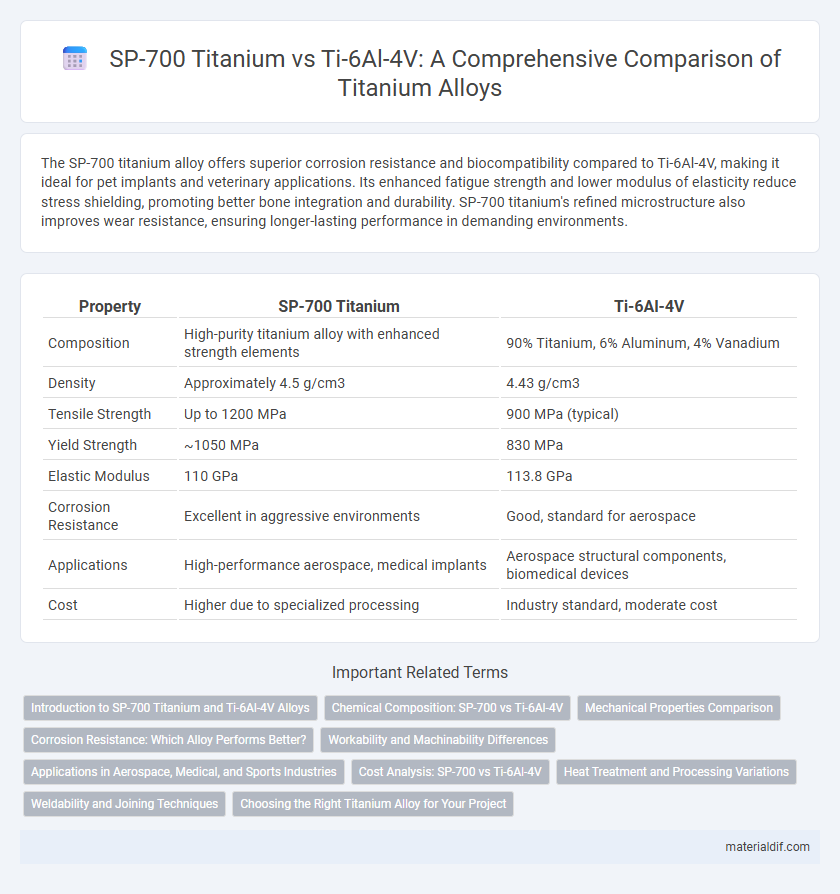

The SP-700 titanium alloy offers superior corrosion resistance and biocompatibility compared to Ti-6Al-4V, making it ideal for pet implants and veterinary applications. Its enhanced fatigue strength and lower modulus of elasticity reduce stress shielding, promoting better bone integration and durability. SP-700 titanium's refined microstructure also improves wear resistance, ensuring longer-lasting performance in demanding environments.

Table of Comparison

| Property | SP-700 Titanium | Ti-6Al-4V |

|---|---|---|

| Composition | High-purity titanium alloy with enhanced strength elements | 90% Titanium, 6% Aluminum, 4% Vanadium |

| Density | Approximately 4.5 g/cm3 | 4.43 g/cm3 |

| Tensile Strength | Up to 1200 MPa | 900 MPa (typical) |

| Yield Strength | ~1050 MPa | 830 MPa |

| Elastic Modulus | 110 GPa | 113.8 GPa |

| Corrosion Resistance | Excellent in aggressive environments | Good, standard for aerospace |

| Applications | High-performance aerospace, medical implants | Aerospace structural components, biomedical devices |

| Cost | Higher due to specialized processing | Industry standard, moderate cost |

Introduction to SP-700 Titanium and Ti-6Al-4V Alloys

SP-700 Titanium is a high-strength, heat-treatable titanium alloy recognized for superior mechanical properties and corrosion resistance, making it ideal for aerospace and marine applications. Ti-6Al-4V, an alpha-beta titanium alloy, is the most widely used titanium grade offering a balanced combination of strength, toughness, and weldability. Both alloys are critical in advanced engineering, with SP-700 delivering higher strength at elevated temperatures compared to the versatile and cost-effective Ti-6Al-4V.

Chemical Composition: SP-700 vs Ti-6Al-4V

SP-700 titanium alloy features a chemical composition primarily consisting of 5% aluminum, 2.5% tin, 1% zirconium, and 0.25% ruthenium, offering enhanced corrosion resistance and strength compared to Ti-6Al-4V. Ti-6Al-4V alloy contains approximately 6% aluminum and 4% vanadium, with the balance being titanium, providing a high strength-to-weight ratio widely used in aerospace and medical applications. The key difference lies in SP-700's inclusion of tin and ruthenium, which improve its performance in aggressive environments versus the traditional aluminum and vanadium in Ti-6Al-4V.

Mechanical Properties Comparison

SP-700 titanium exhibits superior tensile strength and fatigue resistance compared to Ti-6Al-4V, making it ideal for high-performance aerospace applications. While Ti-6Al-4V maintains excellent corrosion resistance and good ductility, SP-700 offers enhanced fracture toughness and higher yield strength levels. These mechanical property differences enable engineers to select SP-700 for components subjected to extreme stress and cyclic loading conditions.

Corrosion Resistance: Which Alloy Performs Better?

SP-700 titanium alloy exhibits superior corrosion resistance compared to Ti-6Al-4V due to its metastable beta-phase structure and enhanced alloying elements like molybdenum and chromium. The enhanced passivation layer in SP-700 provides better protection against chloride-induced pitting and crevice corrosion in aggressive environments. Ti-6Al-4V, despite widespread use, is more prone to localized corrosion, especially in marine and chemical applications where SP-700 demonstrates greater durability.

Workability and Machinability Differences

SP-700 Titanium exhibits superior workability compared to Ti-6Al-4V due to its enhanced ductility and lower strength at room temperature, allowing easier forming and shaping processes. In terms of machinability, Ti-6Al-4V presents more challenges because of its higher hardness and strength, resulting in increased tool wear and slower machining speeds. SP-700's improved microstructure facilitates smoother cutting operations and extended tool life during machining compared to the conventional Ti-6Al-4V alloy.

Applications in Aerospace, Medical, and Sports Industries

SP-700 titanium offers enhanced strength and fatigue resistance compared to Ti-6Al-4V, making it ideal for critical aerospace components such as airframe structures and engine parts. In the medical industry, SP-700's superior biocompatibility and corrosion resistance support its use in high-performance orthopedic implants and surgical instruments. The sports industry benefits from SP-700's lightweight and robust properties, particularly for high-end bicycle frames and golf club heads, outperforming traditional Ti-6Al-4V alloys.

Cost Analysis: SP-700 vs Ti-6Al-4V

SP-700 Titanium typically incurs higher production costs compared to Ti-6Al-4V due to its advanced alloy composition and specialized manufacturing processes. Ti-6Al-4V remains cost-effective for large-scale applications because of its widespread availability and established supply chains. Evaluating total life-cycle expenses, including machining and maintenance, reveals that SP-700 may offer cost benefits in performance-critical environments despite premium upfront pricing.

Heat Treatment and Processing Variations

SP-700 titanium offers superior heat treatment capabilities compared to Ti-6Al-4V, enabling enhanced strength and fatigue resistance through multiple aging cycles. SP-700's unique microstructure allows precise control during processing, resulting in improved mechanical properties and better fracture toughness. Ti-6Al-4V, while versatile, has more limited post-processing options, making SP-700 the preferred choice for high-performance aerospace and industrial applications requiring rigorous thermal treatments.

Weldability and Joining Techniques

SP-700 titanium exhibits superior weldability compared to Ti-6Al-4V due to its higher ductility and reduced susceptibility to cracking during welding processes. Advanced joining techniques such as electron beam welding and laser welding are more effective on SP-700, offering improved joint strength and reduced post-weld heat treatment requirements. In contrast, Ti-6Al-4V often necessitates controlled atmospheres and preheating to mitigate weld-related defects, impacting production efficiency.

Choosing the Right Titanium Alloy for Your Project

SP-700 titanium offers superior strength and fatigue resistance compared to the widely used Ti-6Al-4V alloy, making it ideal for high-stress aerospace and industrial applications. Ti-6Al-4V provides excellent corrosion resistance and lightweight properties, suitable for biomedical implants and general engineering projects. Selecting the right titanium alloy depends on balancing mechanical performance with environmental conditions and cost constraints specific to the project.

SP-700 Titanium vs Ti-6Al-4V Infographic

materialdif.com

materialdif.com