Rolled titanium features a smoother, more uniform surface finish due to the metal being passed through rollers under high pressure, enhancing its strength and fatigue resistance. Drawn titanium is produced by pulling the metal through a die, resulting in a more precise dimensional control and increased tensile strength. Choosing between rolled and drawn titanium depends on the specific application requirements, such as surface finish preferences and mechanical property priorities.

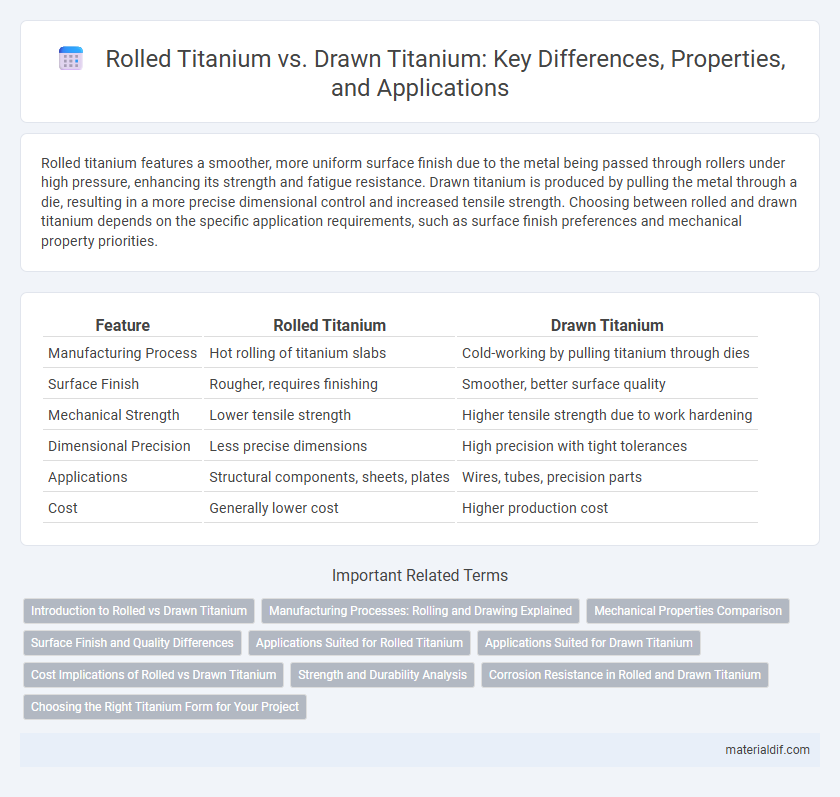

Table of Comparison

| Feature | Rolled Titanium | Drawn Titanium |

|---|---|---|

| Manufacturing Process | Hot rolling of titanium slabs | Cold-working by pulling titanium through dies |

| Surface Finish | Rougher, requires finishing | Smoother, better surface quality |

| Mechanical Strength | Lower tensile strength | Higher tensile strength due to work hardening |

| Dimensional Precision | Less precise dimensions | High precision with tight tolerances |

| Applications | Structural components, sheets, plates | Wires, tubes, precision parts |

| Cost | Generally lower cost | Higher production cost |

Introduction to Rolled vs Drawn Titanium

Rolled titanium is produced by passing titanium ingots through rollers to create sheets or plates, offering enhanced mechanical properties and surface finish suitable for aerospace and automotive applications. Drawn titanium is formed by pulling titanium rods or wire through dies, resulting in precise dimensions and improved strength used primarily in medical devices and industrial fasteners. Understanding the differences between rolled and drawn titanium is crucial for selecting the appropriate material based on mechanical requirements and manufacturing processes.

Manufacturing Processes: Rolling and Drawing Explained

Rolled titanium involves shaping titanium metal by passing it through a series of rollers to reduce thickness and improve uniformity, creating broad, flat sheets or plates with enhanced strength and surface finish. Drawn titanium is produced by pulling titanium rods or bars through a die to reduce diameter and increase length, resulting in precise, seamless shapes with improved mechanical properties and fine surface texture. Both processes optimize titanium's structural integrity and surface quality, catering to different industrial applications such as aerospace, medical implants, and automotive components.

Mechanical Properties Comparison

Rolled titanium typically exhibits improved ductility and uniform grain structure due to the hot or cold rolling process, enhancing its toughness and fatigue resistance. Drawn titanium, produced through cold drawing, generally offers higher tensile strength and better dimensional accuracy because of work hardening effects. The choice between rolled and drawn titanium depends on the required balance between mechanical strength and formability for specific industrial applications such as aerospace or biomedical implants.

Surface Finish and Quality Differences

Rolled titanium typically offers a smoother surface finish due to the compressive forces of rolling, which enhance its grain structure and reduce surface imperfections compared to drawn titanium. Drawn titanium, produced by pulling through dies, often exhibits a rougher texture with more visible marks and slight dimensional inconsistencies, affecting its aesthetic quality. These differences in surface finish significantly impact the material's suitability for applications requiring high-quality appearance and corrosion resistance.

Applications Suited for Rolled Titanium

Rolled titanium offers superior strength and flexibility, making it ideal for aerospace components, medical implants, and automotive parts requiring high durability and corrosion resistance. Its uniform grain structure enhances fatigue performance, which suits applications like aircraft fuselage skins and surgical instruments. Industries favor rolled titanium for manufacturing lightweight, robust parts subjected to dynamic stress and harsh environments.

Applications Suited for Drawn Titanium

Drawn titanium offers superior strength and enhanced dimensional precision compared to rolled titanium, making it ideal for aerospace fasteners, medical implants, and high-performance sporting equipment where tight tolerances are critical. Its refined grain structure and improved mechanical properties support applications requiring excellent fatigue resistance and corrosion durability. Due to its enhanced surface finish and uniformity, drawn titanium is preferred in precision engineering and critical load-bearing components.

Cost Implications of Rolled vs Drawn Titanium

Rolled titanium typically incurs lower production costs due to its simpler manufacturing process and higher material yield compared to drawn titanium, which requires more precise and time-intensive cold working methods. The increased labor and equipment expenses in drawn titanium production result in higher costs per unit, making it less economical for large-scale applications. Manufacturers often choose rolled titanium for budget-sensitive projects where cost-efficiency is critical, whereas drawn titanium is preferred for high-precision uses despite its premium pricing.

Strength and Durability Analysis

Rolled titanium exhibits improved grain structure uniformity, enhancing its tensile strength and impact resistance compared to drawn titanium, which tends to have anisotropic properties due to directional elongation during processing. The rolling process refines the microstructure, resulting in superior fatigue resistance and durability in high-stress applications. Drawn titanium, while offering precise dimensional control, may present lower overall mechanical strength and higher susceptibility to crack initiation under cyclic loading conditions.

Corrosion Resistance in Rolled and Drawn Titanium

Rolled titanium exhibits enhanced corrosion resistance due to its refined grain structure and uniform surface, which limits corrosion initiation sites. Drawn titanium, while also corrosion-resistant, may possess microstructural inconsistencies introduced during the drawing process that can affect surface passivation. In marine and chemical environments, rolled titanium typically outperforms drawn titanium in resisting pitting and crevice corrosion.

Choosing the Right Titanium Form for Your Project

Rolled titanium offers enhanced strength and uniformity, making it ideal for structural applications requiring high durability, while drawn titanium provides superior surface finish and precise dimensions, suited for intricate components and aerospace parts. Selecting the right titanium form depends on project requirements such as mechanical properties, surface quality, and fabrication processes, with rolled titanium favored for heavy-duty uses and drawn titanium for precision engineering. Understanding the specific demands of your project ensures optimal performance and cost-efficiency by leveraging the distinct advantages of rolled or drawn titanium forms.

Rolled Titanium vs Drawn Titanium Infographic

materialdif.com

materialdif.com