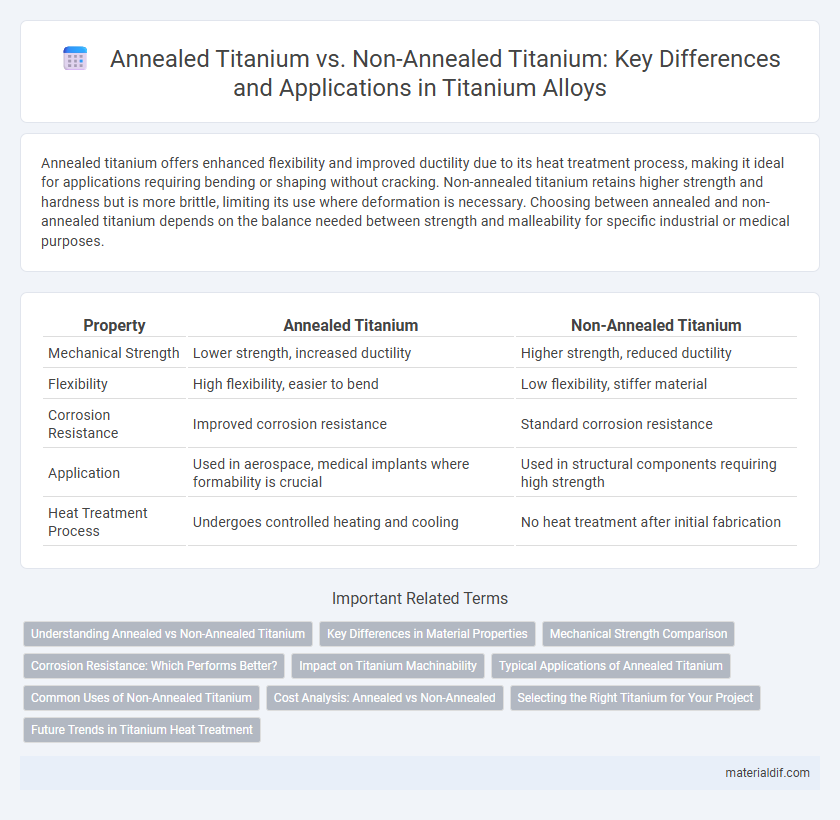

Annealed titanium offers enhanced flexibility and improved ductility due to its heat treatment process, making it ideal for applications requiring bending or shaping without cracking. Non-annealed titanium retains higher strength and hardness but is more brittle, limiting its use where deformation is necessary. Choosing between annealed and non-annealed titanium depends on the balance needed between strength and malleability for specific industrial or medical purposes.

Table of Comparison

| Property | Annealed Titanium | Non-Annealed Titanium |

|---|---|---|

| Mechanical Strength | Lower strength, increased ductility | Higher strength, reduced ductility |

| Flexibility | High flexibility, easier to bend | Low flexibility, stiffer material |

| Corrosion Resistance | Improved corrosion resistance | Standard corrosion resistance |

| Application | Used in aerospace, medical implants where formability is crucial | Used in structural components requiring high strength |

| Heat Treatment Process | Undergoes controlled heating and cooling | No heat treatment after initial fabrication |

Understanding Annealed vs Non-Annealed Titanium

Annealed titanium undergoes a heat treatment process that enhances its ductility and reduces internal stresses, making it more malleable and suitable for complex fabrication. Non-annealed titanium retains its original hardness and strength, offering superior resistance to deformation but less flexibility during forming. Understanding the differences between annealed and non-annealed titanium is crucial for selecting the right material based on mechanical performance and application requirements.

Key Differences in Material Properties

Annealed titanium exhibits enhanced ductility and improved corrosion resistance compared to non-annealed titanium, due to its heat treatment process that relieves internal stresses and refines grain structure. Non-annealed titanium retains higher tensile strength and hardness, making it suitable for applications requiring greater mechanical strength but less flexibility. The annealing process significantly affects titanium's microstructure, resulting in a balance between strength and formability tailored to specific industrial uses.

Mechanical Strength Comparison

Annealed titanium exhibits lower mechanical strength but enhanced ductility compared to non-annealed titanium, making it more suitable for applications requiring flexibility and formability. Non-annealed titanium retains higher tensile strength and hardness due to its work-hardened microstructure, providing superior resistance to deformation under stress. The choice between annealed and non-annealed titanium depends on the balance needed between strength and machinability for specific industrial uses.

Corrosion Resistance: Which Performs Better?

Annealed titanium exhibits superior corrosion resistance compared to non-annealed titanium due to its refined microstructure that reduces internal stresses and eliminates defects prone to corrosion initiation. The annealing process enhances the oxide layer's stability on titanium surfaces, providing better protection against aggressive environments such as seawater and chemical exposure. Non-annealed titanium, while strong, may have residual stresses and microstructural irregularities that can compromise long-term corrosion resistance performance.

Impact on Titanium Machinability

Annealed titanium exhibits improved machinability due to its reduced hardness and increased ductility, allowing cutting tools to wear less quickly and operate more efficiently. Non-annealed titanium, characterized by higher strength and hardness, poses greater challenges in machining with increased tool wear and slower cutting speeds. Understanding the heat treatment state of titanium is crucial for optimizing machining performance and extending tool life in manufacturing processes.

Typical Applications of Annealed Titanium

Annealed titanium is commonly used in aerospace components, medical implants, and chemical processing equipment due to its enhanced ductility and corrosion resistance. Its softer, more workable structure allows for easier shaping and welding compared to non-annealed titanium, making it ideal for applications requiring complex forms and tight tolerances. Typical industries utilizing annealed titanium prioritize these mechanical properties to improve performance and longevity in demanding environments.

Common Uses of Non-Annealed Titanium

Non-annealed titanium, known for its high strength and hardness, is commonly utilized in aerospace components, medical implants, and industrial machinery where durability is critical. Its untreated, cold-worked state offers superior wear resistance and tensile strength compared to annealed titanium. This makes non-annealed titanium ideal for applications requiring structural integrity and minimal deformation under stress.

Cost Analysis: Annealed vs Non-Annealed

Annealed titanium generally incurs higher production costs due to the additional heat treatment process that improves ductility and reduces hardness, making it more suitable for complex machining and forming operations. Non-annealed titanium, lacking this heat treatment, is typically less expensive but may require more precision during machining to avoid brittleness and cracking, potentially increasing operational costs. Overall, annealed titanium offers cost efficiency in manufacturing stages where flexibility and toughness reduce tool wear and waste, whereas non-annealed titanium may be favored for applications prioritizing material strength at a lower upfront cost.

Selecting the Right Titanium for Your Project

Annealed titanium offers enhanced flexibility and improved machinability, making it ideal for projects requiring intricate shaping or forming. Non-annealed titanium provides superior strength and wear resistance, suitable for applications where maximum durability is essential. Selecting the right titanium depends on balancing mechanical requirements with fabrication processes to achieve optimal performance and longevity.

Future Trends in Titanium Heat Treatment

Emerging advancements in titanium heat treatment emphasize precise control over annealing processes to enhance mechanical properties and corrosion resistance tailored for aerospace and biomedical applications. The development of smart, adaptive annealing techniques utilizing real-time temperature monitoring and AI-driven control systems is poised to optimize grain structure refinement, improving fatigue strength in both annealed and non-annealed titanium. Future trends indicate a growing preference for energy-efficient, environmentally sustainable heat treatment methods that maintain the intrinsic benefits of titanium's lightweight and high-performance characteristics.

Annealed Titanium vs Non-Annealed Titanium Infographic

materialdif.com

materialdif.com