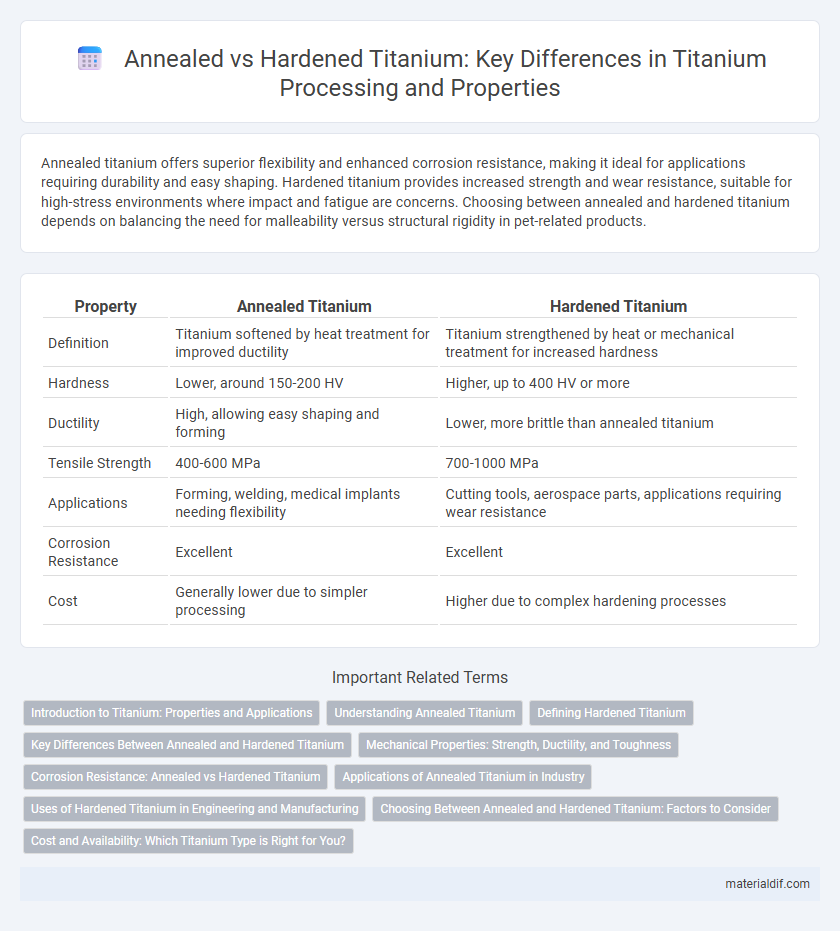

Annealed titanium offers superior flexibility and enhanced corrosion resistance, making it ideal for applications requiring durability and easy shaping. Hardened titanium provides increased strength and wear resistance, suitable for high-stress environments where impact and fatigue are concerns. Choosing between annealed and hardened titanium depends on balancing the need for malleability versus structural rigidity in pet-related products.

Table of Comparison

| Property | Annealed Titanium | Hardened Titanium |

|---|---|---|

| Definition | Titanium softened by heat treatment for improved ductility | Titanium strengthened by heat or mechanical treatment for increased hardness |

| Hardness | Lower, around 150-200 HV | Higher, up to 400 HV or more |

| Ductility | High, allowing easy shaping and forming | Lower, more brittle than annealed titanium |

| Tensile Strength | 400-600 MPa | 700-1000 MPa |

| Applications | Forming, welding, medical implants needing flexibility | Cutting tools, aerospace parts, applications requiring wear resistance |

| Corrosion Resistance | Excellent | Excellent |

| Cost | Generally lower due to simpler processing | Higher due to complex hardening processes |

Introduction to Titanium: Properties and Applications

Annealed titanium exhibits enhanced ductility and corrosion resistance due to its softening heat treatment, making it ideal for intricate aerospace components and biomedical implants. Hardened titanium undergoes processes like cold working or alloying to increase strength and hardness, providing superior performance in high-stress environments such as military armor and industrial machinery. Understanding the distinct properties of annealed versus hardened titanium enables optimized application-specific material selection in engineering and manufacturing.

Understanding Annealed Titanium

Annealed titanium exhibits increased ductility and reduced hardness due to a heat treatment process that relieves internal stresses and refines its microstructure. This form of titanium is ideal for applications requiring extensive forming and shaping, as its enhanced malleability prevents cracking during fabrication. The annealing process improves corrosion resistance and stabilizes mechanical properties, making annealed titanium suitable for aerospace, medical implants, and chemical processing industries.

Defining Hardened Titanium

Hardened titanium undergoes heat treatment processes such as aging or cold working to increase its strength and hardness, enhancing its resistance to wear and deformation compared to annealed titanium. This treatment alters the microstructure of titanium alloys, typically by precipitating strengthening phases like alpha or beta, resulting in improved mechanical properties critical for aerospace and industrial applications. In contrast, annealed titanium features a softer, more ductile structure due to controlled cooling, offering better formability but lower tensile strength and hardness.

Key Differences Between Annealed and Hardened Titanium

Annealed titanium undergoes a heat treatment process that softens the metal, enhancing its ductility and making it easier to machine or form, while hardened titanium is subjected to cold working or aging treatments to increase its strength and hardness. The key difference lies in mechanical properties: annealed titanium offers greater flexibility and impact resistance, whereas hardened titanium provides superior tensile strength and wear resistance. Annealed titanium is ideal for intricate fabrication, whereas hardened titanium suits high-stress applications requiring durability.

Mechanical Properties: Strength, Ductility, and Toughness

Annealed titanium exhibits lower strength but higher ductility and toughness, making it suitable for applications requiring flexibility and resistance to impact. Hardened titanium, achieved through heat treatment or cold working, significantly increases tensile strength and hardness but reduces ductility and toughness, enhancing wear resistance and load-bearing capacity. The choice between annealed and hardened titanium depends on balancing mechanical properties to meet specific engineering requirements.

Corrosion Resistance: Annealed vs Hardened Titanium

Annealed titanium exhibits superior corrosion resistance due to its softer microstructure and lower dislocation density, which reduces susceptibility to corrosive attack. Hardened titanium, while offering enhanced mechanical strength, may experience localized decreases in corrosion resistance because of residual stresses and microstructural changes induced during hardening. Both forms maintain excellent resistance to oxidation and chemical degradation, but annealed titanium is generally preferred in highly corrosive environments.

Applications of Annealed Titanium in Industry

Annealed titanium exhibits excellent ductility and corrosion resistance, making it ideal for aerospace components, chemical processing equipment, and medical implants. Its softness allows easy machining and forming, essential for creating complex parts such as aircraft airframes and surgical tools. Industrial sectors favor annealed titanium for applications requiring high strength-to-weight ratios combined with durability in harsh environments.

Uses of Hardened Titanium in Engineering and Manufacturing

Hardened titanium exhibits superior strength, wear resistance, and fatigue durability compared to annealed titanium, making it ideal for aerospace components, automotive parts, and medical implants. Its enhanced hardness allows precise machining and prolonged lifespan in demanding environments, such as turbine blades, engine valves, and surgical instruments. Manufacturers rely on hardened titanium to optimize performance and reduce maintenance in critical engineering applications.

Choosing Between Annealed and Hardened Titanium: Factors to Consider

Choosing between annealed and hardened titanium depends on the specific application requirements, including mechanical strength, flexibility, and corrosion resistance. Annealed titanium offers superior ductility and ease of machining, making it ideal for components requiring intricate shaping and toughness under stress. Hardened titanium provides enhanced hardness and wear resistance, suitable for high-stress environments where durability and strength are critical factors.

Cost and Availability: Which Titanium Type is Right for You?

Annealed titanium generally costs less and is more widely available due to its softer, more workable nature, making it ideal for applications requiring flexibility and easier fabrication. Hardened titanium, processed through heat treatment or cold working to increase strength, typically commands a higher price and may have limited availability depending on the specific alloy and hardness level needed. Selecting the right titanium type depends on balancing budget constraints with performance requirements, where annealed titanium suits cost-sensitive projects and hardened titanium fits high-strength, durability-critical uses.

Annealed Titanium vs Hardened Titanium Infographic

materialdif.com

materialdif.com