Annealed titanium offers enhanced ductility and easier machinability due to its softened microstructure, making it ideal for intricate pet accessory designs requiring flexibility. Solution treated titanium undergoes heat treatment that increases strength and corrosion resistance, ensuring durable and long-lasting pet products exposed to harsh environments. Choosing between annealed and solution treated titanium depends on balancing the need for formability versus mechanical performance in pet applications.

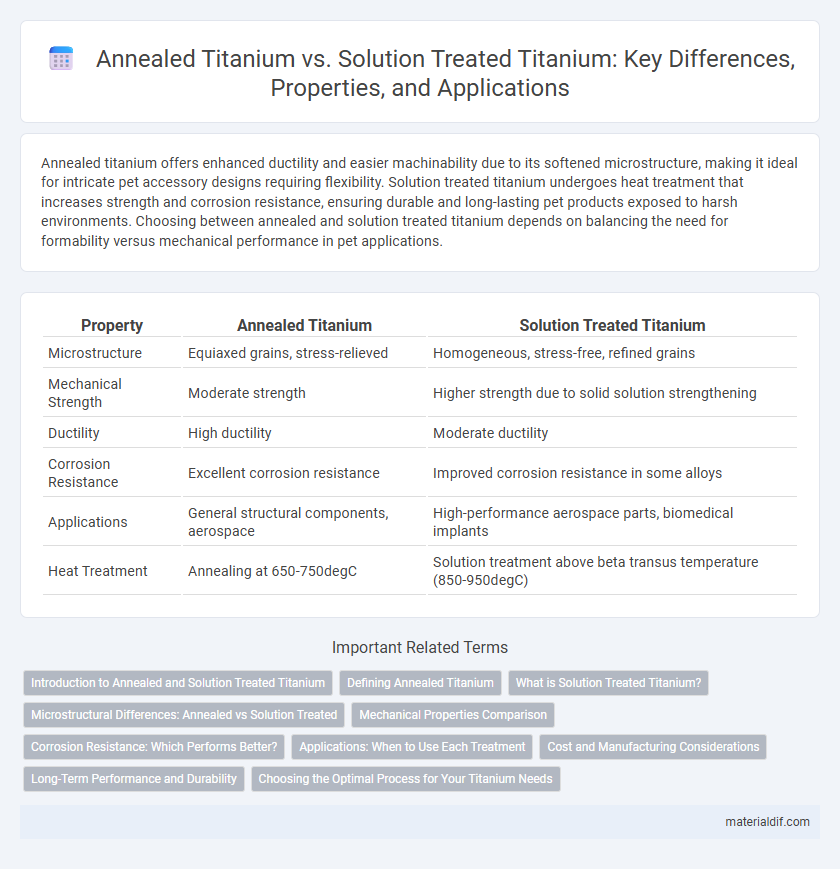

Table of Comparison

| Property | Annealed Titanium | Solution Treated Titanium |

|---|---|---|

| Microstructure | Equiaxed grains, stress-relieved | Homogeneous, stress-free, refined grains |

| Mechanical Strength | Moderate strength | Higher strength due to solid solution strengthening |

| Ductility | High ductility | Moderate ductility |

| Corrosion Resistance | Excellent corrosion resistance | Improved corrosion resistance in some alloys |

| Applications | General structural components, aerospace | High-performance aerospace parts, biomedical implants |

| Heat Treatment | Annealing at 650-750degC | Solution treatment above beta transus temperature (850-950degC) |

Introduction to Annealed and Solution Treated Titanium

Annealed titanium undergoes a heat treatment process that softens the metal, enhancing its ductility and making it easier to machine or form without compromising corrosion resistance. Solution treated titanium involves heating the alloy to a high temperature followed by rapid cooling, which stabilizes the microstructure and improves strength and fatigue resistance. Both annealed and solution treated titanium are critical for applications requiring a balance of mechanical properties and corrosion resistance in aerospace, biomedical, and industrial fields.

Defining Annealed Titanium

Annealed titanium undergoes a controlled heat treatment process that softens the metal, enhancing its ductility and reducing internal stresses without altering its primary microstructure. This treatment improves machinability and formability, making it suitable for applications requiring precise shaping and bending. In contrast to solution treated titanium, annealed titanium offers enhanced toughness but lower strength due to its recrystallized grains.

What is Solution Treated Titanium?

Solution treated titanium undergoes a heat treatment process where the alloy is heated to a high temperature and rapidly cooled to dissolve secondary phases, enhancing its strength and corrosion resistance. This treatment refines the microstructure by producing a uniform alpha phase, improving mechanical properties compared to annealed titanium. Solution treated titanium is preferred in aerospace and medical applications for its superior toughness and durability.

Microstructural Differences: Annealed vs Solution Treated

Annealed titanium exhibits a homogeneous microstructure with equiaxed grains resulting from slow cooling, enhancing ductility and toughness. Solution treated titanium undergoes rapid quenching from the beta phase, producing a martensitic or fine alpha-prime microstructure that improves strength and hardness. The primary microstructural difference lies in grain size and phase distribution, directly influencing mechanical properties and performance in applications.

Mechanical Properties Comparison

Annealed titanium exhibits improved ductility and lower tensile strength compared to solution treated titanium, which provides higher yield strength and enhanced hardness due to its refined microstructure. The solution treatment process strengthens titanium by dissolving alloying elements into a solid solution, resulting in superior mechanical performance under stress and fatigue conditions. Annealed titanium is preferred for applications requiring formability, while solution treated titanium is ideal where maximum strength and wear resistance are critical.

Corrosion Resistance: Which Performs Better?

Annealed titanium exhibits superior corrosion resistance in environments with fluctuating temperatures and mechanical stresses due to its stabilized microstructure. Solution treated titanium, while offering high strength, can be more susceptible to localized corrosion if improperly heat-treated or exposed to aggressive media. For applications requiring optimal corrosion resistance, annealed titanium typically outperforms solution treated variants, especially in marine or chemical processing environments.

Applications: When to Use Each Treatment

Annealed titanium offers enhanced ductility and toughness, making it ideal for complex forming processes and applications such as aerospace components, medical implants, and automotive parts where shaping and flexibility are critical. Solution treated titanium provides superior strength and corrosion resistance, suited for high-performance environments like chemical processing, marine applications, and heat exchangers requiring durability under stress and corrosive conditions. Selecting annealed or solution treated titanium depends on balancing the need for formability versus mechanical strength and environmental resistance in the intended application.

Cost and Manufacturing Considerations

Annealed titanium offers lower manufacturing costs due to simpler heat treatment and reduced processing time, making it favorable for large-scale production where mechanical properties are less critical. Solution treated titanium involves higher expenses driven by precise temperature control and quenching processes, enhancing strength and corrosion resistance for specialized applications. Selecting between annealed and solution treated titanium depends on balancing cost efficiency with performance requirements in aerospace, medical implants, and automotive industries.

Long-Term Performance and Durability

Annealed titanium exhibits enhanced ductility and stress relief, making it ideal for applications requiring flexibility and resistance to crack initiation over time. Solution treated titanium undergoes heat treatment to dissolve precipitates, resulting in improved strength and corrosion resistance, which contributes to superior long-term durability in harsh environments. The choice between annealed and solution treated titanium depends on the balance between mechanical performance and environmental longevity required for specific applications.

Choosing the Optimal Process for Your Titanium Needs

Annealed titanium offers improved ductility and toughness by relieving internal stresses through controlled heating and slow cooling, making it ideal for applications requiring enhanced formability and weldability. Solution treated titanium undergoes rapid quenching from high temperatures to create a uniform microstructure, resulting in superior strength and corrosion resistance, suitable for aerospace and medical implants. Selecting the optimal process depends on balancing requirements for strength, durability, and fabrication ease specific to your titanium application.

Annealed Titanium vs Solution Treated Titanium Infographic

materialdif.com

materialdif.com