Titanium powder offers greater versatility in manufacturing complex shapes and intricate designs through additive manufacturing, while titanium billet provides superior strength and durability for traditional machining processes. The choice between titanium powder and billet depends on the specific application requirements, balancing between lightweight customization and structural integrity. Titanium powder enables efficient material usage with minimal waste, whereas billet ensures consistent grain structure and mechanical properties.

Table of Comparison

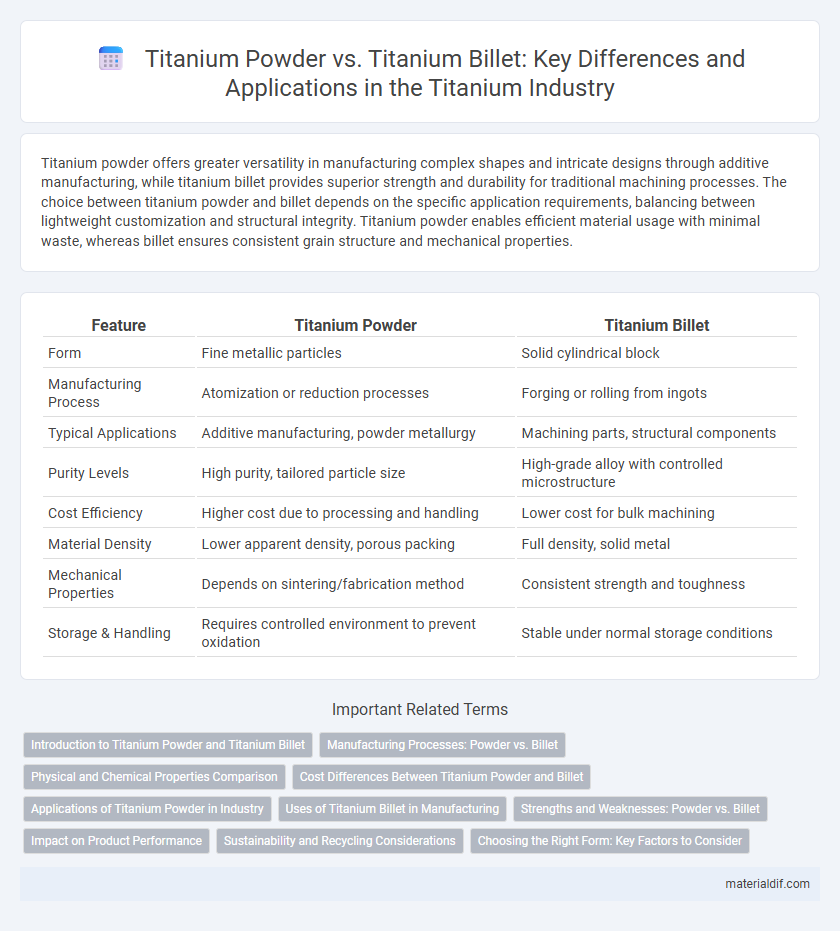

| Feature | Titanium Powder | Titanium Billet |

|---|---|---|

| Form | Fine metallic particles | Solid cylindrical block |

| Manufacturing Process | Atomization or reduction processes | Forging or rolling from ingots |

| Typical Applications | Additive manufacturing, powder metallurgy | Machining parts, structural components |

| Purity Levels | High purity, tailored particle size | High-grade alloy with controlled microstructure |

| Cost Efficiency | Higher cost due to processing and handling | Lower cost for bulk machining |

| Material Density | Lower apparent density, porous packing | Full density, solid metal |

| Mechanical Properties | Depends on sintering/fabrication method | Consistent strength and toughness |

| Storage & Handling | Requires controlled environment to prevent oxidation | Stable under normal storage conditions |

Introduction to Titanium Powder and Titanium Billet

Titanium powder consists of fine particles produced through processes like gas atomization or hydride-dehydride, offering high surface area and versatility for additive manufacturing and powder metallurgy applications. Titanium billet is a solid, forged cylindrical mass typically used for traditional machining and fabrication, providing superior structural integrity and mechanical properties. Each form serves distinct industrial purposes, with powder enabling complex shapes and billets supporting high-strength, precision components.

Manufacturing Processes: Powder vs. Billet

Titanium powder is produced through processes like atomization or hydride-dehydride, enabling precise control over particle size and composition, ideal for additive manufacturing and powder metallurgy. Titanium billets are formed by casting or forging solid ingots, resulting in dense, homogeneous blocks suitable for traditional subtractive machining and shaping. The powder process allows complex geometries and minimal waste, while billets offer superior mechanical properties for high-stress applications.

Physical and Chemical Properties Comparison

Titanium powder exhibits a higher surface area and increased reactivity compared to titanium billets, which are dense, solid forms with low surface area. Chemically, titanium powder is more prone to oxidation due to particle size and exposure, while billets maintain greater corrosion resistance and structural stability. Physically, billets possess superior mechanical strength and ductility, whereas powder is advantageous for additive manufacturing and alloy production due to its form and reactive surface.

Cost Differences Between Titanium Powder and Billet

Titanium powder generally incurs higher production costs due to complex atomization and purification processes compared to titanium billet, which is produced by melting and solidifying raw titanium for simpler machining. The scalability of billet manufacturing often results in lower per-unit costs, making billets more cost-effective for large structural components. However, titanium powder offers material flexibility for additive manufacturing, potentially reducing machining waste and assembly costs despite its premium price.

Applications of Titanium Powder in Industry

Titanium powder is extensively used in additive manufacturing, aerospace components, and biomedical implants due to its ability to produce complex geometries with high strength-to-weight ratios. Unlike titanium billet, which requires machining and is limited to simpler shapes, titanium powder allows for precise control over porosity and microstructure, enhancing performance in automotive and chemical processing industries. The versatility of titanium powder in powder metallurgy and 3D printing facilitates cost-effective production of custom aerospace parts and medical devices with improved fatigue resistance and biocompatibility.

Uses of Titanium Billet in Manufacturing

Titanium billet is extensively used in manufacturing aerospace components, medical implants, and high-performance automotive parts due to its superior strength and corrosion resistance. Its solid form allows precision machining into complex shapes for structural applications where durability and weight reduction are critical. Manufacturers prefer titanium billets for producing custom parts with consistent mechanical properties and excellent surface finishes.

Strengths and Weaknesses: Powder vs. Billet

Titanium powder offers superior versatility for complex geometries and additive manufacturing, enabling lightweight components with fine microstructures that enhance strength-to-weight ratios. However, powder processing presents challenges such as higher production costs, potential contamination, and porosity issues that can affect mechanical integrity. In contrast, titanium billets provide uniform material properties, excellent ductility, and high fatigue resistance, but are limited by machining constraints and higher material wastage during shaping.

Impact on Product Performance

Titanium powder offers superior flexibility for additive manufacturing, enabling complex geometries and enhanced material utilization, which significantly improves product performance in aerospace and biomedical applications. In contrast, titanium billets deliver higher density and structural integrity, making them ideal for high-strength components requiring excellent fatigue resistance. Selecting between titanium powder and billet depends on the specific performance requirements, such as weight reduction, mechanical strength, and manufacturing precision.

Sustainability and Recycling Considerations

Titanium powder enables more efficient material usage and reduced waste through additive manufacturing, promoting sustainability by minimizing scrap compared to traditional titanium billet machining. Recycling titanium powder can be challenging due to potential oxidation during storage and reuse, while titanium billets offer a more straightforward recycling process through remelting and reshaping. Choosing between titanium powder and billets for sustainable production depends on balancing waste reduction potential with the complexities of powder recycling and reuse.

Choosing the Right Form: Key Factors to Consider

Titanium powder offers superior versatility for additive manufacturing and complex geometries, enabling lightweight designs with high strength-to-weight ratios, while titanium billets provide excellent material integrity and are ideal for machining large, structural components requiring uniform grain structure. Key factors to consider when choosing between titanium powder and billets include the intended application, production method, mechanical property requirements, and cost efficiency. Understanding the trade-offs in material density, surface finish, and production lead times is essential for optimizing performance and manufacturing outcomes.

Titanium Powder vs Titanium Billet Infographic

materialdif.com

materialdif.com