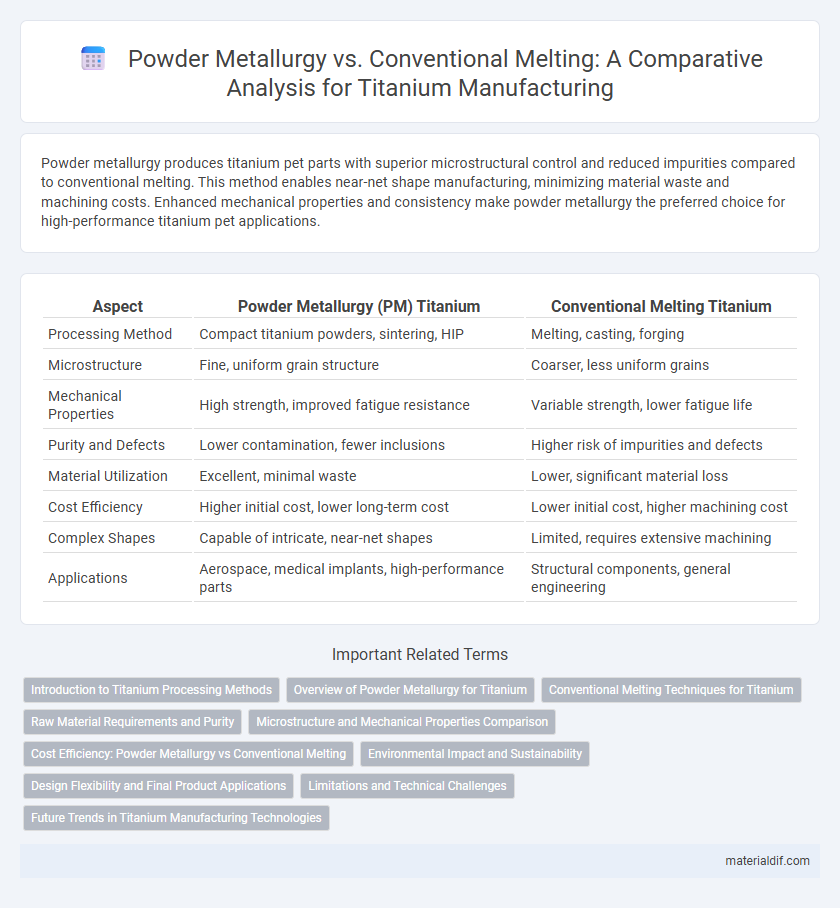

Powder metallurgy produces titanium pet parts with superior microstructural control and reduced impurities compared to conventional melting. This method enables near-net shape manufacturing, minimizing material waste and machining costs. Enhanced mechanical properties and consistency make powder metallurgy the preferred choice for high-performance titanium pet applications.

Table of Comparison

| Aspect | Powder Metallurgy (PM) Titanium | Conventional Melting Titanium |

|---|---|---|

| Processing Method | Compact titanium powders, sintering, HIP | Melting, casting, forging |

| Microstructure | Fine, uniform grain structure | Coarser, less uniform grains |

| Mechanical Properties | High strength, improved fatigue resistance | Variable strength, lower fatigue life |

| Purity and Defects | Lower contamination, fewer inclusions | Higher risk of impurities and defects |

| Material Utilization | Excellent, minimal waste | Lower, significant material loss |

| Cost Efficiency | Higher initial cost, lower long-term cost | Lower initial cost, higher machining cost |

| Complex Shapes | Capable of intricate, near-net shapes | Limited, requires extensive machining |

| Applications | Aerospace, medical implants, high-performance parts | Structural components, general engineering |

Introduction to Titanium Processing Methods

Powder metallurgy and conventional melting are two primary methods for processing titanium, each impacting material properties and application scope. Powder metallurgy involves producing titanium components through powder consolidation, enabling superior control over microstructure and reduced material wastage compared to conventional melting, which relies on melting and casting titanium ingots. This distinction in processing methods influences mechanical strength, corrosion resistance, and cost-effectiveness in aerospace, medical, and industrial applications.

Overview of Powder Metallurgy for Titanium

Powder metallurgy for titanium involves producing titanium components by compacting and sintering metal powders, offering superior control over microstructure and properties compared to conventional melting methods. This process reduces material wastage, enhances mechanical performance, and allows for complex geometries that are difficult to achieve with cast or wrought titanium. Powder metallurgy also minimizes contamination and oxidation risks due to the low processing temperatures and controlled environments used during sintering.

Conventional Melting Techniques for Titanium

Conventional melting techniques for titanium, such as vacuum arc remelting (VAR) and plasma arc melting (PAM), provide high purity and control over alloy composition, essential for aerospace and biomedical applications. These methods ensure the elimination of impurities and achieve a homogenous microstructure, enhancing mechanical properties and corrosion resistance. Unlike powder metallurgy, conventional melting is preferred for large component production due to its scalability and cost-effectiveness.

Raw Material Requirements and Purity

Powder metallurgy for titanium requires high-purity sponge or hydride-dehydride powders to minimize oxygen, nitrogen, and carbon contamination, ensuring superior mechanical properties and corrosion resistance. Conventional melting typically utilizes titanium scrap and sponge material but presents challenges in controlling impurities due to exposure to air and furnace environments. The controlled atmosphere and particle size distribution in powder metallurgy enable tighter compositional control and higher purity levels compared to conventional melting processes.

Microstructure and Mechanical Properties Comparison

Powder metallurgy titanium exhibits a finer and more uniform microstructure compared to conventional melting, resulting in enhanced mechanical properties such as higher tensile strength and improved fatigue resistance. The absence of casting defects like porosity and segregation in powder metallurgy contributes to superior performance under cyclic loading conditions. Grain refinement achieved through powder processing leads to increased hardness and better ductility relative to traditionally melted titanium alloys.

Cost Efficiency: Powder Metallurgy vs Conventional Melting

Powder metallurgy offers superior cost efficiency over conventional melting by minimizing material wastage through near-net-shape processing and reducing energy consumption during manufacturing. The process allows for precise control over alloy composition and microstructure, leading to lower post-processing costs and improved mechanical properties. In contrast, conventional melting involves higher scrap rates and energy inputs, resulting in increased production expenses and longer lead times.

Environmental Impact and Sustainability

Powder metallurgy of titanium significantly reduces waste by enabling near-net shape manufacturing, minimizing material scrap compared to conventional melting processes that often result in higher offcuts and energy consumption. The lower processing temperatures and energy requirements in powder metallurgy lead to reduced carbon emissions, making it a more sustainable option for titanium production. This technique also supports recycling of titanium powders, further enhancing environmental benefits and contributing to circular economy goals in aerospace and medical industries.

Design Flexibility and Final Product Applications

Titanium powder metallurgy offers superior design flexibility compared to conventional melting, enabling the production of complex geometries and customized components with minimal material waste. This method supports advanced applications in aerospace, biomedical implants, and automotive sectors where precision and lightweight properties are critical. Conventional melting remains prevalent for large-scale, simpler shapes but lacks the ability to efficiently produce intricate or near-net-shape titanium parts.

Limitations and Technical Challenges

Powder metallurgy of titanium faces challenges such as powder contamination, limited powder availability, and high production costs compared to conventional melting methods. Conventional melting techniques struggle with defects like segregation and grain growth, impacting mechanical properties and limiting design complexity. Both approaches require advanced control over processing parameters to optimize material performance and minimize impurities.

Future Trends in Titanium Manufacturing Technologies

Powder metallurgy in titanium manufacturing enables precise control over microstructure and mechanical properties, promoting superior performance in aerospace and biomedical applications compared to conventional melting. Future trends emphasize additive manufacturing integration, enhanced powder recycling methods, and tailored alloy compositions to reduce cost while improving sustainability. Advancements in high-energy milling and spark plasma sintering are driving innovation by facilitating the production of complex, near-net-shape titanium components with minimized waste.

Powder Metallurgy vs Conventional Melting Infographic

materialdif.com

materialdif.com