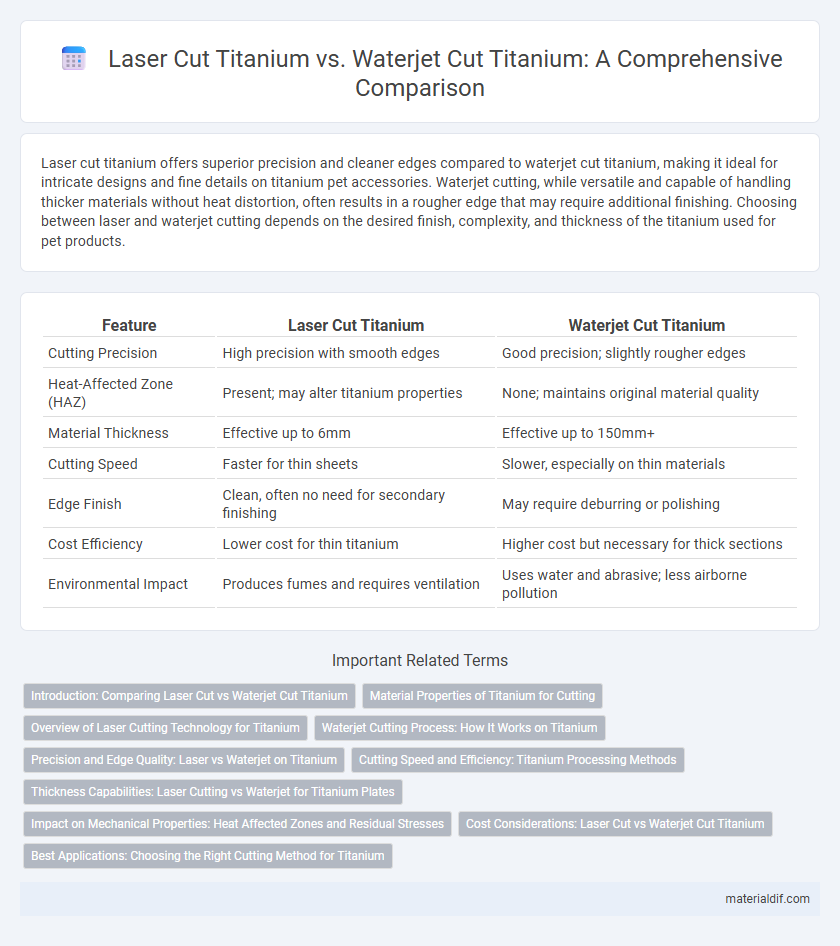

Laser cut titanium offers superior precision and cleaner edges compared to waterjet cut titanium, making it ideal for intricate designs and fine details on titanium pet accessories. Waterjet cutting, while versatile and capable of handling thicker materials without heat distortion, often results in a rougher edge that may require additional finishing. Choosing between laser and waterjet cutting depends on the desired finish, complexity, and thickness of the titanium used for pet products.

Table of Comparison

| Feature | Laser Cut Titanium | Waterjet Cut Titanium |

|---|---|---|

| Cutting Precision | High precision with smooth edges | Good precision; slightly rougher edges |

| Heat-Affected Zone (HAZ) | Present; may alter titanium properties | None; maintains original material quality |

| Material Thickness | Effective up to 6mm | Effective up to 150mm+ |

| Cutting Speed | Faster for thin sheets | Slower, especially on thin materials |

| Edge Finish | Clean, often no need for secondary finishing | May require deburring or polishing |

| Cost Efficiency | Lower cost for thin titanium | Higher cost but necessary for thick sections |

| Environmental Impact | Produces fumes and requires ventilation | Uses water and abrasive; less airborne pollution |

Introduction: Comparing Laser Cut vs Waterjet Cut Titanium

Laser cut titanium offers precise, high-speed machining with minimal thermal distortion, making it ideal for intricate designs and thin materials. Waterjet cut titanium provides a cold cutting process that prevents heat-affected zones, delivering smooth edges suitable for thicker or more heat-sensitive titanium components. Comparing these methods highlights laser cutting's efficiency and detail advantage against waterjet's versatility and superior edge quality in titanium fabrication.

Material Properties of Titanium for Cutting

Laser cut titanium exhibits superior edge precision and minimal thermal distortion, preserving the metal's inherent strength and corrosion resistance vital for aerospace and medical applications. Waterjet cut titanium maintains the metal's crystalline structure due to the cold cutting process, ensuring no heat-affected zones and retaining maximum material toughness and fatigue resistance. Both methods preserve titanium's low density and high tensile strength, yet waterjet cutting excels in preventing microstructural changes that could compromise mechanical performance.

Overview of Laser Cutting Technology for Titanium

Laser cutting technology for titanium utilizes a high-powered laser beam that melts, burns, or vaporizes the material with extreme precision and minimal heat-affected zones. This method provides fast, clean cuts ideal for intricate designs and fine details in aerospace, medical implants, and automotive industries. Laser cutting achieves superior edge quality and reduced material waste compared to traditional mechanical cutting techniques, making it highly efficient for titanium fabrication.

Waterjet Cutting Process: How It Works on Titanium

Waterjet cutting titanium utilizes a high-pressure stream of water mixed with abrasive particles to precisely erode the metal without generating heat, preserving the material's structural integrity. This cold cutting process reduces the risk of thermal distortion and maintains the titanium's strength and corrosion resistance. The ability to cut complex shapes with minimal kerf makes waterjet cutting ideal for aerospace, medical, and industrial titanium components.

Precision and Edge Quality: Laser vs Waterjet on Titanium

Laser cut titanium offers exceptional precision with tightly controlled beam focus, enabling detailed and intricate shapes ideal for medical implants and aerospace components. Waterjet cut titanium provides a smoother edge quality with minimal thermal distortion, preserving the material's structural integrity and reducing the need for secondary finishing. Both methods excel in precision, but laser cutting achieves finer details, whereas waterjet cutting delivers superior edge finish and avoids heat-affected zones.

Cutting Speed and Efficiency: Titanium Processing Methods

Laser cut titanium offers faster cutting speeds compared to waterjet cut titanium due to its high precision and intense focused energy, enabling efficient processing in industrial applications. Waterjet cutting excels in minimizing heat-affected zones and material distortion, making it suitable for complex shapes despite slower cutting speeds. Selecting the appropriate titanium processing method depends on balancing cutting speed requirements with the desired edge quality and material integrity.

Thickness Capabilities: Laser Cutting vs Waterjet for Titanium Plates

Laser cutting titanium accommodates thinner plates typically up to 1/4 inch with high precision and minimal heat-affected zones, offering clean edges ideal for intricate designs. Waterjet cutting excels with thicker titanium plates, exceeding 1 inch in thickness, by using high-pressure abrasive water to achieve precise cuts without thermal distortion or material hardness alterations. The choice between laser and waterjet cutting titanium hinges on plate thickness requirements, with waterjet preferred for heavy-duty applications and laser cutting favored for finer, thin-gauge titanium work.

Impact on Mechanical Properties: Heat Affected Zones and Residual Stresses

Laser cut titanium often induces heat affected zones (HAZ) that can alter the metal's microstructure, leading to potential changes in hardness and tensile strength. In contrast, waterjet cutting minimizes thermal impact, preserving the original mechanical properties by avoiding HAZ formation. Residual stresses tend to be higher with laser cutting due to rapid heating and cooling cycles, whereas waterjet cutting generates lower residual stresses, resulting in improved dimensional stability and fatigue resistance.

Cost Considerations: Laser Cut vs Waterjet Cut Titanium

Laser cut titanium typically incurs higher initial equipment costs but offers faster processing speeds, which can lower long-term expenses for large production runs. Waterjet cut titanium demands less maintenance and avoids heat-affected zones, potentially reducing post-processing costs despite slower cutting speeds. Evaluating project volume and material specifications is critical when comparing cost efficiency between laser and waterjet titanium cutting methods.

Best Applications: Choosing the Right Cutting Method for Titanium

Laser cut titanium offers precise, clean edges ideal for intricate components in aerospace and medical implants, where tight tolerances and minimal thermal distortion are crucial. Waterjet cut titanium excels in thicker sections and complex shapes without heat-affected zones, making it suitable for heavy-duty industrial parts and architectural elements. Selecting between laser and waterjet cutting depends on material thickness, desired edge quality, and application-specific requirements such as heat sensitivity and production volume.

Laser Cut Titanium vs Waterjet Cut Titanium Infographic

materialdif.com

materialdif.com